Existing-railway-crossing large-tonnage continuous-beam single-point-pushing rail-passing construction method

A technology with existing railways and construction methods, applied to bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as weak geology at the construction site, large push-up reaction force of bridge piers, and narrow construction site, and achieve simple stress conditions , The construction method is safe and the effect of saving equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

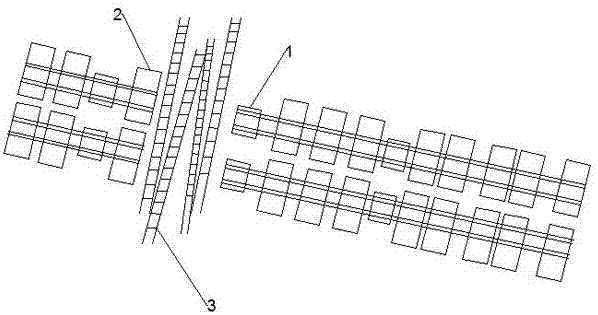

[0033] The following describes the implementation in detail in conjunction with the accompanying drawings.

[0034] A single-point push-through construction method of a large-tonnage continuous beam spanning an existing railway according to the present invention adopts the following steps for construction:

[0035] (1) Foundation construction of main pier 1 and temporary pier 2

[0036] For the weak substratum such as large plain fill and silty clay in the site, pile foundations are used for foundation treatment. A total of 167 temporary piers and 2 pile foundations are set up in the whole bid section, of which 155 are drilled with a diameter of 1.0m Since the pile foundation of temporary pier 2 is relatively close to the existing railway 3, in order to ensure the safety of the existing line, the pile foundation of temporary pier 2 closest to railway 3 adopts 12 Φ1.5m artificially dug piles, and the length of the pile foundation ranges from 16 to 25.2m range.

[0037] (2) Co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com