Laser online marking method and device used for packaging material with film coated on surface

A packaging material and laser technology, applied in the field of laser marking, can solve the problems of film layer breakdown, laser beam cannot penetrate the film layer, direct contact with harmful layers, etc., to achieve clear and beautiful effects, shorten operating procedures, and high efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0044] Example 1: Dairy product packaging box marking.

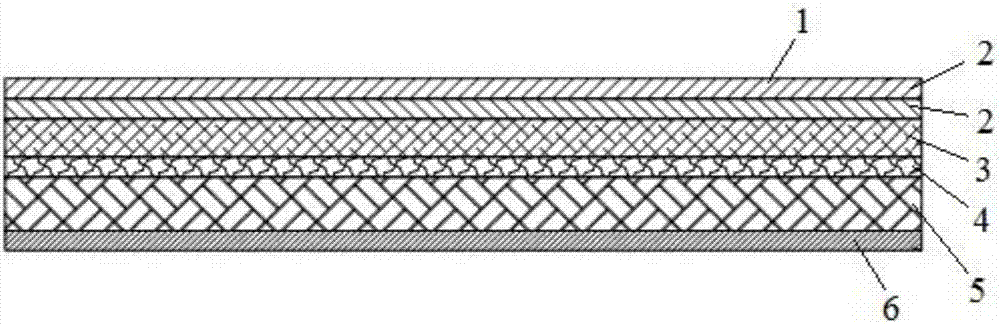

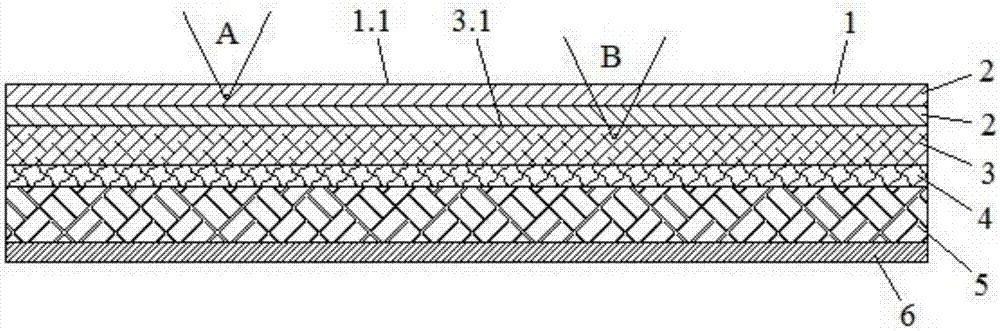

[0045] The dairy product packaging box is composed of 6 layers of PE transparent film, PE transparent film, aluminum foil, PE transparent film, cardboard and PE transparent film from the inside to the outside. This example achieves online marking of the production date and batch number of each packaging box on the two layers of PE transparent film on the surface. The steps are as follows:

[0046] 1) The production date and batch number to be marked are transmitted to the industrial computer through the corresponding interface, and the industrial computer imports it into the software of the marking control system;

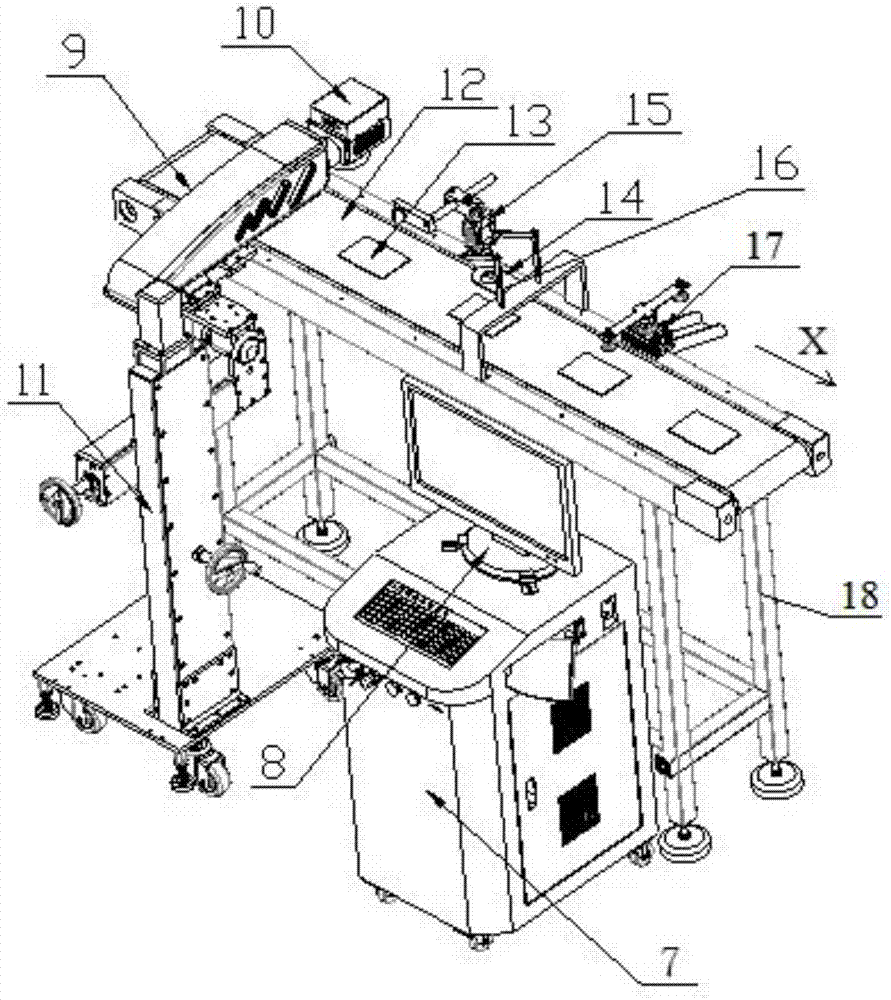

[0047] 2) Manually shake the handwheel on the lifting bracket and roughly adjust the lifting bracket so that the focus position of the laser beam after passing through the laser marking head is roughly on the dairy product packaging box covered with film on the upper surface of the conveying platform;

[004...

example 2

[0053] Example 2: Marking on food packaging lids.

[0054] The food packaging cover is composed of three layers of PET transparent film, paint layer and aluminum plate from the inside to the outside. In this example, the production date and batch number of each food packaging cover can be marked online on the middle paint layer. The steps are as follows:

[0055] 1) The production date and batch number to be marked are transmitted to the industrial computer through the corresponding interface, and the industrial computer imports it into the software of the marking control system;

[0056] 2) Manually shake the handwheel on the lifting bracket and roughly adjust the lifting bracket so that the focal point where the laser beam converges after passing through the laser marking head is roughly on the packaging material coated on the upper surface of the conveying platform;

[0057] 3) The selected laser is an ultraviolet laser with a wavelength of 355nm. Input the corresponding c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com