Defoaming method for desulfurized wastewater concentration tower

The technology of desulfurization wastewater and concentration tower is applied in the field of defoaming of concentration tower, which can solve the problems of slowing down concentration reaction efficiency and long concentration time, and achieves the effect of reducing reaction time and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

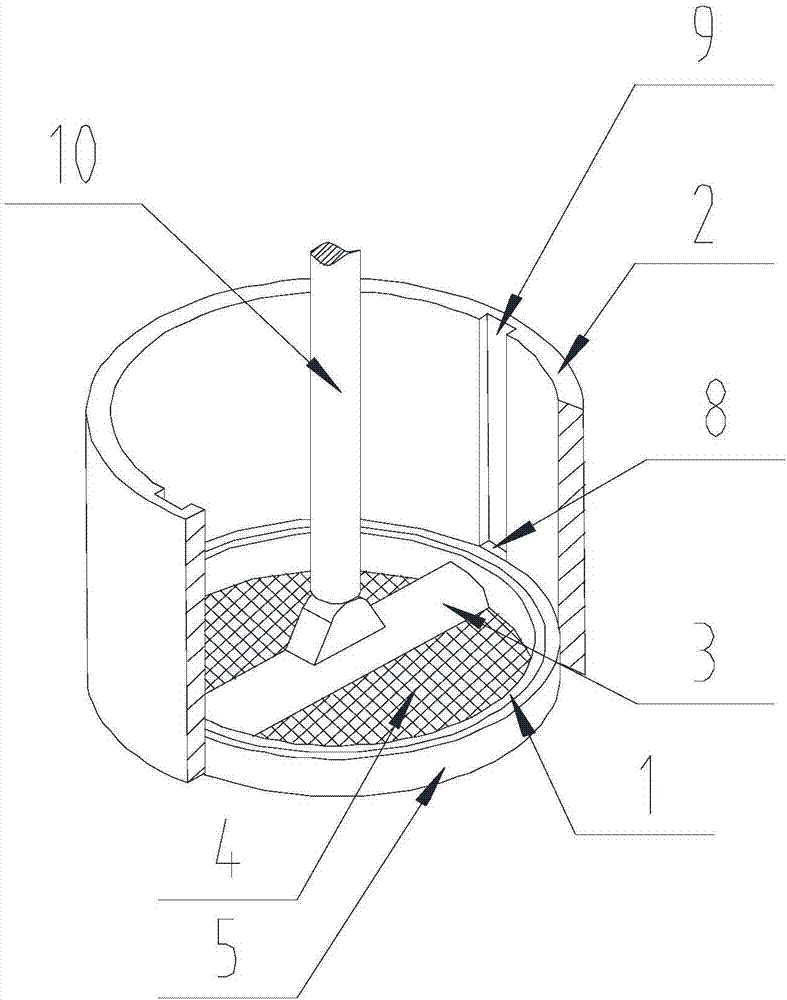

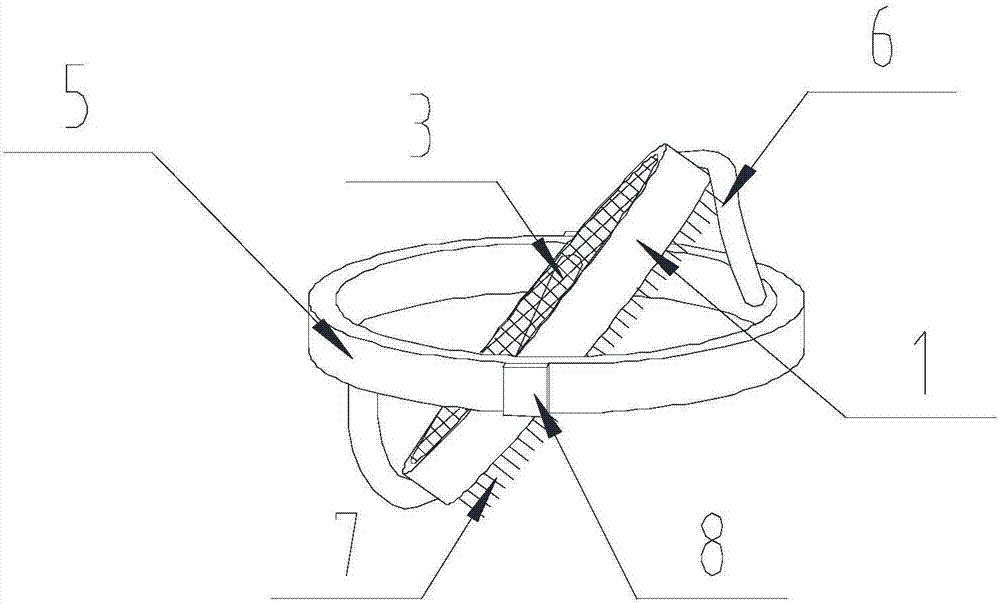

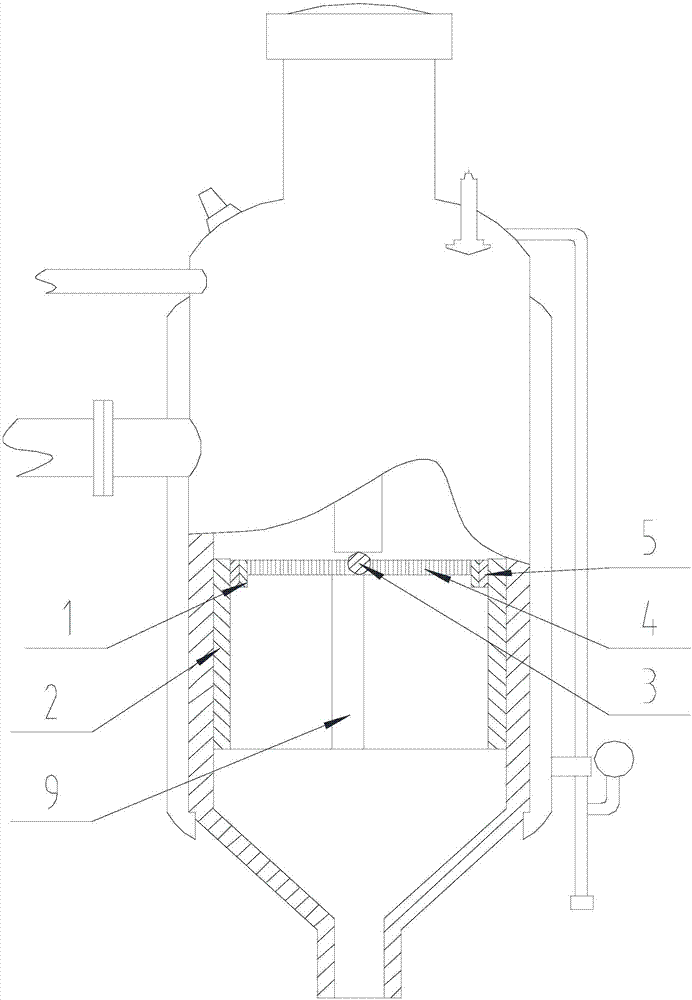

[0029] Such as Figure 1-Figure 3 As shown, the present invention realizes the defoaming method of the desulfurization wastewater concentration tower, including the following steps: Step A installation: first install the installation cylinder 2 inside the concentration tower, and then install the rotating ring 1 with the filter bubble net 4 on the installation cylinder 2 In the center hole of the center hole, both ends of the connecting shaft 3 are connected to the inner wall of the rotating ring 1, and the axis of the connecting shaft 3 passes through the axis of the rotating ring 1, and then one end of the reciprocating drive device 10 is connected to the top of the inner cavity of the concentration tower , the other end of the driving device 10 is connected to the connecting shaft 3;

[0030] Step B Drive: start the driving device, make the rotating ring 1 reciprocate along the axis of the installation cylinder 2, and make the liquid level inside the concentration tower be ...

Embodiment 2

[0034] The present invention is based on embodiment 1, and the present invention is further described.

