Automatic detection equipment for defects of belt-shaped roll material

An automatic detection and roll material technology, which is applied in the direction of optical testing for flaws/defects, can solve the problems of low detection efficiency, high labor intensity, and high probability of missed detection and false detection, so as to achieve no missed detection and false detection, high detection efficiency, The effect of low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

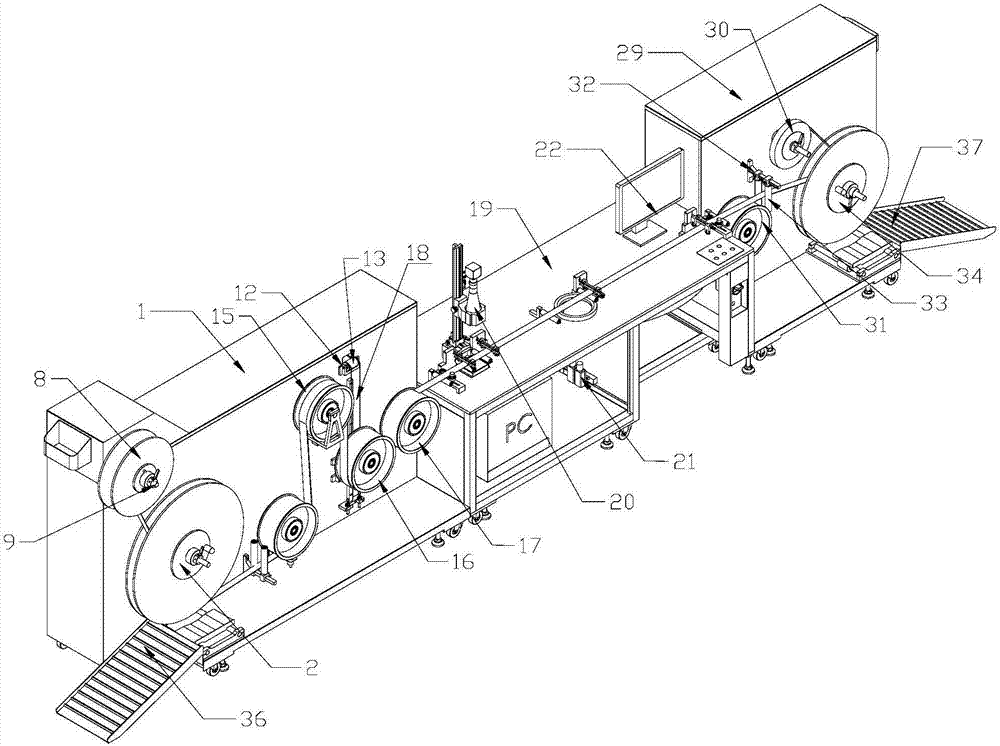

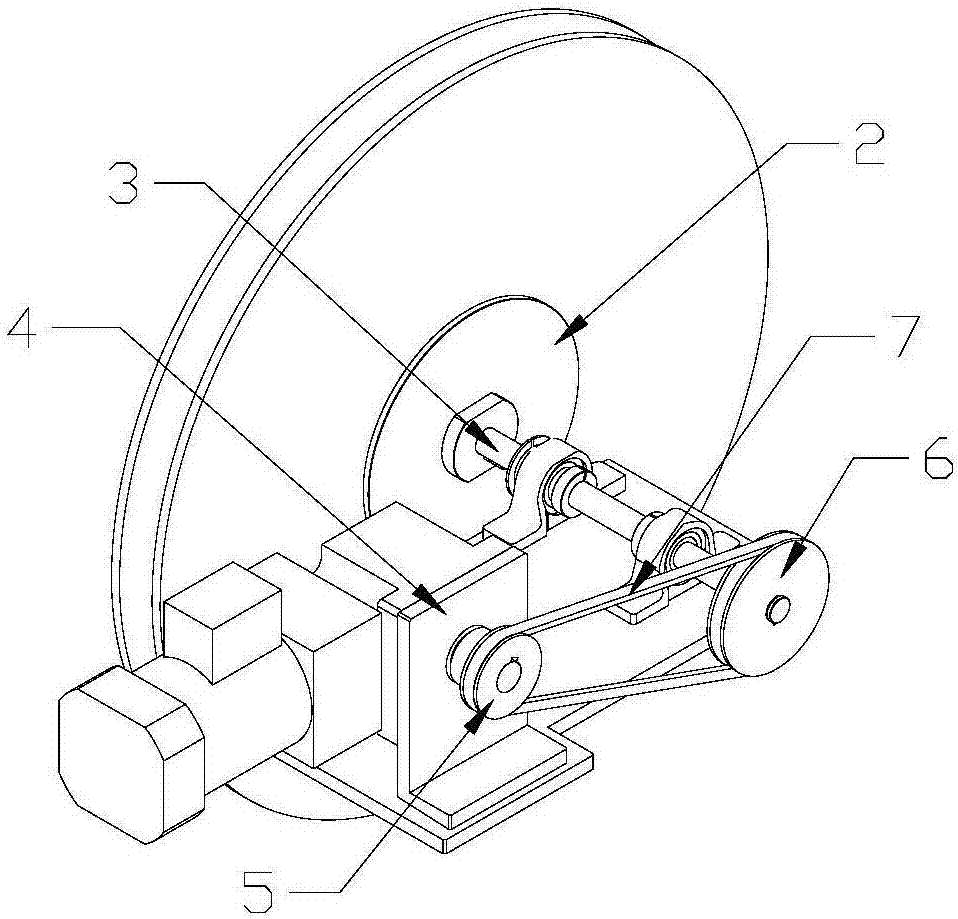

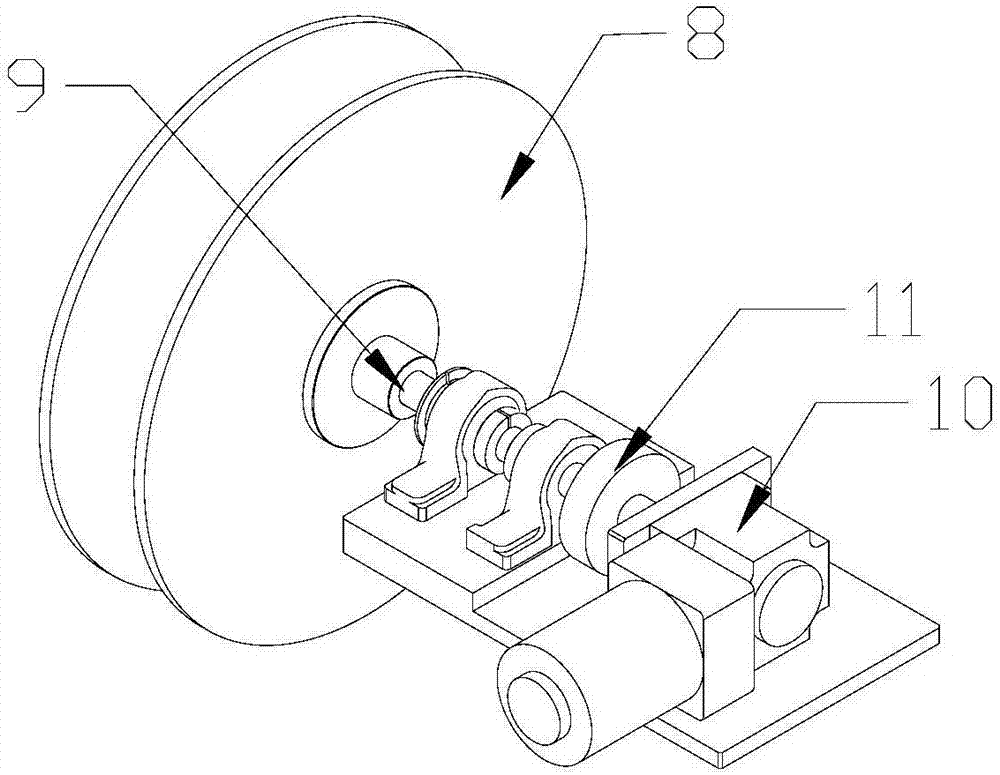

[0024] Embodiment 1: As shown in the figure, a strip-shaped coil defect automatic detection equipment includes a control system, an automatic feeding system, an image shooting detection system and an automatic receiving system arranged in sequence; the control system is respectively connected with the automatic The feeding system, the image shooting detection system and the automatic feeding system are connected. The control system is used to control the cooperative work of the automatic feeding system, the image shooting detection system and the automatic feeding system. The automatic feeding system is used to transfer the strip to be detected. The coil material is transported to the image shooting and inspection system. The image shooting and inspection system is used to take the image of the strip coil material to be inspected and analyze it to obtain the conclusion whether there is a defect and send it to the control system. Ribbon coil winding.

Embodiment 2

