A kind of preparation method of high-strength vermicular graphite cast iron plate

A technology of vermicular graphite cast iron and plate, which is applied in the field of preparation of high-strength vermicular graphite iron plate, and achieves the effects of simple process operation, obvious strengthening effect and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] In this embodiment, heat treatment is carried out to the as-cast RuT300 thin plate of 100mm * 28mm * 8mm (length * width * thickness), and the heat treatment process is as follows:

[0028] First, heat a 100mm×28mm×8mm thick as-cast RuT300 sheet to 960°C and keep it warm for 1h.

[0029] Second, take out the sheet sample and air cool to 600°C.

[0030] Thirdly, put the sheet into a furnace preheated to 600°C, and keep it warm at 600°C for 5 minutes.

[0031] Fourth, after the heat preservation is over, take out the sheet and cool it to room temperature in air.

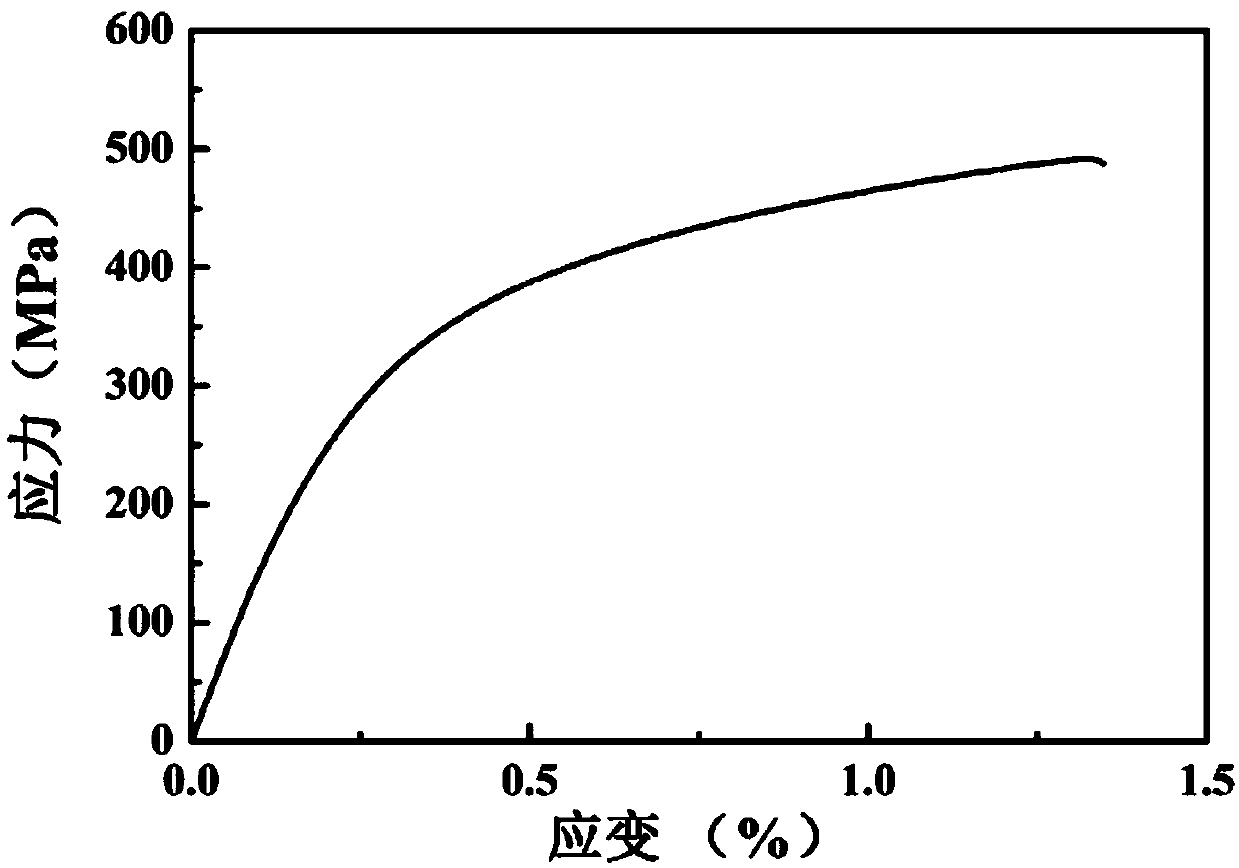

[0032] figure 2 is the engineering stress-strain curve of the isothermal normalizing state RuT300 thin plate of the present invention; the tensile strength of the vermicular graphite cast iron thin plate after adopting the isothermal normalizing heat treatment process of the present invention is 493MPa, and the elongation after fracture is 0.975%.

