Special clamp for abrasive material flow finishing machining of variable-cross-section specially-shaped channel structure

A channel structure and special fixture technology, applied in the direction of abrasives, manufacturing tools, metal processing equipment, etc., can solve the problems of lack of tools, inconvenient finishing, etc., and achieve the effect of easy installation and disassembly, simple device, and high surface consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0027] Such as Figure 1-9 shown.

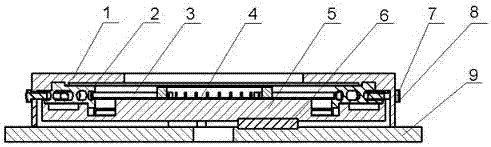

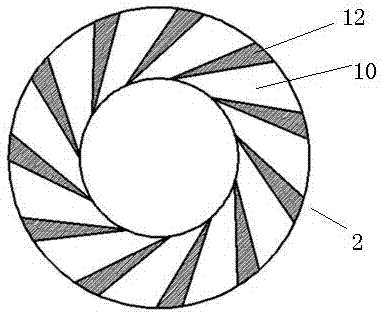

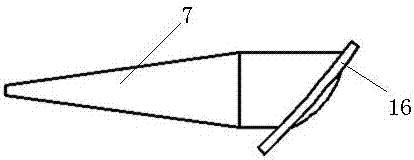

[0028] A special fixture for abrasive flow finishing with a variable cross-section and special-shaped channel structure, which includes a bottom backing plate 9 and a base 5, the bottom backing plate 9 is fixedly connected to the processing machine tool, and a through hole for abrasive materials to enter is provided in the center, and the base 5 passes through the positioning bar 6 Positioned on the bottom backing plate 9, the function of the positioning bar 6 is to realize the circumferential positioning of the base, and in addition to form an abrasive channel between the base 5 and the bottom backing plate 9, and the base 5 is set in the fixture upper cover 1 , the fixture upper cover 1 is fixed on the bottom backing plate 9, the height of the fixture upper cover 1 should ensure the axial positioning of its interna...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com