Drilling jig with automatic drill hole lubricating function

A technology for automatic lubrication and drilling, which is applied to drilling dies for workpieces, manufacturing tools, metal processing machinery parts, etc. The effect of reduced efficiency and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

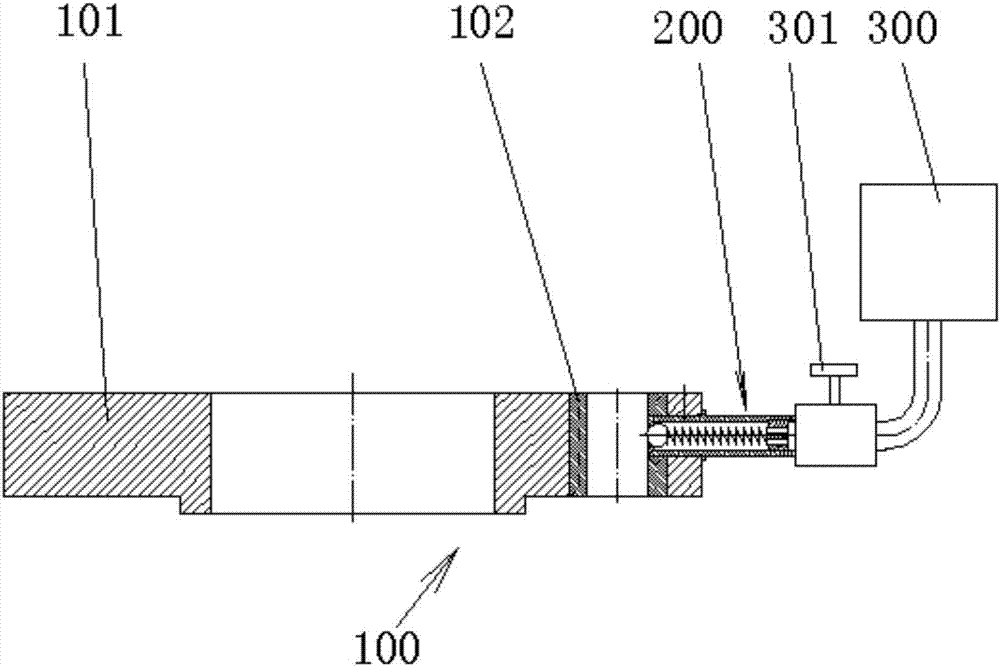

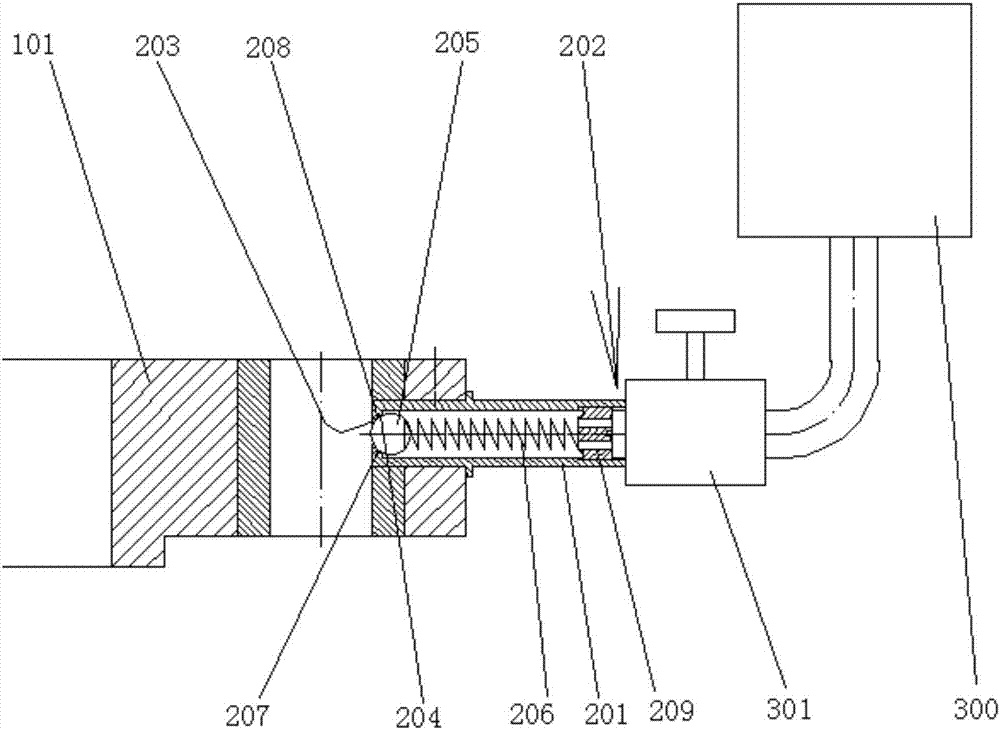

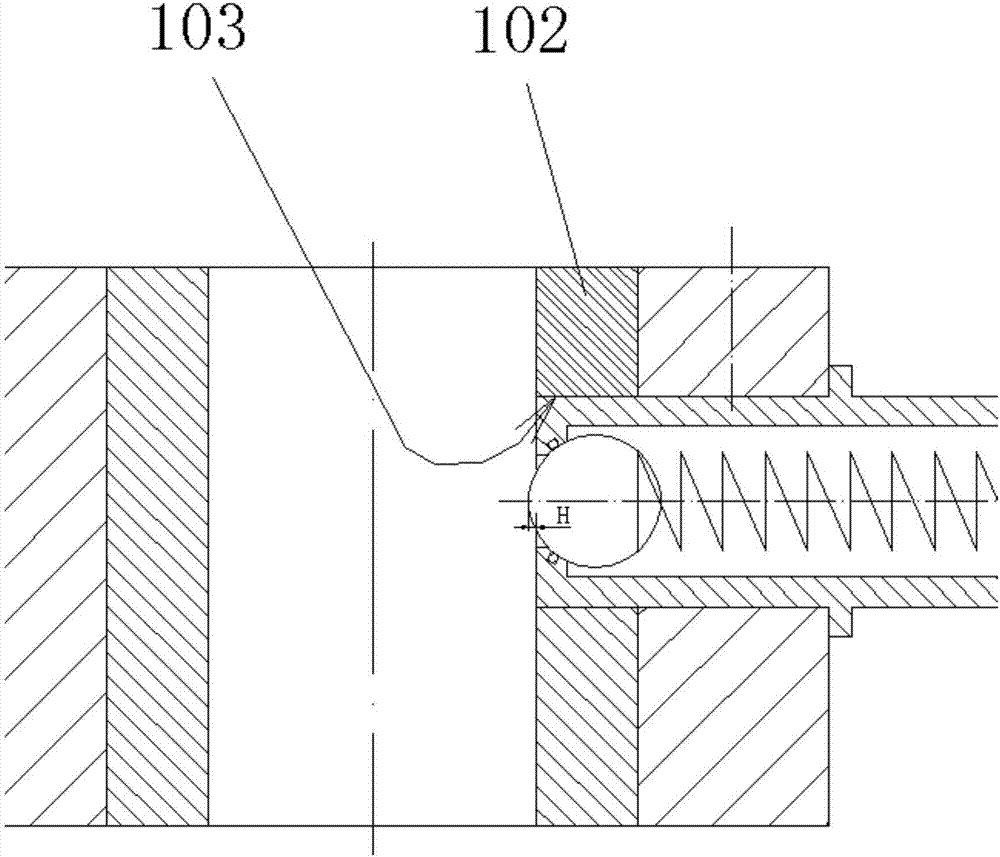

[0037] Such as Figures 1 to 8 It is a drilling template with automatic lubrication function for drilling, including a drilling template assembly 100, a cooling and lubricating assembly 200, and a liquid supply device 300. The drilling template assembly 100 includes a drilling template body 101 and a drill sleeve 102. The drill The sleeve 102 is installed in the template body 101, and the hole wall of the drill sleeve 102 is provided with a transverse through hole 103. The through hole 103 communicates, and the liquid supply device 300 communicates with the cooling and lubricating assembly 200 .

[0038] In this embodiment, the cooling and lubricating ass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com