Microorganism negative-pressure surface soil reinforcement method

A technology of microorganisms and microbial bacterial liquids, applied in chemical instruments and methods, soil protection, building structures, etc., can solve the problems of low utilization rate of bacterial liquids and cementing materials, poor resistance to water flow erosion and wind erosion, and the thickness of the solidified soil layer Difficult to control and other issues to achieve the effect of avoiding erosion resistance failure, improving erosion resistance, and delaying the time of erosion flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] In this example, a microbial negative pressure surface soil stabilization method is used for sandy soil surface protection, the method includes the following steps:

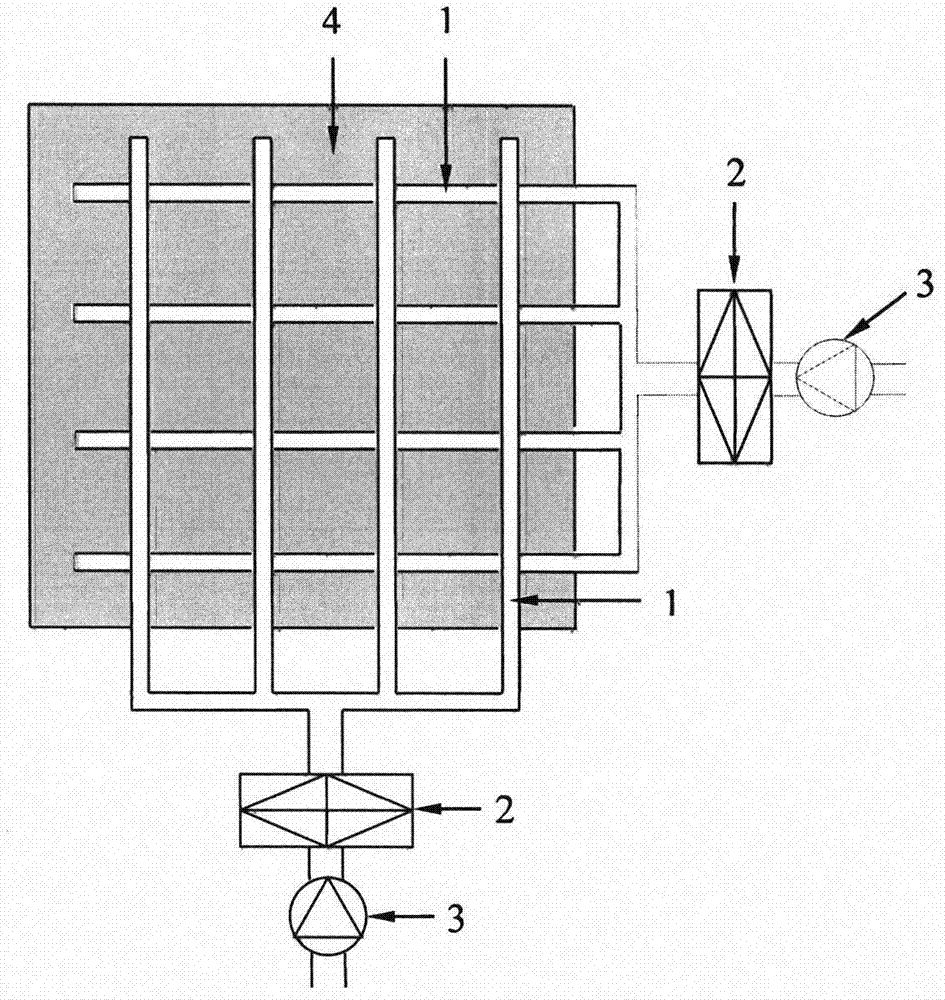

[0033] a. Buried negative pressure pipes 1 20cm below the surface of the soil body 4 to be reinforced, with a row spacing of 20cm, to form a negative pressure pipe network;

[0034] b. The concentration OD composed of Bacillus pasteurianus and culture medium 600 =1.5 microbial bacterial liquid, sprayed on the surface of the soil body 4 to be reinforced, and simultaneously turn on the vacuum pump 3 to extract the air and pore fluid in the soil body 4 to be reinforced through the negative pressure pipe 1, so as to accelerate the entry of the microbial bacterial liquid on the surface of the soil body 4 to be reinforced. Infiltration, when the bacterial liquid enters the negative pressure tube 1, turn off the vacuum pump 3 and let it stand for 4 hours;

[0035] c. Mix the pre-prepared 1.0mol / L urea and 1.0mol...

Embodiment 2

[0038] In this example, a method of microbial negative pressure surface soil consolidation is used for silt surface protection, and the method includes the following steps:

[0039] a. Buried negative pressure pipes 1 10cm below the surface of the soil body 4 to be reinforced with a row spacing of 20cm to form a negative pressure pipe network;

[0040] b. The concentration OD composed of Bacillus pasteurianus and culture medium 600 =1.5 microbial bacterial liquid, sprayed on the surface of the soil body 4 to be reinforced, and simultaneously turn on the vacuum pump 3 to extract the air and pore fluid in the soil body 4 to be reinforced through the negative pressure pipe 1, so as to accelerate the entry of the microbial bacterial liquid on the surface of the soil body 4 to be reinforced. Infiltration, when the bacterial liquid enters the negative pressure tube 1, turn off the vacuum pump 3 and let it stand for 8 hours;

[0041] c. Mix the pre-prepared 0.5mol / L urea and 0.5mol / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com