Precast box beam concrete construction method in winter in cold region

A technology of cold area and construction method, applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve the problems of unsteady maintenance temperature and humidity, imperfect construction technology in winter, etc., and achieve scientific construction technology, guaranteed strength, and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

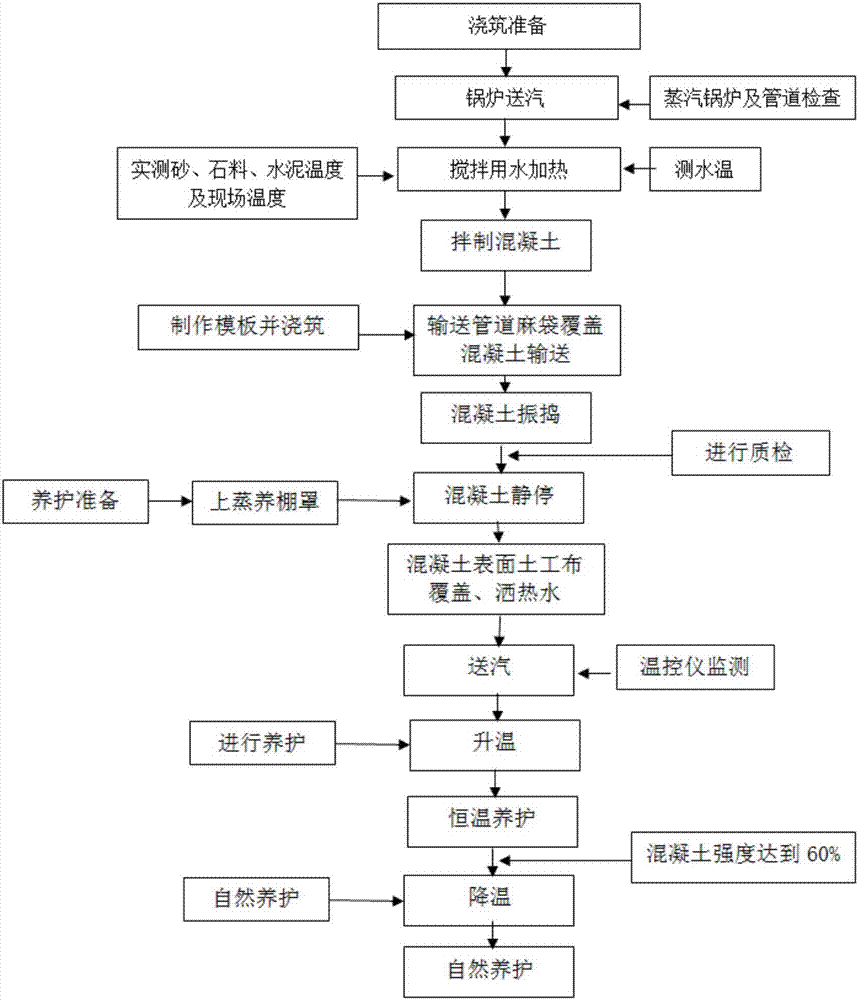

[0062] As mentioned above, according to the air temperature in the box girder prefabrication area, especially for the construction under cold winter conditions, a set of construction technology has been formulated by using the steam curing greenhouse combined with the temperature controller to automatically control the temperature and humidity. The construction steps are as follows:

[0063] ① Prefabrication and pouring preparation stage of box girder, mainly including inspection of steam boiler and pipeline, temperature measurement of on-site sand and gravel aggregate, steam delivery of steam boiler, concrete mixing water heating and other preparatory work:

[0064] (1.1) Collect the local weather forecast, record and measure the temperature t1 during construction, try to avoid pouring concrete when the temperature is low; try to choose the daytime when the temperature is high for the pouring time, and cover the raw materials such as sand and gravel yards with sheds to avoid ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com