Upper and lower plate cooling system and grinding and polishing device

A cooling system and cooling disc technology, which is applied in grinding/polishing safety devices, grinding/polishing equipment, metal processing equipment, etc., can solve the problems of unfavorable grinding disc cooling and poor cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

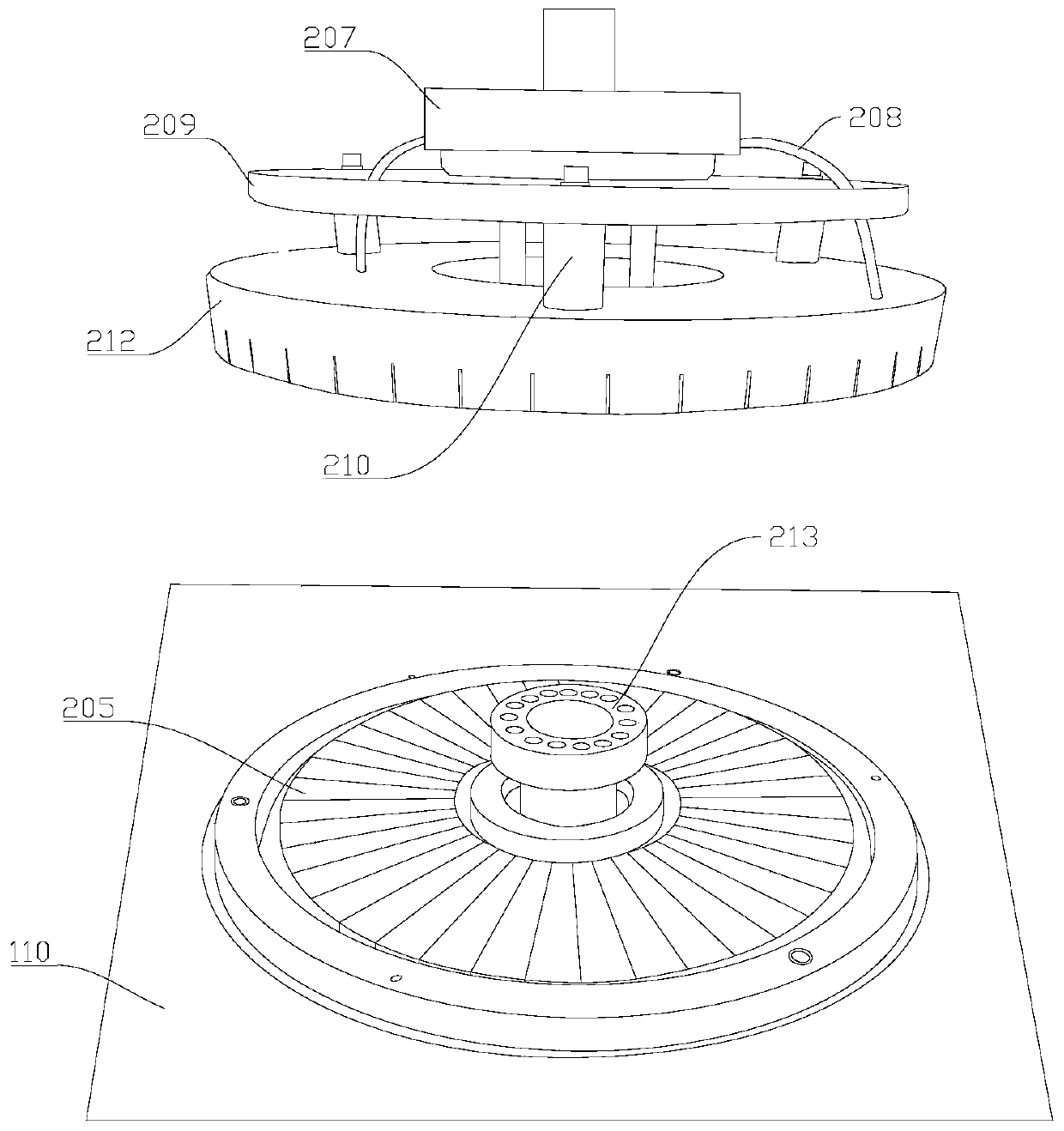

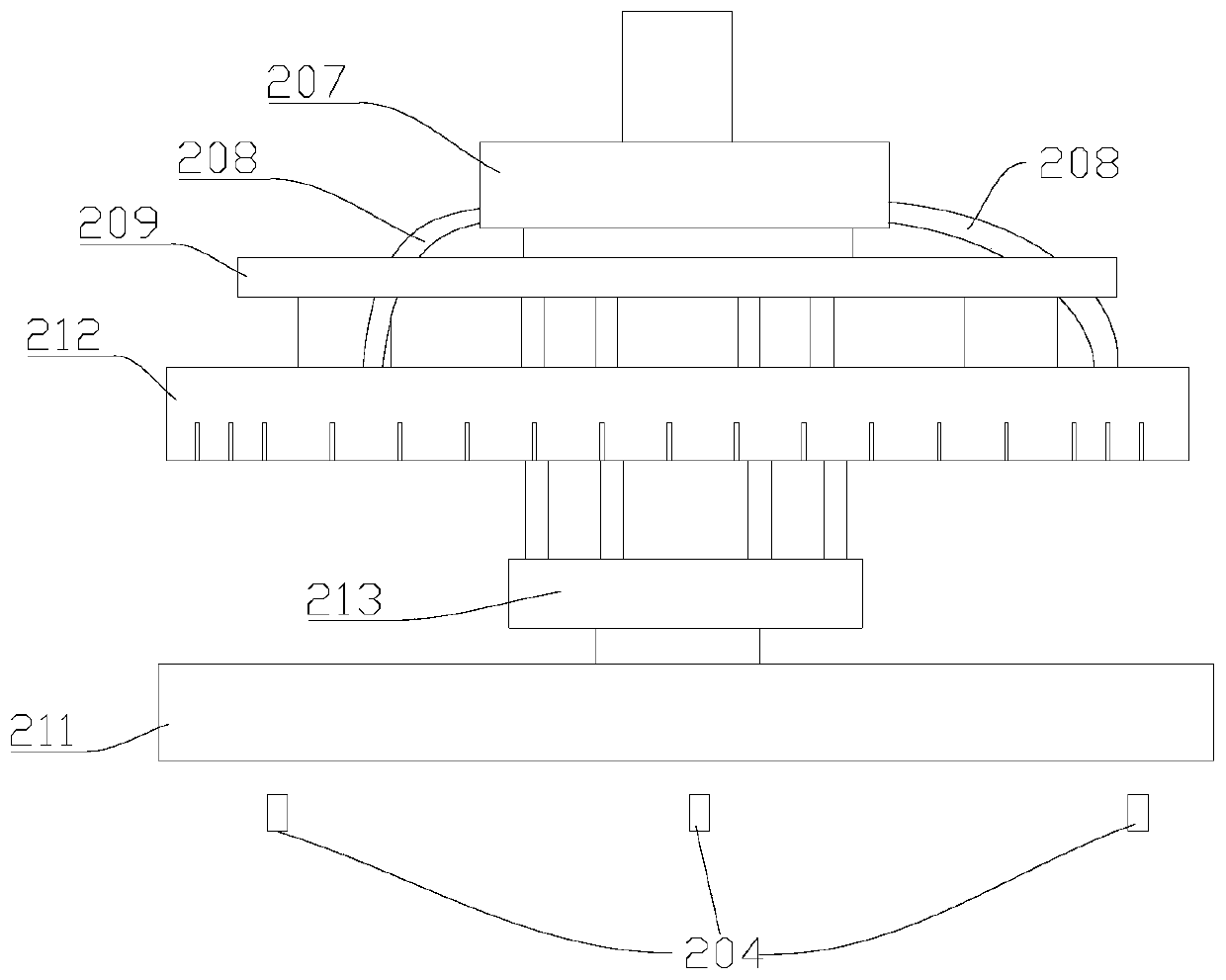

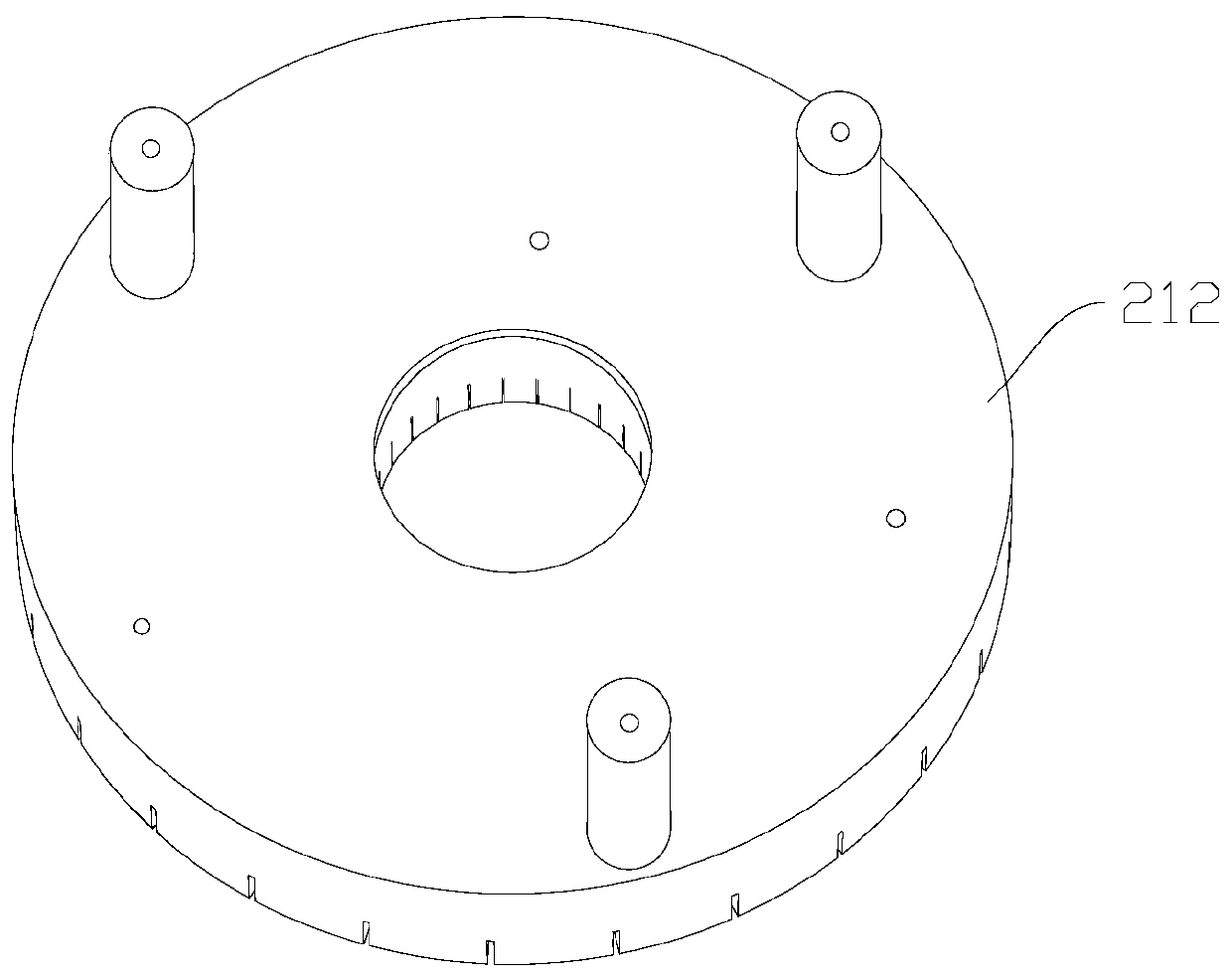

[0035] see Figure 1 to Figure 7 As shown, Embodiment 1 of the present invention provides an upper and lower plate cooling system, including a first cooling mechanism and a second cooling mechanism. The first cooling mechanism includes a plurality of first cooling plates 201 fixedly connected together, and a plurality of second cooling A cooling plate 201 