Efficient blasting relieved drainage method for covered roadway on low-permeability high-gas coal bed

A technology of gas drainage and low gas permeability, which is applied in gas discharge, mining fluid, mining equipment, etc., can solve the problems of poor effect of anti-reflection and pressure relief, small blasting disturbance, small impact range of fracture network, etc. Large length and reach, easy to achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is described further below:

[0028] A method for efficiently depressurizing gas in a sheltered roadway in a low-permeability and high-gas coal seam, comprising the following steps:

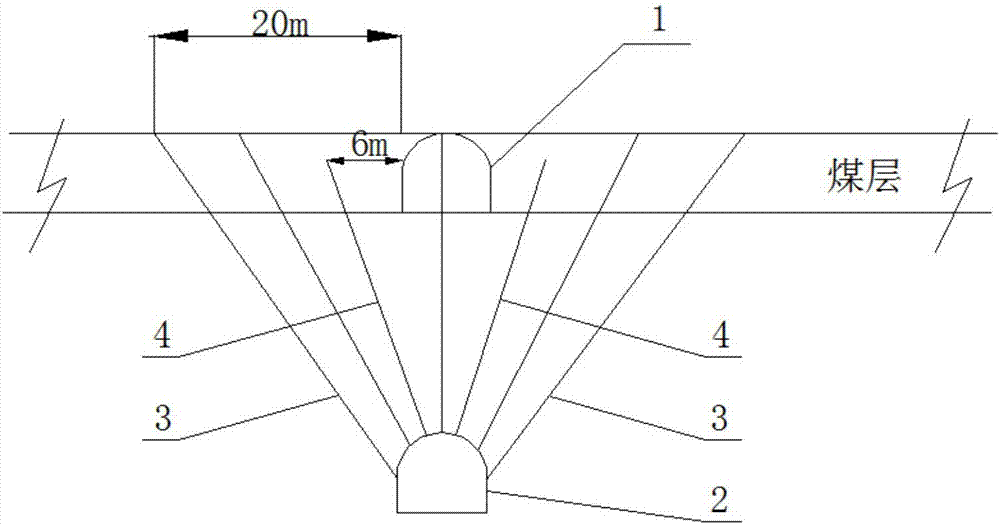

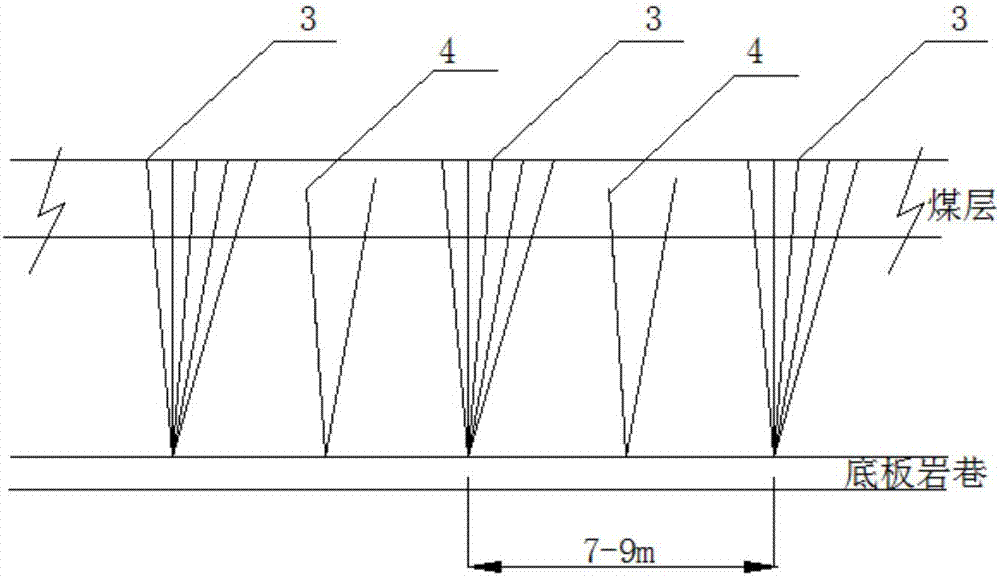

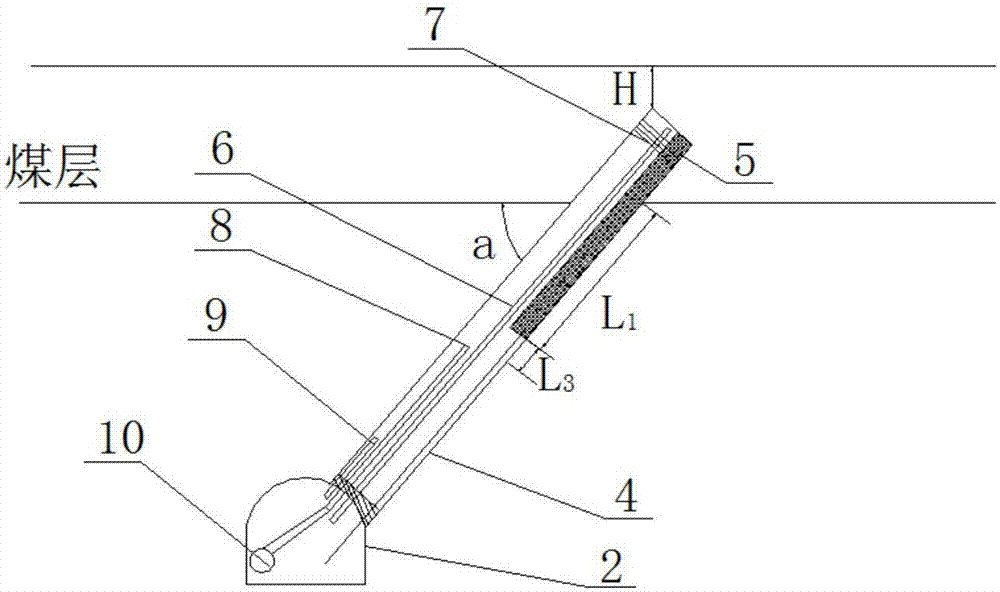

[0029] 1. Construct a bottom slate roadway on the floor of the coal seam of the protected roadway, the bottom slate roadway and the protected roadway are parallel to each other, and construct a group of gas drainage holes 5-7 perpendicular to the protected roadway every 7-9m in the bottom slate roadway The position of the final hole of each group of drainage holes is within the range of 20m on both sides of the protected roadway. When each gas drainage hole penetrates the roof of the coal seam, the drilling is stopped, and the distance between the final holes is 6-9m. After the construction of each group of extraction holes is completed, the lower extraction pipes are grouted and sealed, and then the stubble extraction is performed.

[0030] 2. Construct 2 blast hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com