Method of roller printing of high crispness cookie

The technology of a cookie and a production method, which is applied in the field of food processing, can solve the problems of easy dropping of cake residue and the like, and achieve the effects of unique flavor, convenient operation and simple production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

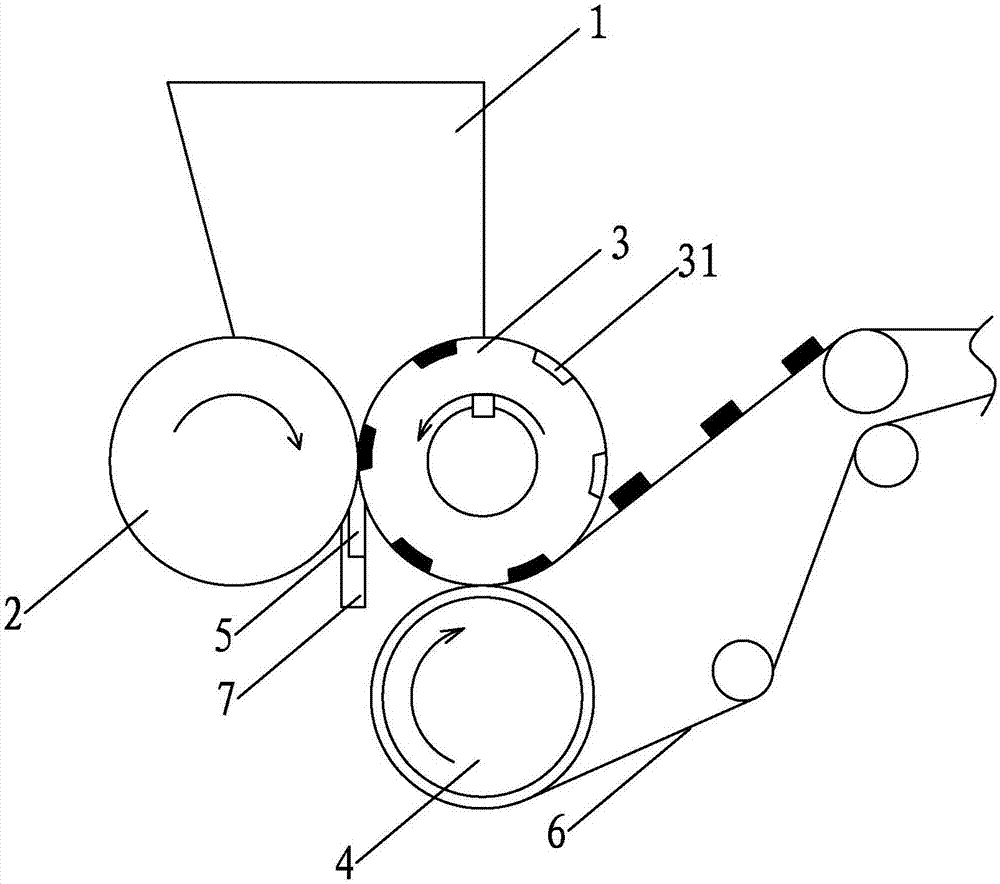

Image

Examples

Embodiment

[0027] 1. The production of cookies

[0028] A method for making high-crisp cookies by roll printing, comprising the following steps:

[0029] (1) Preparation of special syrup:

[0030] ① Weigh 15 parts by weight of super-grade white sugar and 3 parts by weight of water, mix them in a special pot and stir evenly, use a gas stove to heat and boil until the super-grade white sugar is completely melted, then spray 0.2 parts by weight of water to scrub the side of the special pot, Melt the extra-grade white sugar on the side of the pot;

[0031] ②Then boil on high heat to 140°C, then turn to medium heat and boil until 160°C off the fire, the time from ignition to off the fire is controlled at 35 minutes, of which the boiling time is 10 minutes, and the remaining time is the boiling time, the boiling time is short , fast sand return, moderate cooking time, not easy to return sand;

[0032] ③Take the special pot from the stove and let it cool naturally for 2 minutes, then add a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com