Geological survey construction method and structure

A technology of geological survey and construction method, applied in the field of geological survey, can solve problems such as soil is easily washed away by rain, road traffic is greatly affected, iron plate displacement and deformation, etc., to ensure normal traffic, convenient excavation operation, reduce effect of influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

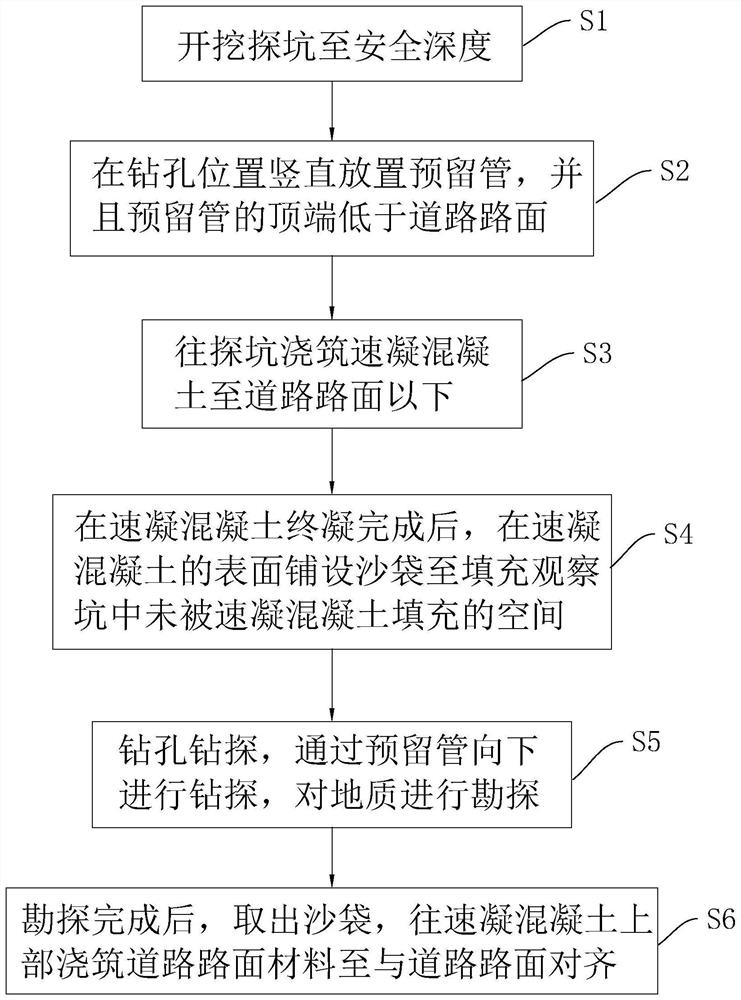

[0043] Embodiment 1: geological survey construction method, such as figure 1 shown, including the following steps:

[0044] S1: Excavate the exploration pit 1 to a safe depth, that is, delineate the excavation range with an area of 80cm*120cm at the position where drilling survey is required, and manually excavate the exploration pit 1 to 2.8m-3.2m within the excavation range ( Such as a safe depth of 3m), the buried depth of general urban pipelines is within this range. Excavation pit 1 can be excavated to this depth to ensure that the impact of drilling operations on urban pipelines can be avoided. Whether the position of the hole work will conflict with the original urban pipeline, if so, re-determine the drilling position and re-excavate the exploration pit 1, and the top of the exploration pit 1 will increase from the area of 80cm*120cm with the excavation depth Gradually decrease, the side length of the area covered by the bottom of the pit 1 must not be less than t...

Embodiment 2

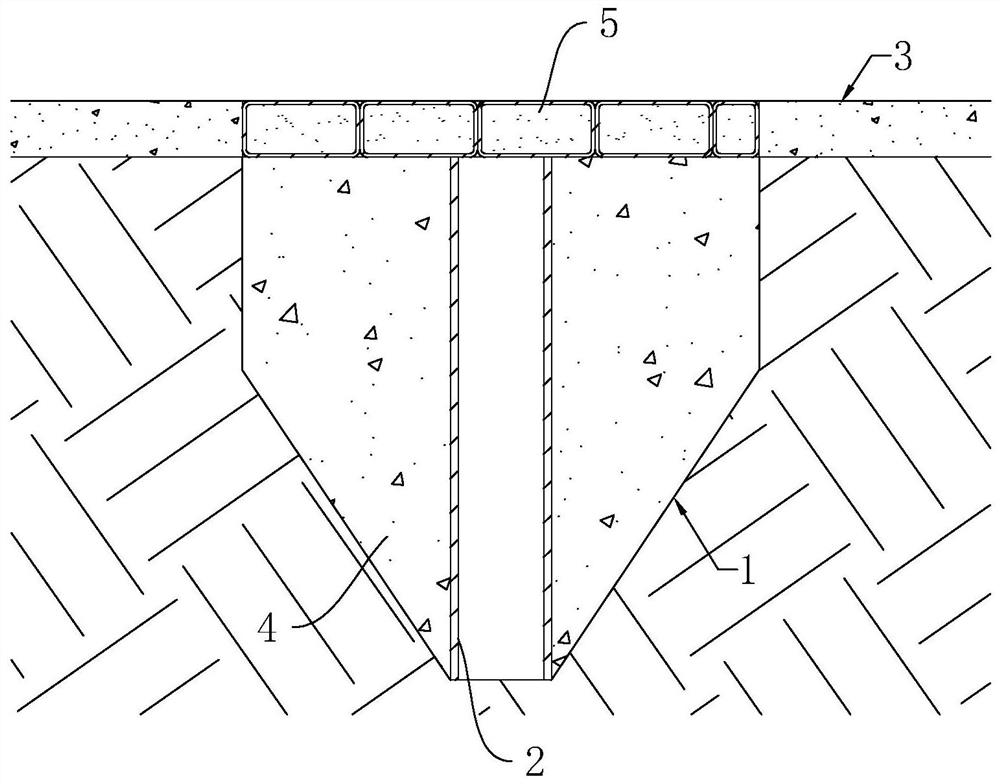

[0054] Embodiment 2: geological survey construction structure, such as figure 2 As shown, including the exploration pit 1 excavated on the road surface 3, the depth of the exploration pit 1 is 2.8m-3.2m (such as 3m), and the area of its top from 80cm*120cm gradually decreases with the increase of the excavation depth. The side length of the area covered by the bottom of the pit 1 is larger than the diameter of the reserved pipe 2 placed in the pit 1 subsequently, so that the reserved pipe 2 can smoothly touch the bottom of the pit 1 .

[0055] A reserved pipe 2 is vertically arranged in the exploration pit 1, the top of the reserved pipe 2 is lower than the road surface 3, and the distance between the top of the reserved pipe 2 and the road surface 3 is 28cm-32cm (such as 30cm). Stay pipe 2 selects PVC pipe or steel pipe for use, and its diameter is greater than the drilling tool diameter that carries out drilling operation.

[0056] Quick-setting concrete 4 is poured betw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com