Method and system for automatically controlling combustion-supporting air pressure of heating furnace

A heating furnace and wind pressure technology, which is applied in the combustion method, furnace control device, combustion control and other directions, can solve the problem of inability to automatically control the combustion-supporting air pressure of the heating furnace, and achieves reduction of energy consumption, improvement of adjustment capacity, and reduction of fan energy. consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

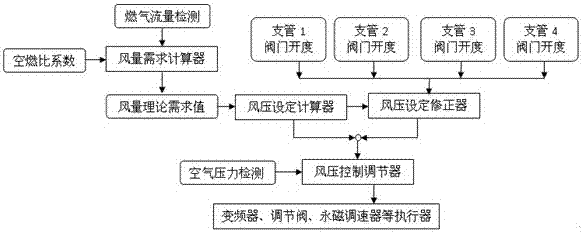

[0022] An automatic control device for combustion-supporting air pressure of a heating furnace, comprising a set of fan flow adjustment device, a set of wind pressure detection device, a set of gas flow detection device, a set of air volume demand, a set of wind pressure setting calculator, a set of wind pressure Pressure setting corrector, a set of air pressure control regulator and four sets of branch pipe valve position feedback devices.

[0023] Its workflow is as follows:

[0024] (1) Install a set of gas flow meters on the gas main pipe, and transmit the flow data Q1 to the air volume demand calculator in real time.

[0025] (2) The air volume demand calculator calculates the current air volume theoretical demand value Q2 according to the current gas main pipe flow Q1, air-to-coal ratio coefficient k, and air excess coefficient n, Q2=n*K*Q1, and outputs this value to the wind pressure setter. At the same time, the demand value of the air volume can also be calculated a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com