Spiral bevel gear tooth surface loading performance optimizing method capable of considering tooth root bending strength

A technology of spiral bevel gear and bending strength, which is applied in the field of tooth surface loading performance optimization, can solve the problems of large amount of calculation, inaccurate calculation of root bending stress, and inapplicability of multiple repeated calculations, so as to ensure calculation accuracy and improve Computational Efficiency Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments. However, it should be understood that the accompanying drawings are provided only for better understanding of the present invention, and they should not be construed as limiting the present invention.

[0064] The method for optimizing the loading performance of the tooth surface of the spiral bevel gear considering the bending strength of the dedendum provided by the present invention comprises the following steps:

[0065] 1) Establish an optimization model for the tooth surface loading of spiral bevel gears considering the bending stress of the dedendum, including the following contents:

[0066] ① Design variables:

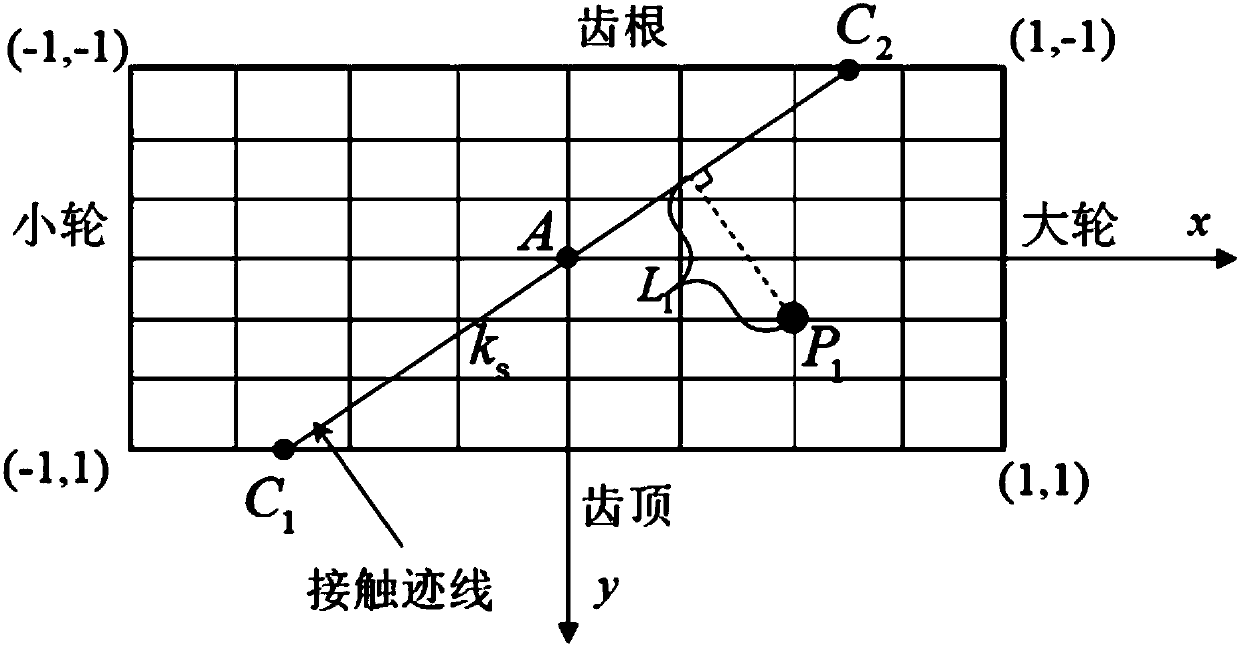

[0067] The design parameters of the tooth surface modification surface of the small wheel of the spiral bevel gear are used as the optimized design variables, and the three design parameters are the pre-control transmission error curve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com