Transverse wave mode electromagnetic ultrasonic spiral guided wave transducer for detecting interior of pipeline

An electromagnetic ultrasonic and transducer technology, which is applied in the generation of ultrasonic/sonic/infrasonic waves, and the use of vibrating fluids, etc., can solve the problems of single and cannot meet the actual needs of electromagnetic ultrasonic pipeline inspection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

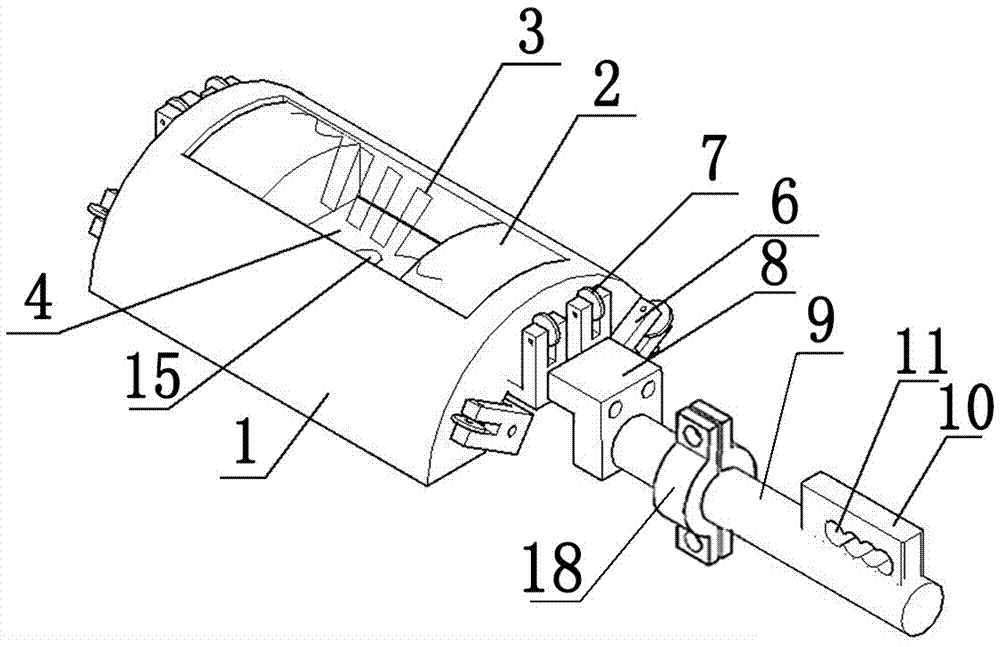

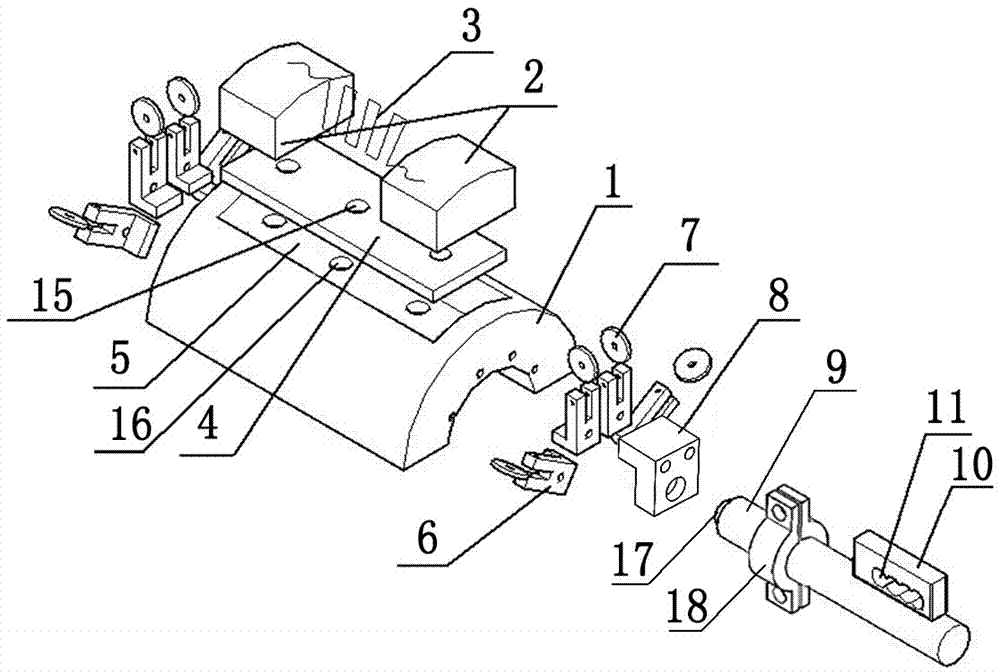

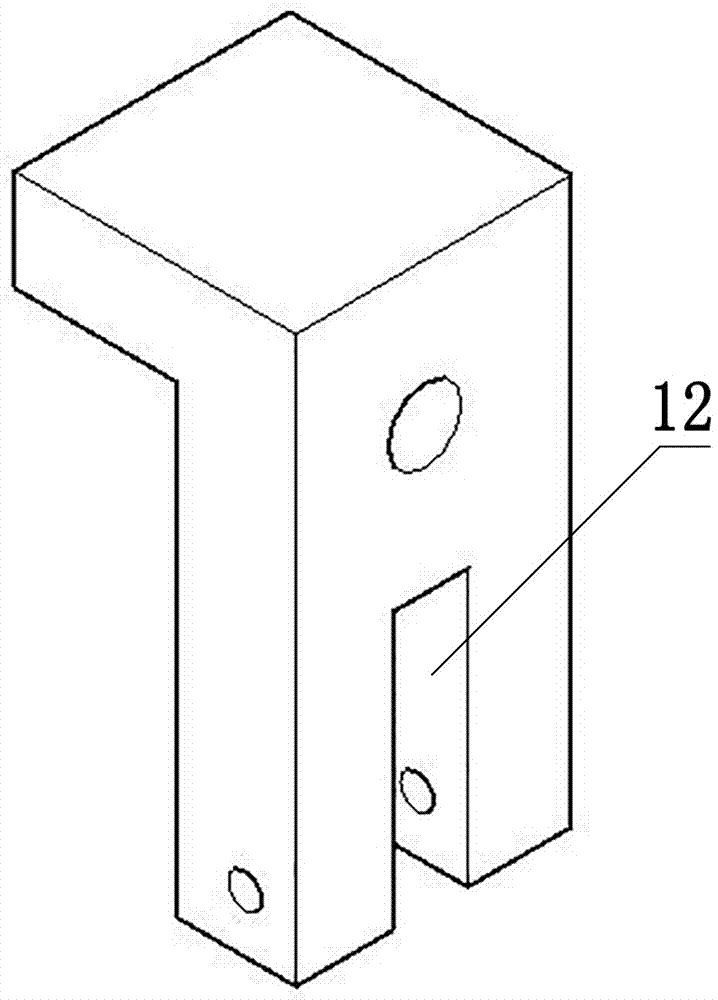

[0030] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 and Figure 7 A helical guided wave transducer for detection in a transverse wave mode electromagnetic ultrasonic pipeline is shown, including a protective shell 1, a holding structure, a walking support structure, a permanent magnet 2, a coil 3, and a yoke 4. The protective shell 1 is arched, and the protective shell 1 is arched. The planes on both sides of the housing 1 are connected with a walking support structure. The walking support structure is composed of a support 6 and a pulley 7. The support 6 is L-shaped. The upper plane at the lower corner is closely attached to the inner arc of the protective housing 1. There is a Square groove 12, pulley 7 is installed in the square groove 12. The supporting member 6 is connected to the planes on both sides of the protective shell 1 , and the pulley 7 is installed on the upper part of the supporting member 6 . The other side of the walking ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com