A production process of sound-absorbing wood-plastic panel

A production process and technology of wood-plastic panels, which are applied to other household appliances, flat products, household appliances, etc., can solve the problems of life limitation, insufficient quality of wood-plastic panels, no sound absorption and sound insulation effects, etc., to achieve easier molding, The effect of reducing the probability of failure and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

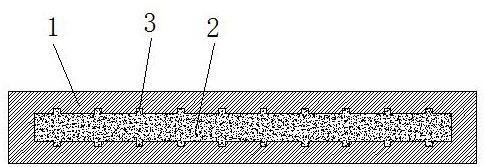

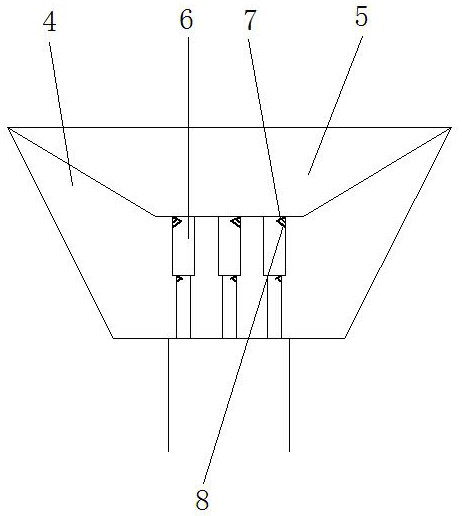

[0027] Embodiment: A kind of production technology of sound-absorbing wood-plastic panel, comprises the following steps:

[0028] 1) Wood-plastic material formula: according to the mass fraction, it includes 25% resin, 30% filler, 35% wood flour mixture, and 10% additives. The additives include stabilizers, lubricants, foaming agents, and coupling agents; The content of stabilizer, lubricant, foaming agent and coupling agent is 2.5% respectively; "filler" includes light calcium carbonate, heavy calcium carbonate and active calcium carbonate, and the ratio of the three is 1:1:1 , "Wood powder mixture" includes pine wood powder, straw powder and peanut shell powder, the ratio of the three is 3:2:1 respectively, pine wood powder, straw powder and peanut shell powder are from primary to secondary, adding straw powder and Peanut shell powder replaces part of the wood powder, which can greatly save costs, and the quality of the produced wood-plastic panels will not be affected. Whea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com