Crawler climbing type cleaning detection robot with variable framework structure for wind power tower

A frame structure and wind power tower technology, applied in the field of robotics, can solve the problems of wind turbine damage, economic loss, high labor intensity, and low safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

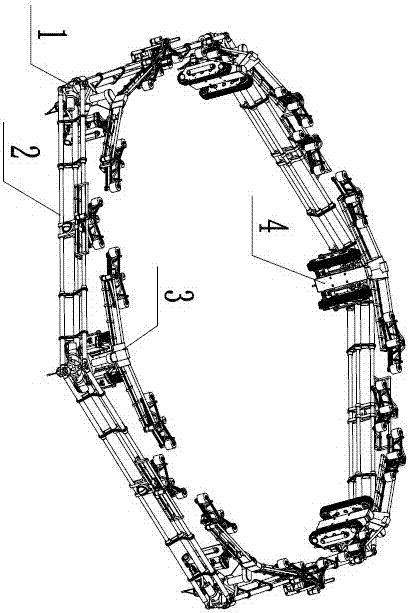

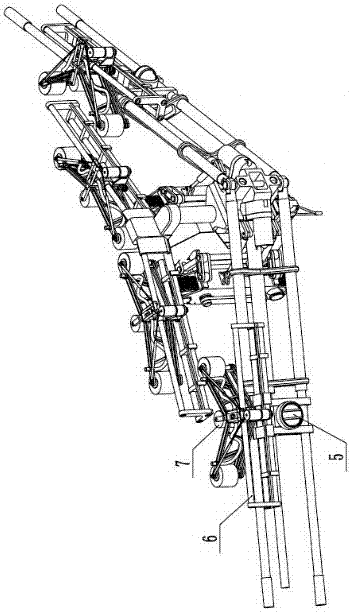

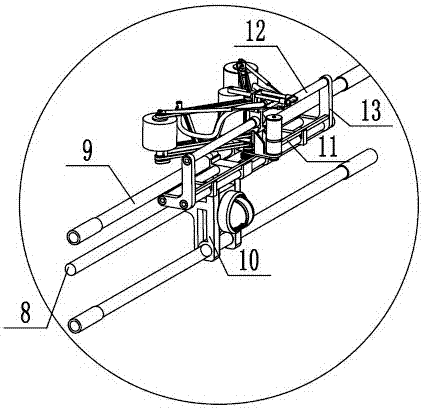

[0049] like figure 1 As shown, a crawler climbing type wind power tower cleaning and testing robot with a variable frame structure includes: a hexagonal frame composed of six sets of variable V-shaped corners 1, connected to variable V-shaped corners 1 and capable of adjusting the size of the frame Push-pull rod mechanism 2, six groups of main cleaning mechanisms 3 installed on the variable V-shaped corner 1 and six groups of tower tube permanent magnet crawler climbing mechanisms 4 installed on the variable V-shaped corner 1. The variable V-shaped mechanism 1 and the push-pull rod mechanism 2 form a variable-sized hexagon to adapt to the change of the diameter of the outer surface of the wind power tower. The hexagonal frame can change its side length to adapt to the wind tower. The diameter changes up and down; the permanent magnet crawler climbing mechanism 4 realizes the contact and compression of the tower through the deformation of the hexagonal frame, and drives the hex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com