UV (Ultraviolet) curing system of thermal transfer ribbon

A thermal transfer printing, carbon ribbon technology, applied in printing, ink ribbon, chemical instruments and methods, etc., can solve the problems of difficult curing of the contained components, unfavorable environmental protection, air pollution, etc., so as to enhance market competitiveness and improve product quality. quality, the effect of preventing volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

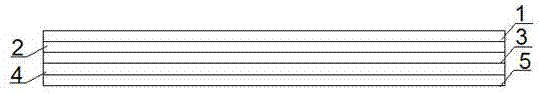

[0013] like figure 1 As shown, the present invention discloses a UV curing system for thermal transfer ribbons, including: BOPET film 1, release layer 2, UV layer 3, ink layer 4, adhesive layer 5, the inner side of the BOPET film 1 Coating a release layer 2, the outside of the release layer 2 is coated with a UV layer 3, the outside of the UV layer 3 is coated with an ink layer 4, and the outside of the ink layer 4 is coated with an adhesive layer 5.

[0014] The thickness of the BOPET film 1 is 4.5 μm.

[0015] The UV layer 3 is composed of the following raw materials in parts by weight: 70% acrylic resin, 20% photoinitiator, and 10% auxiliary agent.

[0016] The coating thickness of the UV layer 3 is 0.1-0.2 μm.

[0017] The present invention is implemented like this: in the process of making product, first take by weighing the solvent that is made up of following parts by weight: acrylic resin 70%, photoinitiator 20%, auxiliary agent 10%, this mixed solvent is dropped in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com