Flare gas washing device

A water washing device and torch gas technology, which is applied in the separation of dispersed particles, chemical instruments and methods, and the use of liquid separation agents, etc., can solve the problems of difficult cleaning of filter elements, inconvenient operation and maintenance, etc., and achieve simple process flow and equipment configuration. , Improve safety and reliability, save equipment investment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

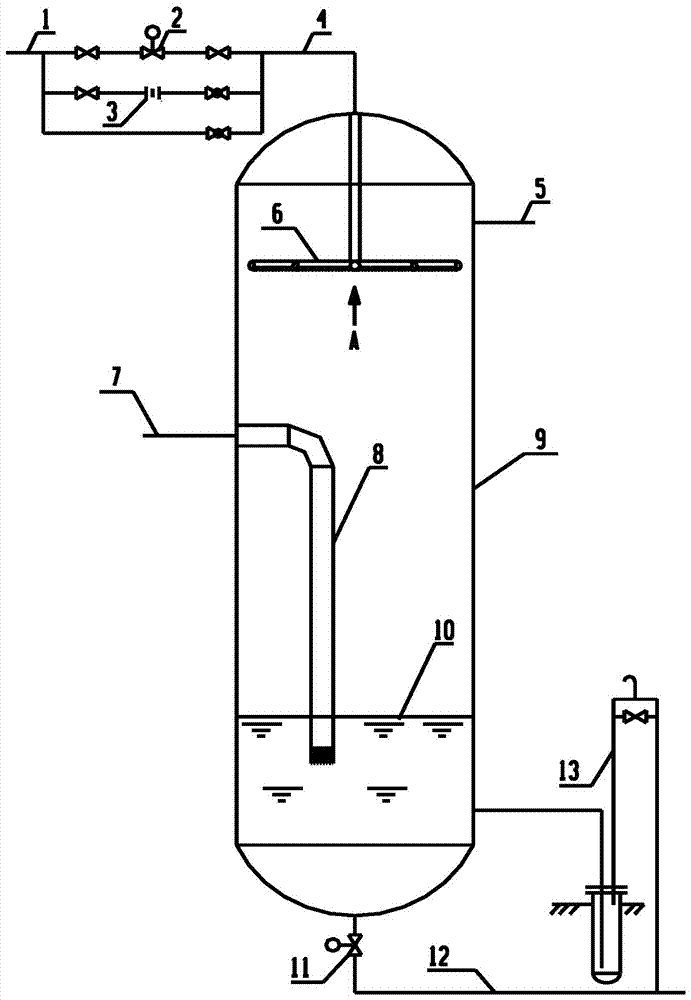

[0025] Such as figure 1 As shown, the torch gas water washing device provided by the present invention mainly consists of a water supply system, a water washing system and an overflow system.

