Knitted jeans twill shaping fabric and preparation process for same

A technology for knitting denim and fabrics, which is applied in knitting, weft knitting, fabric surface trimming, etc., can solve the problems of poor resilience and weak shaping of denim fabrics, and achieve improved wearing performance, good body shaping effect and comfort, The effect of good ventilation and breathing characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

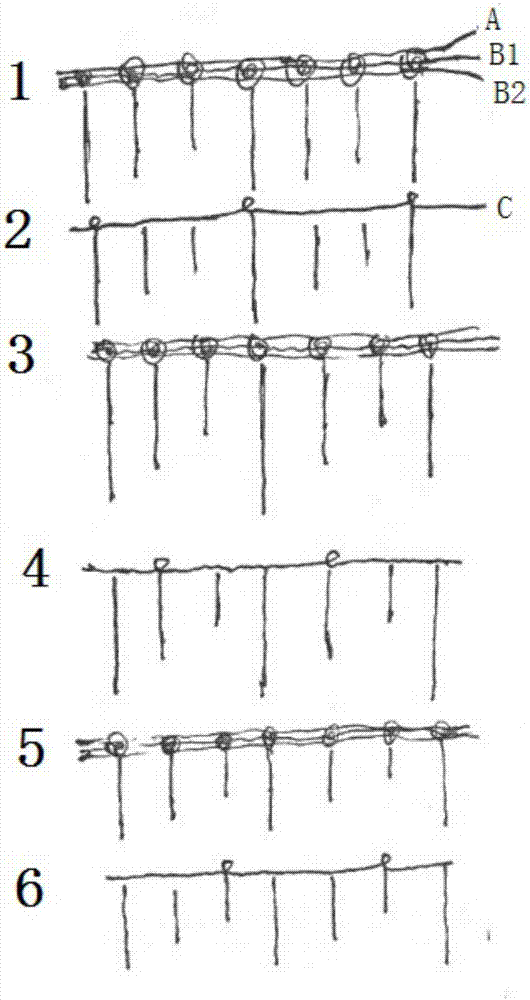

[0028] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0029] The most preferred embodiment of the present invention is a knitted denim twill body shaping fabric. The knitted denim twill body shaping fabric has three layers, which are respectively the surface layer, the middle interlayer and the bottom layer. Polyester fiber and Lycra elastic yarn are used as ground yarn, and Lycra and polyester fiber are in the middle interlayer. At the same time, the plating structure is ground structure. When weaving loops, combed indigo yarn is used as a liner yarn and The ground weave yarns are regularly and periodically shifted and interwoven into loops, floating on the rest of the loops and resting on the bottom layer of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com