[0025] Embodiment 2: As shown in the figure, an automatic detection device for strip-shaped coil defects includes a control system, an automatic discharging system, an image shooting and detection system, and an automatic receiving system arranged in sequence; the control system is respectively connected with the automatic The feeding system, the image shooting detection system and the automatic feeding system are connected. The control system is used to control the cooperative work of the automatic feeding system, the image shooting detection system and the automatic feeding system. The automatic feeding system is used to transfer the strip to be detected. The coil material is transported to the image shooting and inspection system. The image shooting and inspection system is used to take the image of the strip coil material to be inspected and analyze it to obtain the conclusion whether there is a defect and send it to the control system. Ribbon coil winding.

[0026] In thi...

Embodiment 3

[0029] Embodiment 3: As shown in the figure, a strip-shaped coil defect automatic detection equipment includes a control system, an automatic discharging system, an image shooting detection system and an automatic receiving system arranged in sequence; the control system is respectively connected with the automatic The feeding system, the image shooting detection system and the automatic feeding system are connected. The control system is used to control the cooperative work of the automatic feeding system, the image shooting detection system and the automatic feeding system. The automatic feeding system is used to transfer the strip to be detected. The coil material is transported to the image shooting and inspection system. The image shooting and inspection system is used to take the image of the strip coil material to be inspected and analyze it to obtain the conclusion whether there is a defect and send it to the control system. Ribbon coil winding.

[0030] In this embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com