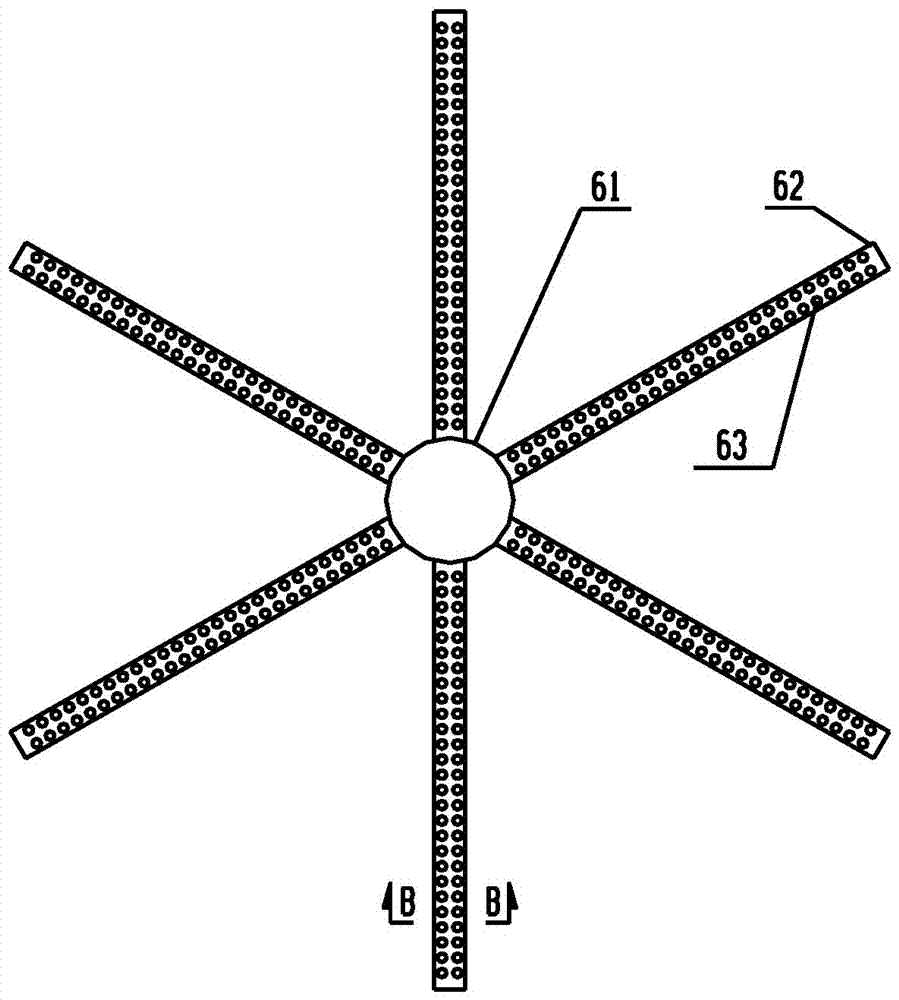

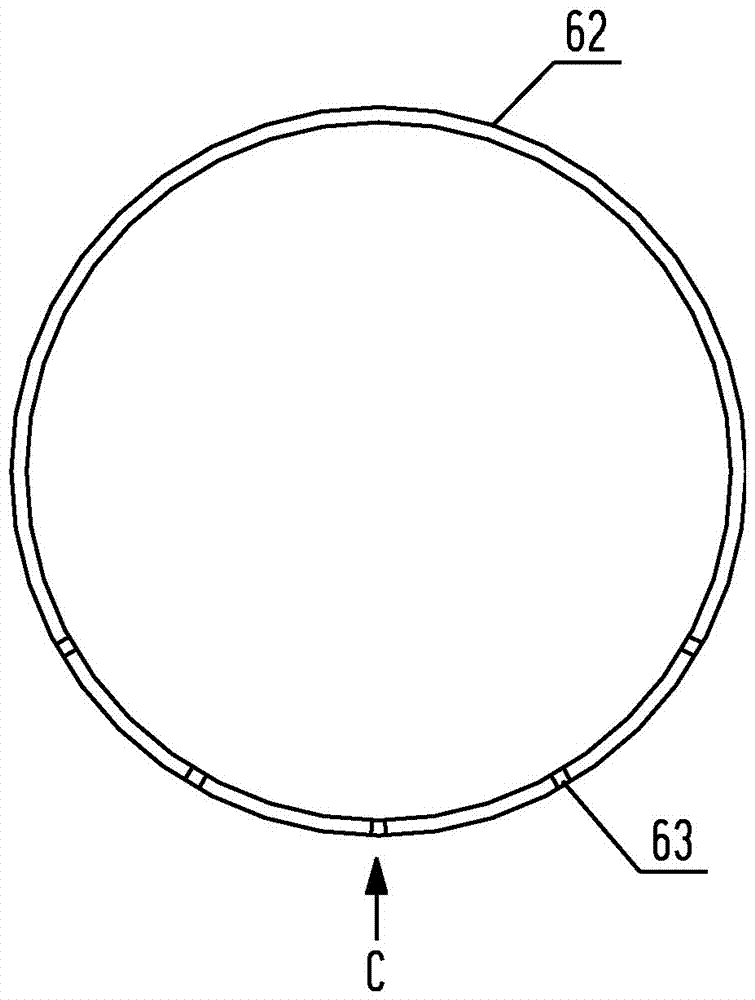

[0026] The water supply system is mainly composed of water inlet pipe 1, bypass flow limiting orifice 3, water inlet automatic control valve 2 and water outlet pipe 4, bypass flow limiting orifice 3 and water inlet automatic control valve 2 are connected in parallel, and one end of the parallel connection is connected to water inlet pipe 1, The other end is connected to the outlet pipe 4, the main pipe 61 of the outlet pipe 4 and the spray distributor 6 (see figure 2 ) are connected at the upper end.

[0027] The water washing system is mainly composed of spray distributor 6, torch gas standpipe 8, vertical water washing tank 9 and sealed water body 10, and spray distributor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com