is stacked up and down, that is to say, a plurality of first cooling plates 201 are stacked together from bottom to top; there is a cooling channel between two first cooling plates 201 adjacent up and down; a plurality of first cooling plates In 201, the lower end surface of the first cooling plate 201 located at the bottom is used to fix the upper disc grinding body, and the upper disc grinding body is provided with flow holes 203, and the flow holes 203 communicate with the cooling channel; the second cooling mechanism includes nozzles Assembly 204, the nozzle assembly 204 is arranged under the grinding body of the lower di...

Embodiment 2

[0049] Embodiment 2 of the present invention also provides a grinding and polishing device, including the upper and lower plate cooling system provided in Embodiment 1.

[0050] see Figure 10 and Figure 11 As shown, in the optional scheme of this embodiment, the grinding and polishing device also includes a polishing equipment box, and the polishing equipment box includes a revolving door, a box shell 109 and a workbench 110, and the box shell 109 is fixed on the table top of the workbench 110; The door is used to protect the cooling system of the upper and lower discs, that is to say, it can protect the grinding body of the upper disc and the grinding body of the lower disc during the grinding and polishing process.

[0051] see Figure 8 and Figure 9 As shown, the revolving door has the characteristics of small space occupation, safe and reliable use, and high space utilization rate. This revolving door comprises door body and support, and door body comprises top plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com