Processing apparatus for polishing quartz glass cylindrical surface

A technology for quartz glass and processing devices, which is applied in the direction of grinding drive devices, metal processing equipment, grinding/polishing equipment, etc. It can solve the problems of unguaranteed surface accuracy and large wear of polishing machines, and achieve good adhesion and processing The environment is good and the effect of improving polishing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

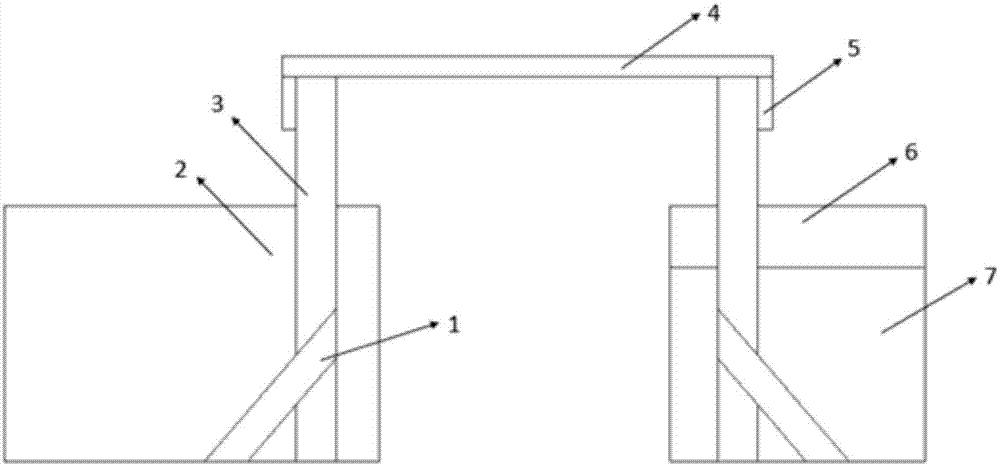

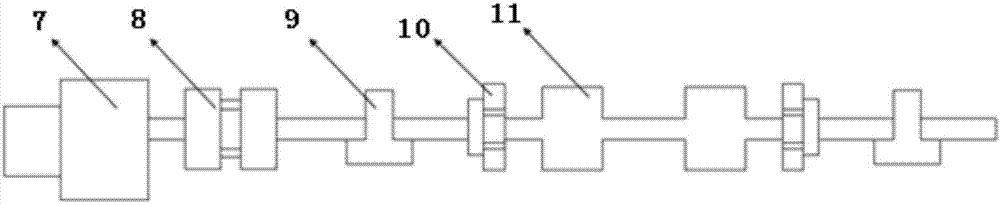

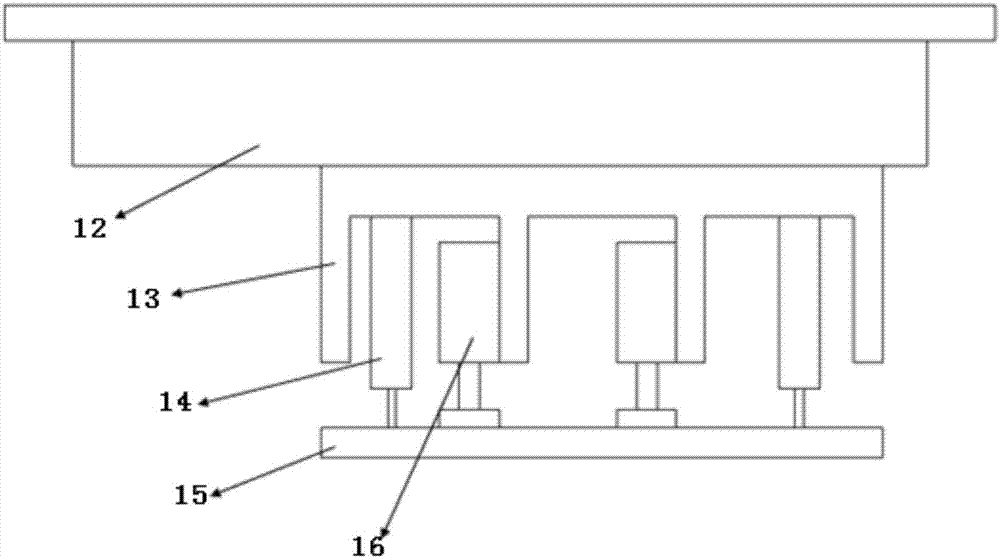

[0027] A processing device for polishing a cylindrical surface of quartz glass, comprising a polishing rotating fixed shaft assembly for fixing the quartz glass 18, a translational polishing disc assembly for polishing the quartz glass 18, and a supporting polishing rotating fixed shaft assembly and a translational polishing disc Components of the supporting gantry, see Figure 1-3 The polished rotating fixed shaft assembly includes a fixed shaft 11 and fixed locking discs 10 arranged at both ends of the fixed shaft 11. The fixed shaft 11 is connected to the rotating motor 7 through a gear box coupling 8, and the supporting gantry is fixedly connected to the marble table, including A pair of left and right columns 3 and an upper cover plate 4 arranged on the top of the column 3, the column 3 is arranged on the support platform 2, and an inclined support plate 1 for reinforcement is provided between the column 3 and the support platform 2, and the column 3 and the upper cover pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com