High-efficiency leveling dyeing machine connecting cylinder device and dyeing method thereof

A technology of a vat device and a dye vat, which is applied in the directions of processing textile material equipment configuration, processing textile material containers, etc., can solve the problems of difficulty in guaranteeing the power of two circulating pumps, inability to guarantee the concentration of dyeing liquid, different dyeing time, etc., and achieves simple structure, The effect of easy control and low error rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

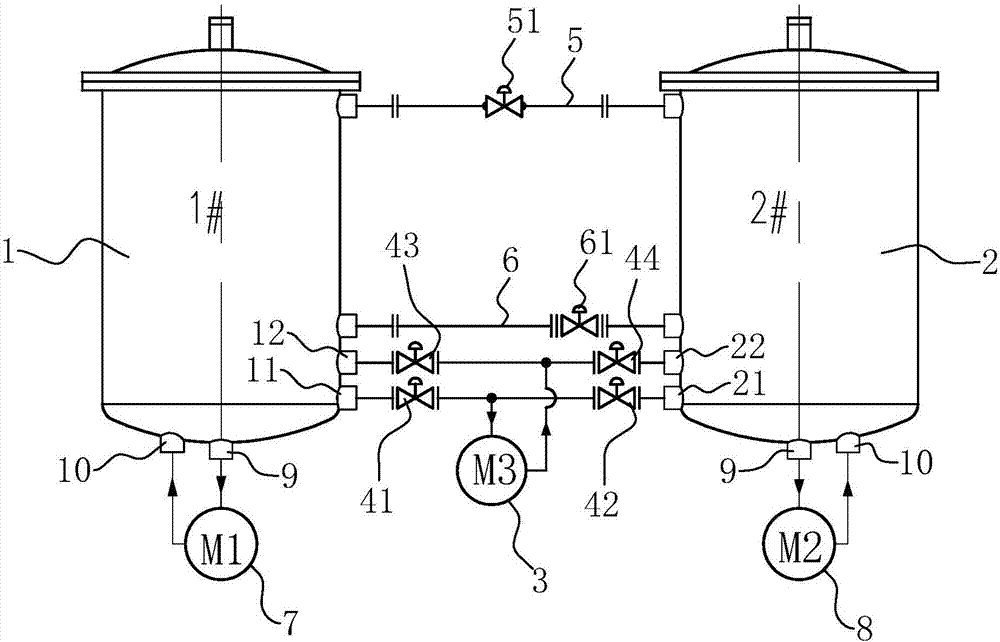

[0047] Embodiment 1: A kind of high-efficiency level dyeing and dyeing machine connecting cylinder device, such as figure 2As shown, it includes a first dyeing vat 1, a second dyeing vat 2, a mixing device and a valve. The mixing device is connected to the first dyeing vat 1 and the second dyeing vat 2 at the same time, and the dyeing solution is extracted from the first dyeing vat 1 and the second dyeing vat 2, After being mixed in the mixing device, it is sent back to the first dyeing vat 1 and the second dyeing vat 2. The valve includes a plurality of regulating valves, which are respectively arranged between the first dyeing vat 1 and the mixing device and the second dyeing vat 2 and the mixing device. The connection relationship between the first dyeing vat 1, the second dyeing vat 2 and the mixing device.

[0048] Both the first dyeing vat 1 and the second dyeing vat 2 are provided with a circulation inlet 10 and a circulation outlet 9, and a first circulation main pump...

Embodiment 2

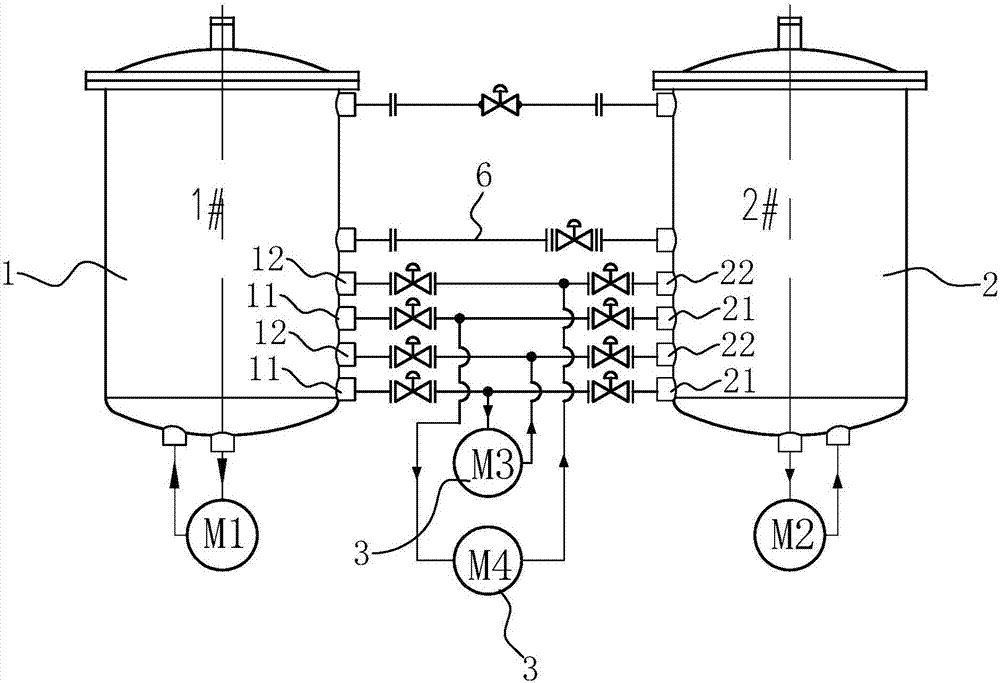

[0061] Embodiment 2: as image 3 As shown, the difference from Example 1 is that the mixing device includes 2 circulation pumps 3, and the first dye vat 1 is provided with two first liquid inlets 12 and two first liquid outlets 11, and the second The dye vat 2 is provided with two second liquid inlets 22 and two second liquid outlets 21 . Wherein, a first liquid inlet and a second liquid outlet 21 are connected as a group to the inlet of a circulation pump 3, and a first liquid inlet 12 and a second liquid inlet 22 are connected as a group to a On the outlet of circulation pump 3.

Embodiment 3

[0062] Embodiment 3: as Figure 4 As shown, the difference from Example 1 is that the number of dyeing vats is four, and a circulation pump 3 is arranged between every two dyeing vats, and the connection mode between the circulation pump 3 and the dyeing vats is the same as that of Example 1.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap