Interlayer lead-out structure for low-temperature container

A technology of extracting structure and low temperature container, which is applied to the outer wall of container structure, installation device of container structure, non-pressure container, etc. , to ensure the effect of thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

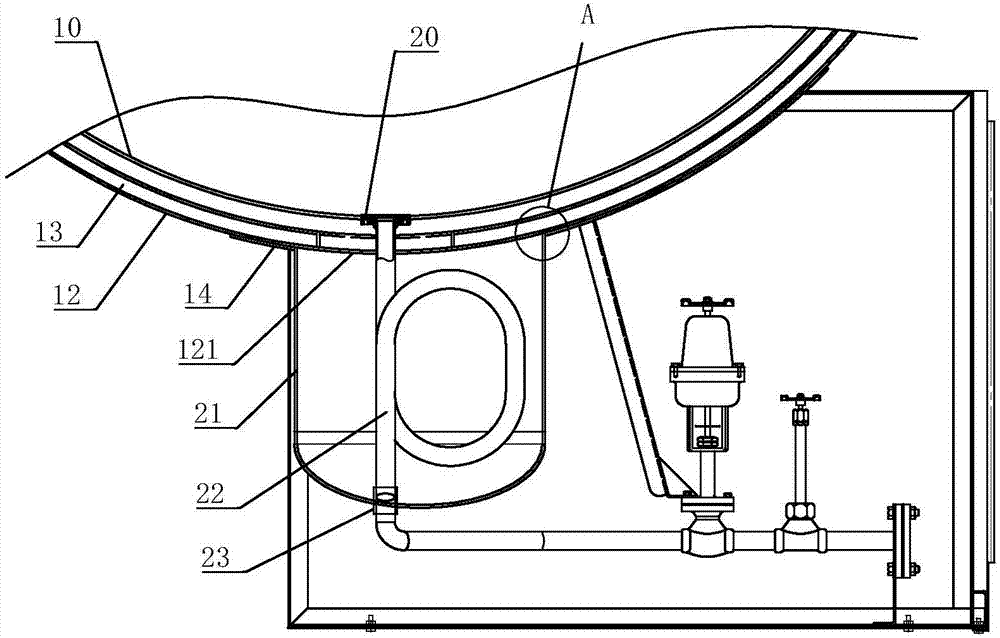

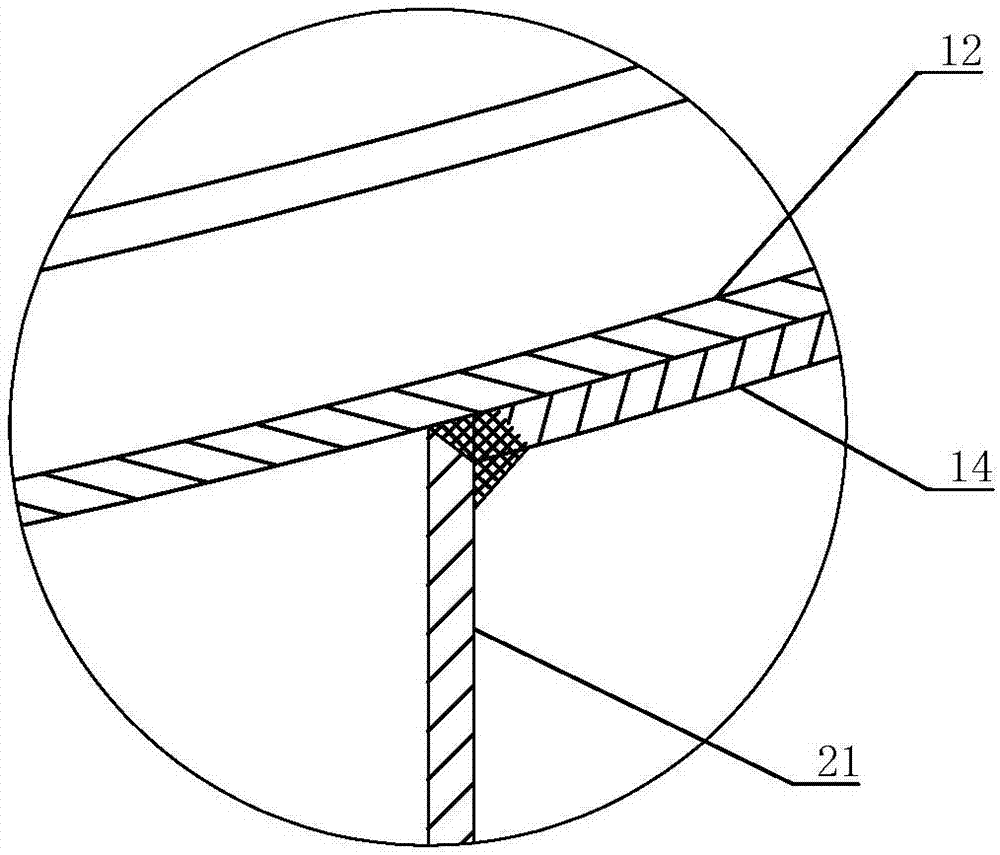

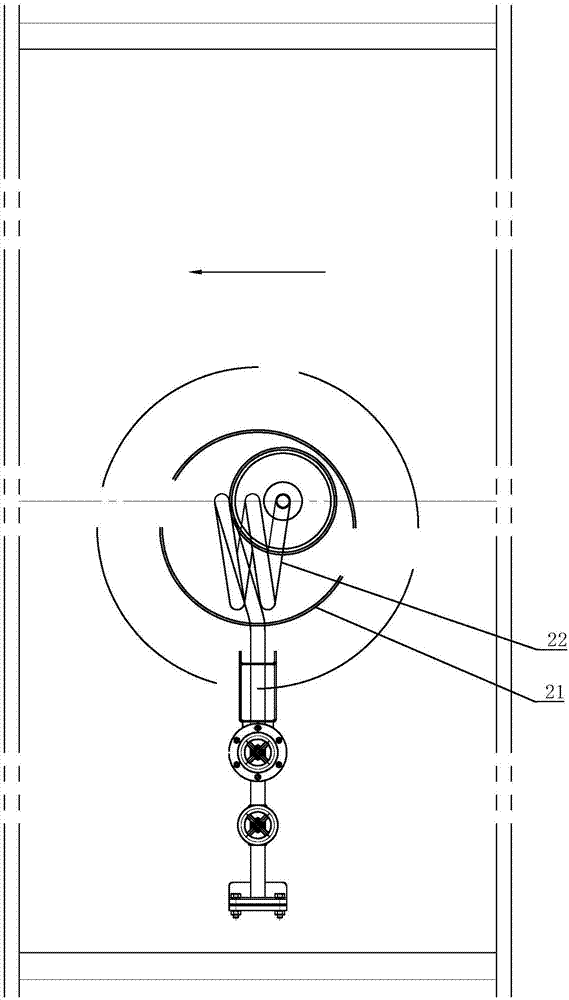

[0032] refer to Figure 1 to Figure 12 , a sandwich lead-out structure for a cryogenic container of the present invention, comprising an inner tank 11, an outer shell 12, a vacuum insulation sleeve 21 and an outlet pipe 22, a vacuum interlayer 13 is formed between the inner tank 11 and the outer shell 12, and the vacuum isolation The sleeve 21 is airtightly connected with the outer shell 12 and communicated with the vacuum interlayer 13. One end of the lead-out pipe 22 is connected to the inner tank 11, and the other end passes through the outer shell 12 to form an overhanging portion, which is set inside the vacuum isolation sleeve 21 There is a curved tube body extending in the direction of cold shrinkage of the liner 11, refer to image 3 with Figure 7 , the direction of the arrow in the figure is the direction of cold shrinkage of the liner 11. Since the present invention arranges the curved pipe body in the vacuum insulation sleeve 21 connected with the vacuum interlay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com