Cumin barbecue powder and making method thereof

A technology of barbecue powder and cumin, which is applied in the field of cumin barbecue powder and its preparation, can solve the problems of unauthentic taste, low specificity, and poor taste of cumin barbecue, and achieve good fullness, strong characteristics, and strong flavor Specific effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

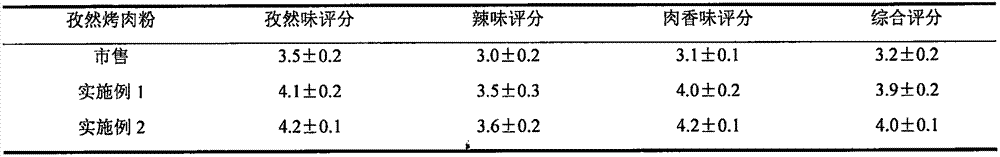

Examples

Embodiment 1

[0025] A preparation method of cumin roasted meat powder is prepared from the following ingredients in parts by weight:

[0026] 16 parts of table salt, 20 parts of monosodium glutamate, 19 parts of white sugar, 0.6 parts of flavored nucleotide disodium (I+G), 0.4 parts of roast beef essential oil, 5 parts of chicken powder, 4 parts of beef powder, hydrolyzed vegetable protein powder (HVP powder ) 4 parts, yeast extract powder 4 parts, garlic powder 5 parts, onion powder 2 parts, chili powder 8 parts, cumin powder 11 parts, anticaking agent 1 part.

[0027] The preparation method of described cumin roasted meat powder, comprises the steps:

[0028] (1) Take salt, monosodium glutamate, and white sugar according to the above-mentioned weight component ratio and pulverize them with a pulverizer, and then pass through a 40-60 mesh sieve to obtain each monomer powder;

[0029] (2) Get roast beef essential oil and the salt powder that step (1) makes, monosodium glutamate powder are...

Embodiment 2

[0034] A preparation method of cumin roasted meat powder is prepared from the following ingredients in parts by weight:

[0035] 18 parts of table salt, 20 parts of monosodium glutamate, 18 parts of white sugar, 0.4 parts of flavored nucleotide disodium (I+G), 0.6 parts of roast beef essential oil, 5 parts of chicken powder, 5 parts of beef powder, hydrolyzed vegetable protein powder (HVP powder ) 4 parts, yeast extract powder 4 parts, garlic powder 5 parts, onion powder 2 parts, chili powder 8 parts, cumin powder 11 parts, anticaking agent 1 part.

[0036] The preparation method of described cumin roasted meat powder, comprises the steps:

[0037] (1) Take salt, monosodium glutamate, and white sugar according to the above-mentioned weight component ratio and pulverize them with a pulverizer, and then pass through a 40-60 mesh sieve to obtain each monomer powder;

[0038] (2) Get roast beef essential oil and the salt powder that step (1) makes, monosodium glutamate powder are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com