Integrated test system for battery system

A comprehensive test and battery system technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problem of high test cost, achieve the effect of reducing test cost, comprehensive test function, and ensuring test test speed and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

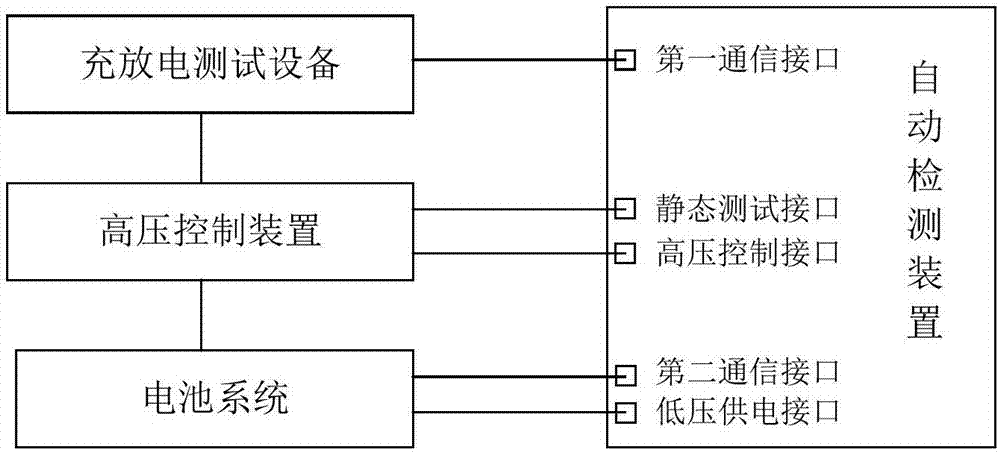

[0026] Such as figure 1 As shown, the comprehensive test system of the present invention includes an automatic detection device, a high-voltage control device and a charge-discharge test device, wherein the high-voltage control device is provided with a static test channel and a dynamic test channel, and the charge-discharge test device is connected to one end of the dynamic test channel. The other end of the test channel is used to connect the battery system.

[0027] The automatic detection device is provided with a static test interface, and is connected to one end of the static test channel through the static test interface, and the other end of the static test channel is used to connect the battery system, and the automatic detection device is connected to the high-voltage control device through the high-voltage control interface for Controlling the on-off of the dynamic test channel and the static test channel, the automatic detection device communicates with the chargin...

Embodiment 2

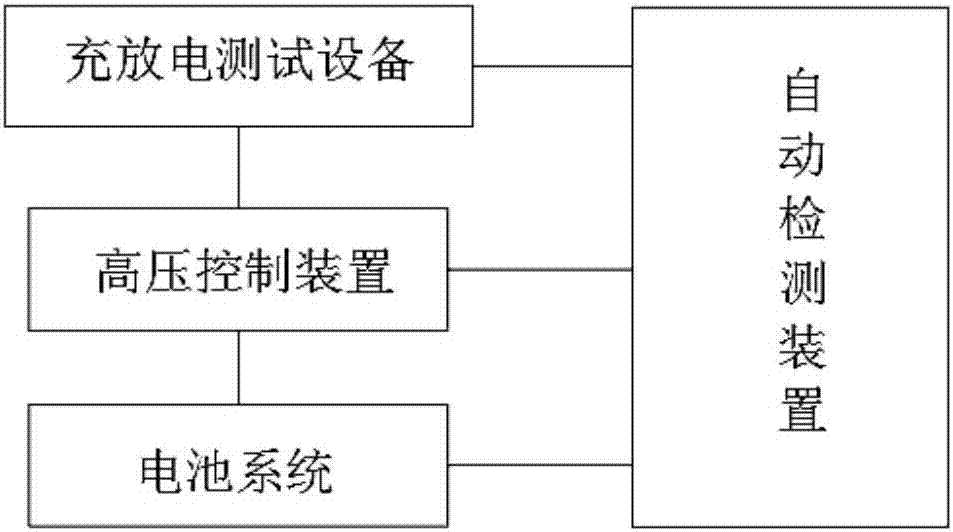

[0044] Such as figure 2 and Figure 6 As shown, the comprehensive test system includes automatic detection device, high voltage control device, battery system and charge and discharge test equipment.

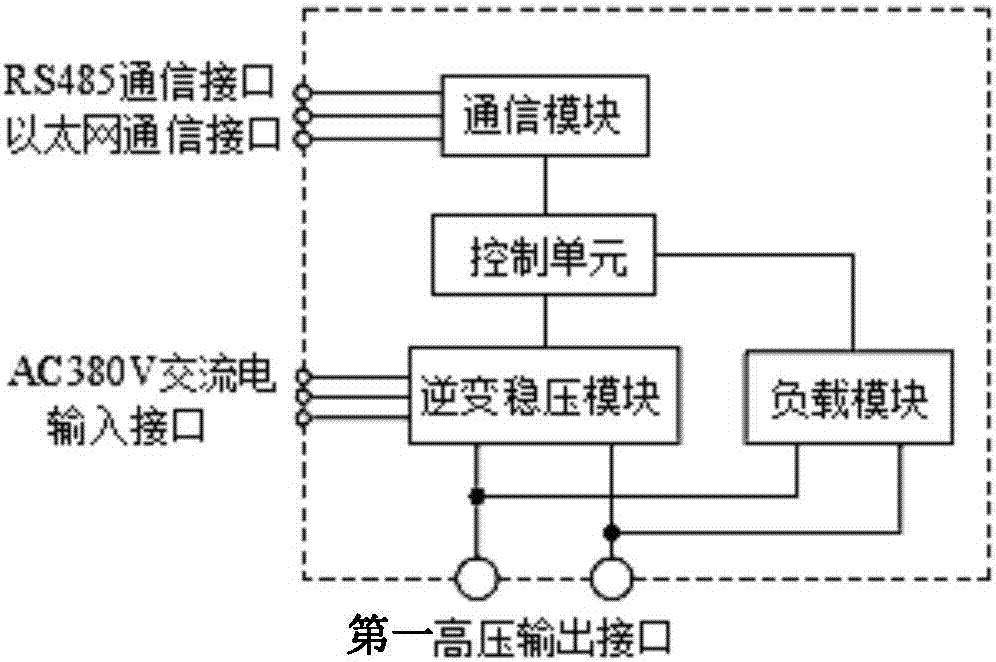

[0045] Among them, the electrical schematic diagram of the charge and discharge test equipment is as follows: image 3 As shown, it includes inverter voltage stabilization module, load module, communication module and charge and discharge control unit. The inverter voltage stabilization module is used to convert the input 380V AC power into a stable high-voltage DC power supply to charge the battery system. The load module is used to discharge the battery system, and the communication module is used to receive external instructions and send them to the charge and discharge control unit. The charge and discharge control unit controls the inverter voltage stabilization module and the load module according to the external instructions received, so as to realize the setting of c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com