Edge grinding device for mechanical tool

A technology for sharpening and cutting tools, which is applied to grinding drive devices, grinding/polishing safety devices, tools used in lathes, etc. Safety and reliability, avoid tool shattering, good general performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

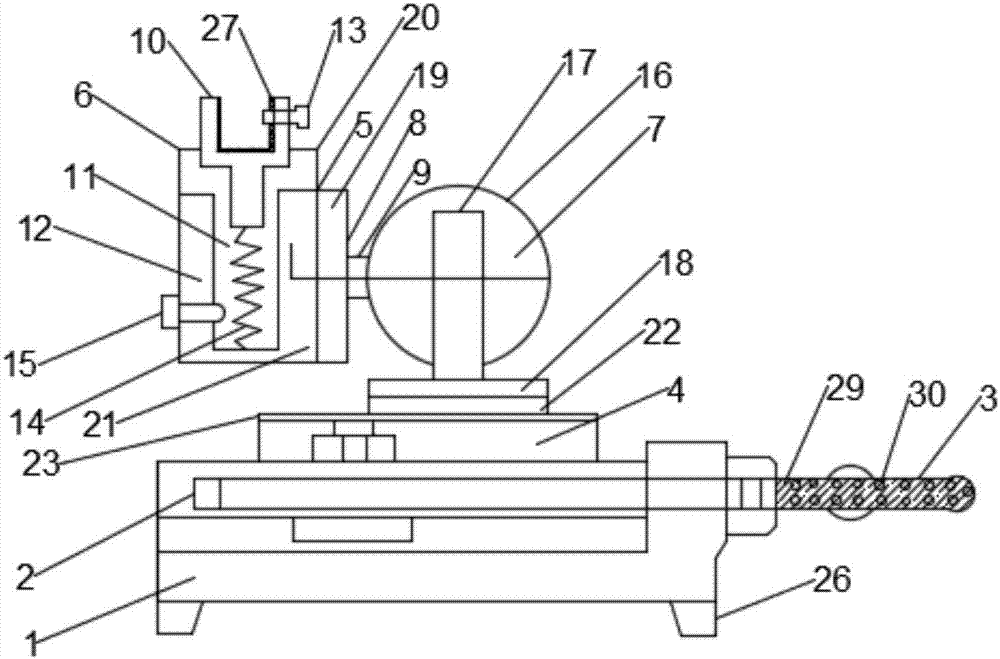

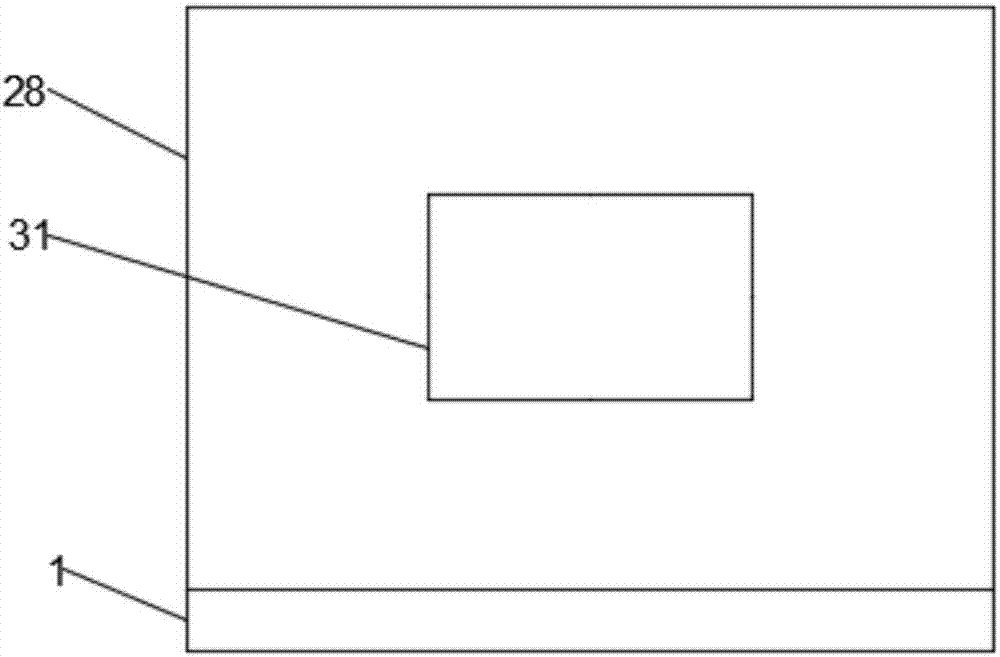

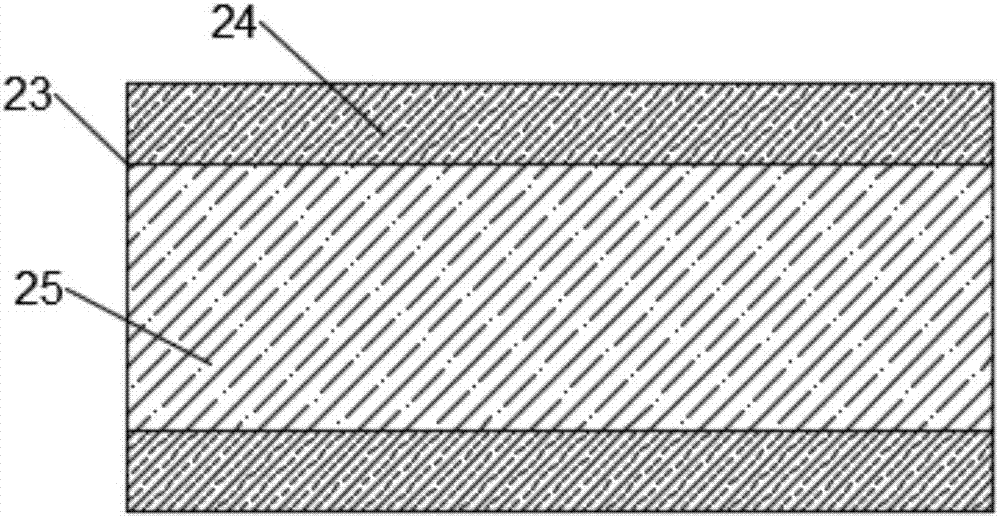

[0020] Such as figure 1 , figure 2 with image 3 As shown, the present invention provides a mechanical tool sharpening device, including a fixed base 1, the inside of the fixed base 1 is a hollow structure, the inside of the fixed base is provided with a screw 2, and the right end of the screw 2 extends To the outside of the fixed seat and connected to the handwheel 3, the top of the fixed seat 1 is provided with a base 4, the top of the base 4 is provided with a sharpening device 5, and the sharpening device 5 includes a knife rest 6, a first The swivel 7 and the second swivel 8, the first swivel 7 and the second swivel 8 are connected by bolts through a T-shaped slot 9, the second swivel 8 is connected with the knife holder 6 by screws, The tool rest 6 includes a tool holder 10, a sliding body 11 and a fixed frame 12, the tool holder 10 is used to place a tool, the tool holder 10 is arranged above the sliding body 11, and the tool holder 10 and the sliding body 11 They a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com