Replaceable arc rubber track friction coefficient testing device

A friction coefficient and testing device technology, which is applied in the direction of measuring devices, mechanical devices, instruments, etc., can solve the problem that the noise level of the system cannot be fully improved, the optimal design of the feeding design cannot be realized, and the measurement of the friction coefficient cannot be fully improved. and other issues, to achieve precise overall design, improve feeding efficiency, and reduce noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

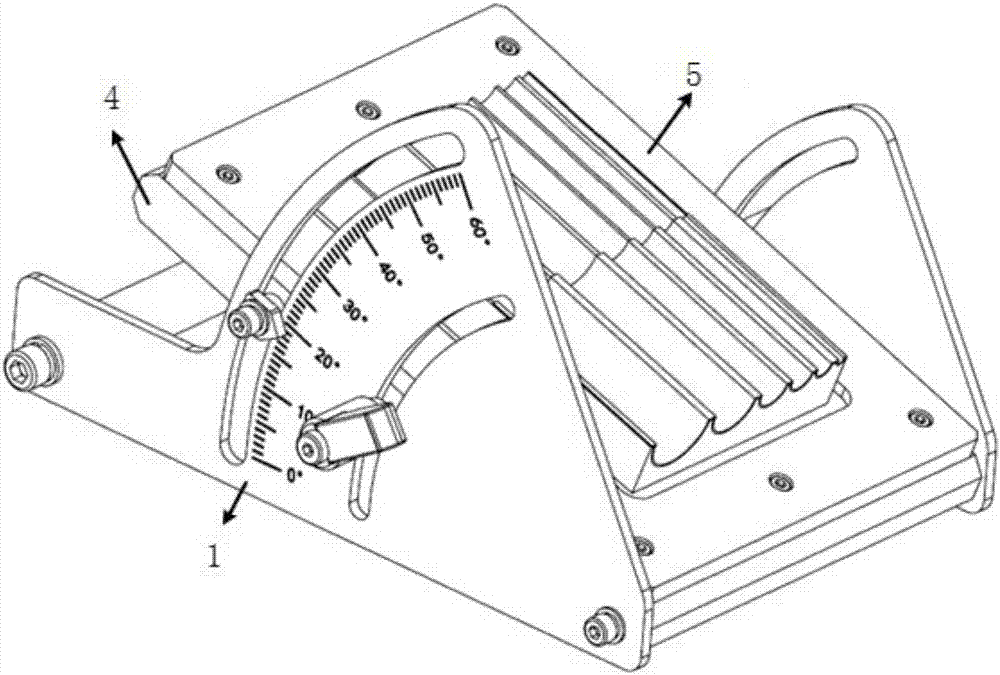

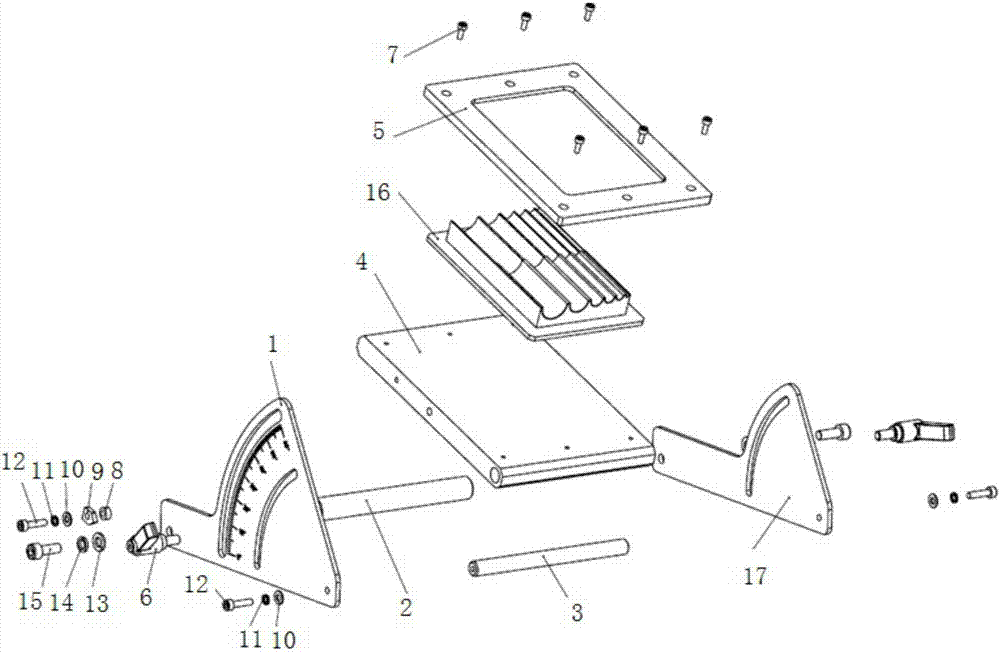

[0023] figure 1 It is a vibrating disc feeding system, which uses the alternating suction between the electromagnet and the armature and the resonance between the system itself, so that the parts in the vibrating disc can climb along the track, and finally enter the end, and pass through the metal frame. After being arranged in an orderly manner, it enters the cutting system. The radius and climbing angle of the climbing track in the tray need to be determined according to the friction coefficient between the part and the tray. The radius of the tray track needs to be determined according to the size of the part itself. At the same time, in order to improve the coefficient of friction, various coatings are usually applied on the surface of the tray. Theoretically, the larger the coefficient of friction, the higher the nail feeding efficiency. Therefore, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com