[0035] Such as Figure 1-Figure 3 As shown, the present invention realizes the defoaming method of the desulfurization wastewater concentration tower, and a moving ring 5 is arranged between the rotating ring 1 and the installation cylinder 2, and the moving ring 5 is sleeved on the outside of the rotating ring 1, and the moving ring 5 Coaxial with the rotating ring 1 , the two ends of the connecting shaft 3 move through the rotating ring 1 and then connect with the moving ring 5 , the rotating ring 1 can rotate around the axis of the connecting shaft 3 .

[0036] The rotating ring 1 can not only remove the foam generated during the reaction of the concentration tower by moving itself, but also can remove the foam generated during the reaction of the concentration tower by rotating itself due to uneven force on both sides of the connecting shaft 3 when it moves up and down....

Embodiment 3

[0040] The present invention is based on embodiment 2, and the present invention is further described.

[0041] Such as Figure 1-Figure 3 As shown, the present invention realizes the defoaming method of the desulfurization wastewater concentration tower. A guide block 8 is arranged on the outer wall of the moving ring 5, and a guide groove 9 is arranged on the inner wall of the installation cylinder 2. The axis of the guide groove 9 is in line with the installation The axes of the cylinder 2 are parallel, and the guide block 8 is located in the guide groove 9 .

[0042] Further, there are several guide blocks 8 and guide grooves 9, and the numbers are consistent with each other. The guide blocks 8 are symmetrically arranged on the moving ring 5 along the axis of the rotating ring 1, and the guide grooves 9 are arranged along the axis of the installation cylinder 2. The center is symmetrically arranged on the installation cylinder 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com