Artwork carving device

A kind of work and art technology, applied in the field of art, can solve the problems of scrapped art sculpture works, imperfect processing, and affecting the creation of finished products, etc., and achieve the effect of surface bottoming and engraving operations, convenient operation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

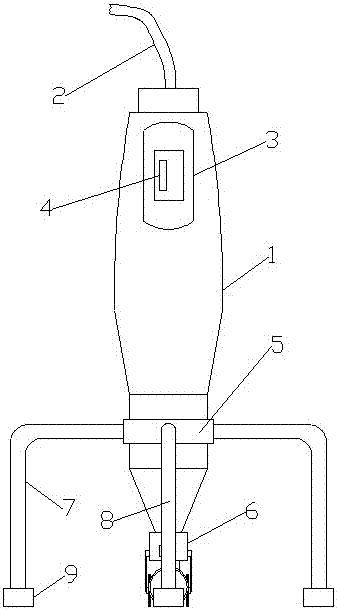

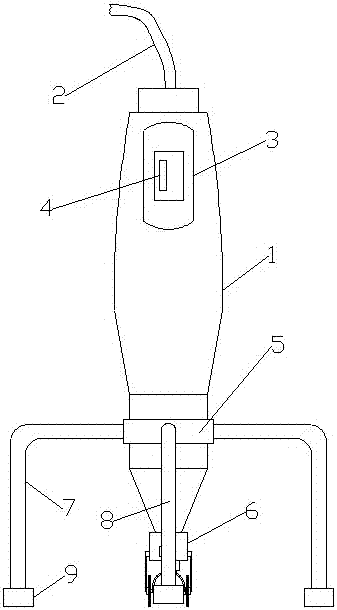

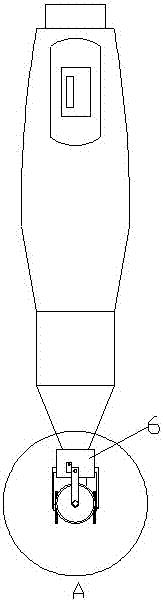

[0027] Embodiment 1: As shown in the figure, a kind of artwork engraving device comprises engraving hand-held body 1, the external power cord 2 that is connected with engraving hand-held body 1, the switch with control switch 4 that is installed on engraving hand-held body 1 top Box 3, a motor box 6 with a motor installed on the lower part of the engraving hand-held body 1, the lower part of the motor box 6 is provided with an external shaft mounting hole seat 13, and a first bevel gear 14 is installed in the external shaft mounting hole seat 13 , the first bevel gear 14 meshes with the second bevel gear 15, the center position of the second bevel gear 15 is sleeved with a rotating shaft 12, the two ends of the rotating shaft 12 are equipped with a first wheel saw 16, at the A bearing frame 11 is set on the rotating shaft 12 on the outside of the round saw 16, and the first round saw support frame 10 is installed in the bearing frame 11, and the top of the first round saw suppo...

Embodiment 2

[0029] Embodiment 2: As shown in the figure, a kind of artwork engraving device comprises engraving hand-held body 1, the external power cord 2 that is connected with engraving hand-held body 1, the switch with control switch 4 that is installed on engraving hand-held body 1 top Box 3, a motor box 6 with a motor installed on the lower part of the engraving hand-held body 1, the lower part of the motor box 6 is provided with an external shaft mounting hole seat 13, and a first bevel gear 14 is installed in the external shaft mounting hole seat 13 , the first bevel gear 14 meshes with the second bevel gear 15, the center position of the second bevel gear 15 is sleeved with a rotating shaft 12, the two ends of the rotating shaft 12 are equipped with a first wheel saw 16, at the A bearing frame 11 is set on the rotating shaft 12 on the outside of the round saw 16, and the first round saw support frame 10 is installed in the bearing frame 11, and the top of the first round saw suppo...

Embodiment 3

[0031] Embodiment 3: As shown in the figure, an engraving device for works of art includes an engraving hand-held body 1, an external power cord 2 connected to the engraving hand-held body 1, a switch with a control switch 4 installed on the top of the engraving hand-held body 1 Box 3, a motor box 6 with a motor installed on the lower part of the engraving hand-held body 1, the lower part of the motor box 6 is provided with an external shaft mounting hole seat 13, and a first bevel gear 14 is installed in the external shaft mounting hole seat 13 , the first bevel gear 14 meshes with the second bevel gear 15, the center position of the second bevel gear 15 is sleeved with a rotating shaft 12, the two ends of the rotating shaft 12 are equipped with a first wheel saw 16, at the A bearing frame 11 is set on the rotating shaft 12 on the outside of the round saw 16, and the first round saw support frame 10 is installed in the bearing frame 11, and the top of the first round saw suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com