Variable pitch bearing waste oil collection device and offshore wind turbine adopting same

A technology for collecting waste oil and variable pitch bearings, which is applied in wind turbines, wind power generation, engines, etc., and can solve problems such as difficult collection of waste oil, poor waste oil collection effect, and poor waste oil collection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

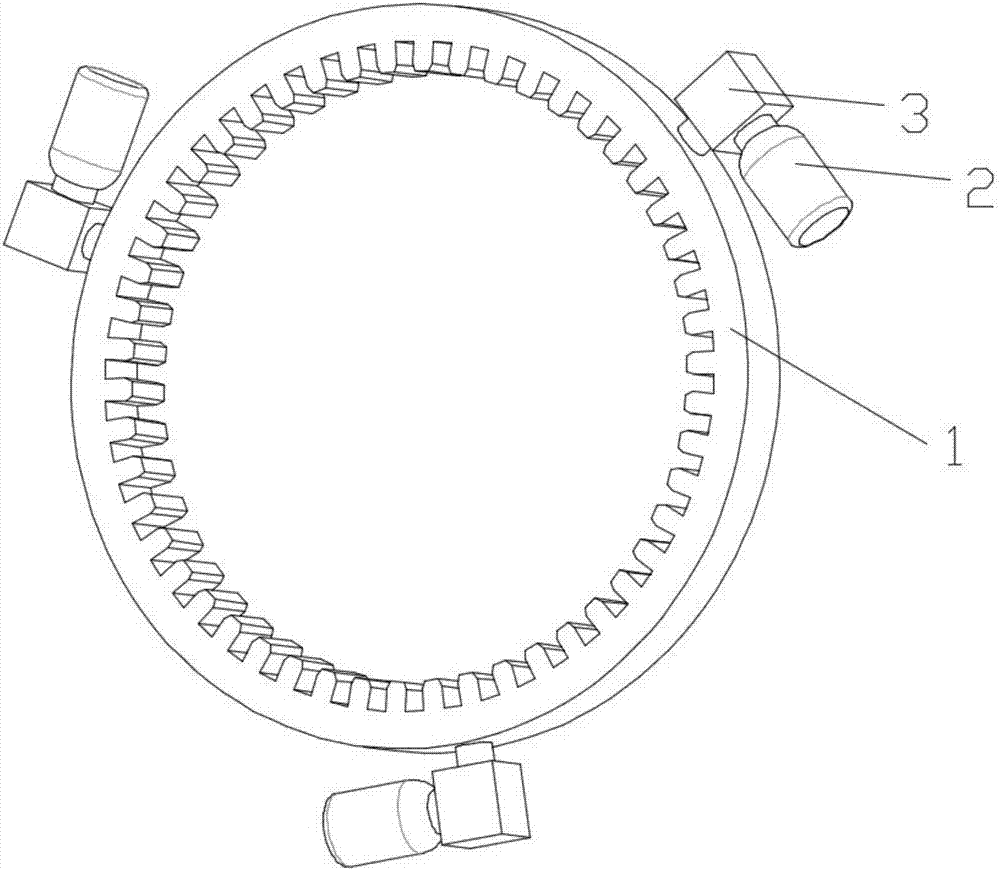

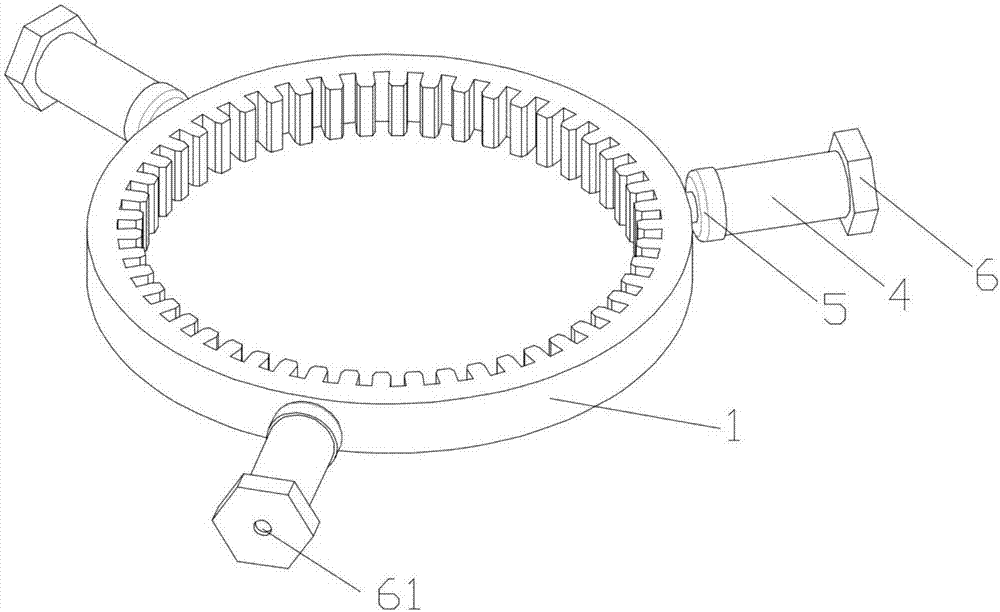

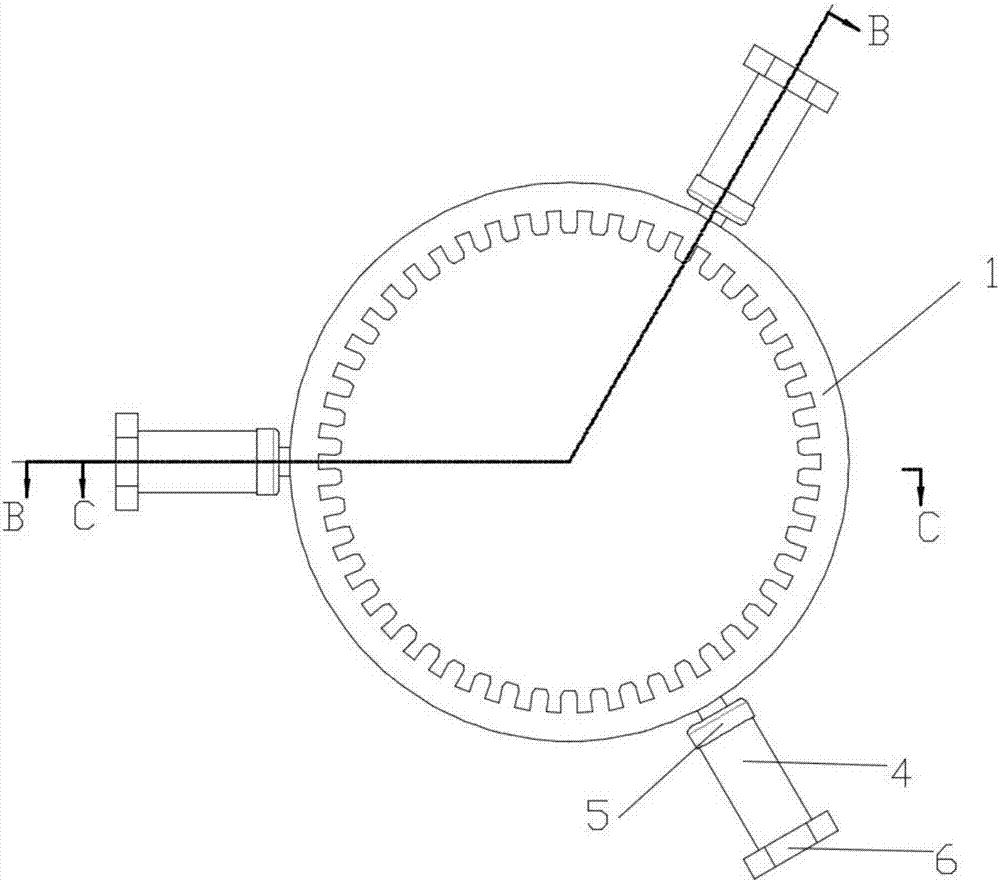

[0025] In order to achieve the purpose of the present invention, as shown in the figure, an embodiment of the present invention is: a pitch bearing waste oil collection device, including a waste oil collection bottle 4 and a connector 5, and the connector 5 is connected to the pitch bearing 1 , the axis of the waste oil collection bottle 4 is collinear with the center of the pitch bearing 1, the inside of the waste oil collection bottle 4 is provided with a piston 7, and one end of the waste oil collection bottle 4 is provided with a connecting portion 42, which is threaded with the connecting head 5 Connect, the other end of the waste oil collection bottle 4 is provided with a back cover 6, the back cover 6 is detachably connected with the waste oil collection bottle 2, and the middle part of the back cover 6 is provided with an air vent 61. The beneficial ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com