Large workpiece laser cleaning equipment

A technology for laser cleaning and large workpieces, applied in laser welding equipment, metal processing equipment, welding equipment, etc., can solve problems such as laser cleaning of difficult and complex workpiece surfaces, and achieve the effect of high-precision three-dimensional movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The embodiment of the present invention solves the technical problem that it is difficult to perform laser cleaning on the surface of complex workpieces in the prior art by providing a large-scale workpiece laser cleaning equipment, which is suitable for cleaning coverage of large areas and cleaning of complex workpiece surfaces without dead angle, and has the advantages of cleaning Ability to diversify workpiece surfaces.

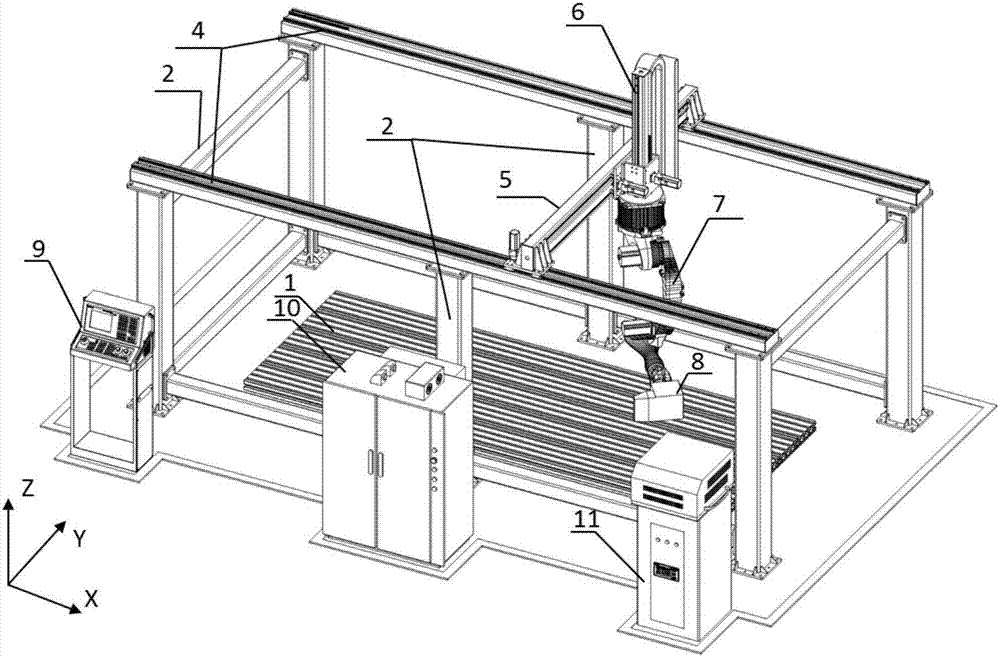

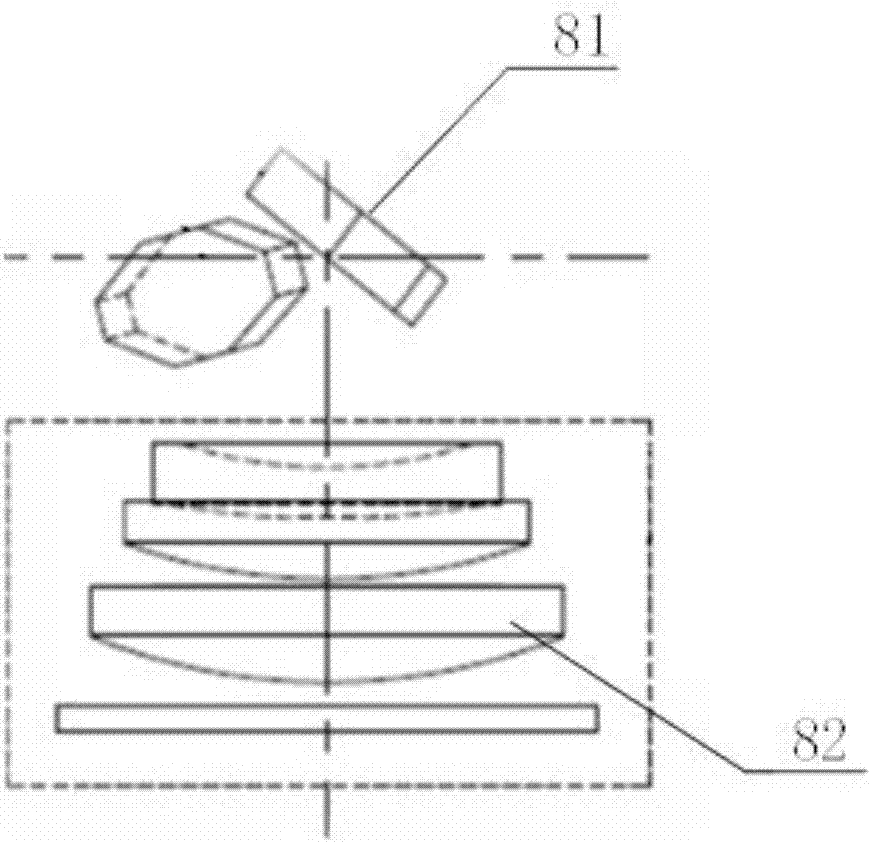

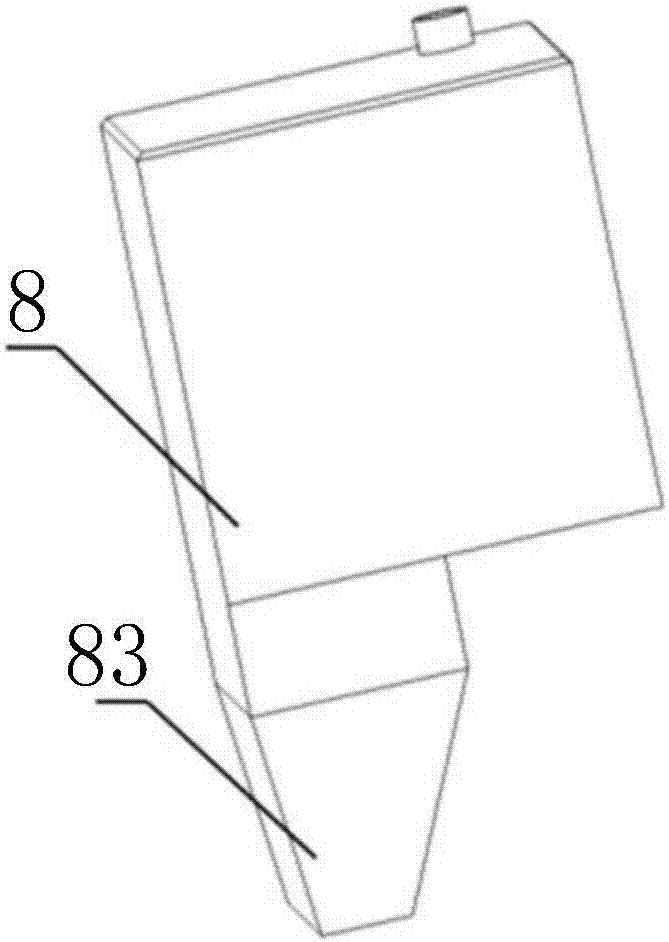

[0035] see figure 1 , the embodiment of the present invention provides a large-scale workpiece laser cleaning equipment, including: a rail beam 4, a beam 5, a lifting column 6, a manipulator 7, a laser scanning unit 8, a fiber laser 10, a first driving device, a second driving device, The third drive device and console 9 .

[0036] The beam 5 is arranged on the track beam 4, and the first drive device drives the beam 5 to move along the track beam 4 in the X-axis direction; the lifting column 6 is arranged on the beam 5, and the second driving devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com