Cast welding device for lead-acid storage battery and cast welding method of cast welding device

A lead-acid battery, casting and welding technology is applied to the lead-acid battery manufacturing device and its manufacturing field, which can solve the problems of the influence of the busbar mold, explosion, and increase in manufacturing cost, so as to improve processing efficiency, reduce manufacturing cost, and improve service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

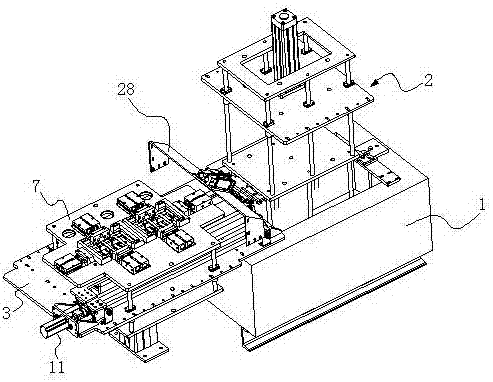

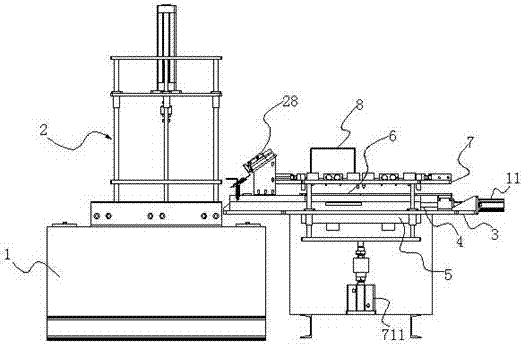

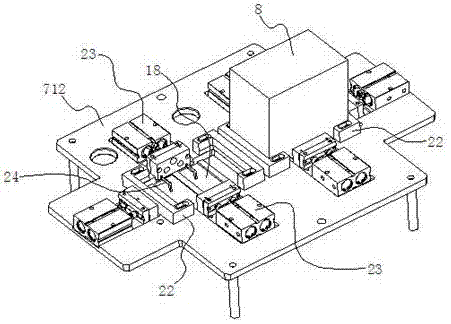

[0038] Example: such as Figure 1 to Figure 5 As shown, a lead-acid battery casting and welding device includes a lifting rail 2 arranged above the lead furnace 1, a workbench 3 arranged on one side of the lead furnace 1, a fixed rail 4 arranged on the workbench 3 and a The water spray mechanism 5 on the workbench 3 and located at the fixed track 4, the bus bar mold 6 is slidably arranged on the fixed track 4 and the lifting track 2 and the bus bar mold 6 can move back and forth between the fixed track 4 and the lifting track 2, On the workbench 3 and above the fixed rail 4, a lifting pallet 7 is provided, and the battery bottom box 8 with multiple pole groups is fixed upside down on the lifting pallet 7; the busbar mold 6 is driven by the lifting rail 2 After immersing in the lead furnace 1 for lead immersion, move the busbar mold 6 to the fixed rail 4, and use the lifting pallet 7 to move down to drive the tabs of multiple pole groups into the lead liquid in the upper cavity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com