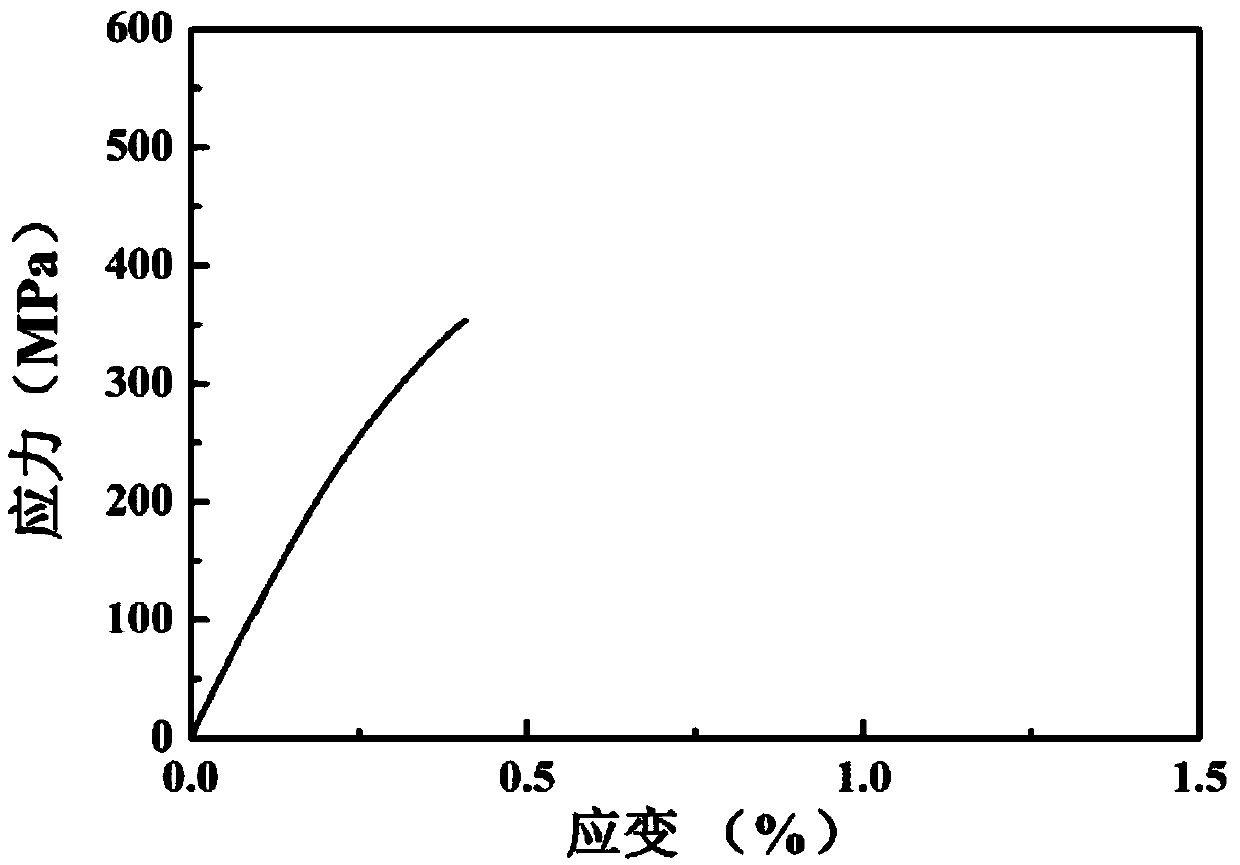

[0033] It can be seen that compared with the traditional no...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com