Vibration reduction method for longitudinal torsional vibration of vehicle engine

A torsional vibration and engine technology, applied in vehicle components, power plants, jet propulsion devices, etc., can solve problems such as error characterization and errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0193]The present invention will be described in detail below in conjunction with the accompanying drawings and examples.

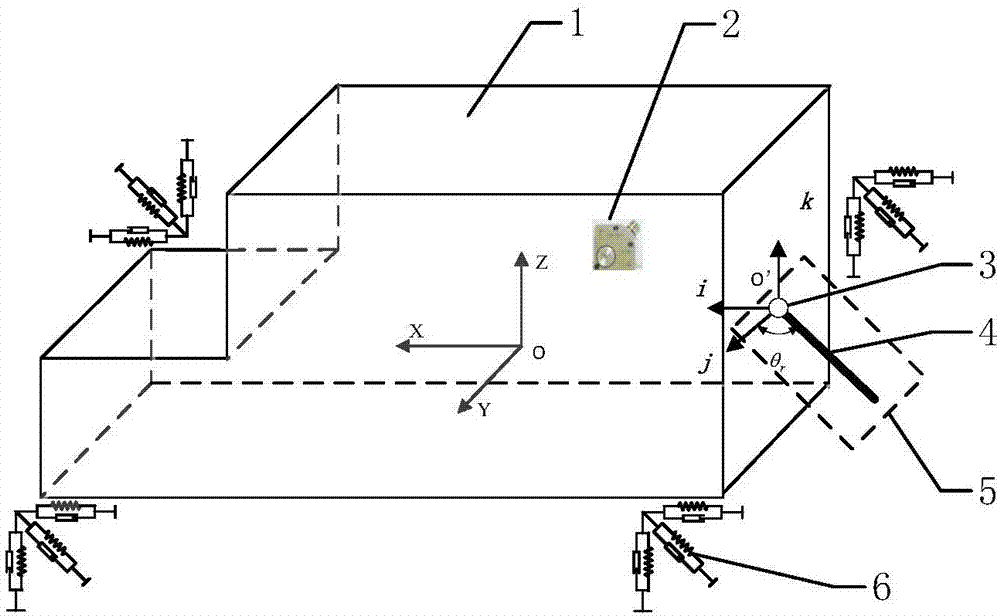

[0194] See figure 1 , The shock absorber 5 is made up of a servo motor 3 and a rigid strut 4. The vibration absorber 5 is installed on the four-cylinder engine 1, and the servo motor 3 drives the rigid strut 4 to move in the Oij plane. The coordinate system Oijk has the same direction as the coordinate system OXYZ. The engine 1 is connected to the vehicle body through four engine mounts 6 . The acceleration sensor 2 is installed on the engine 1 for measuring the acceleration of the engine 1 in six directions.

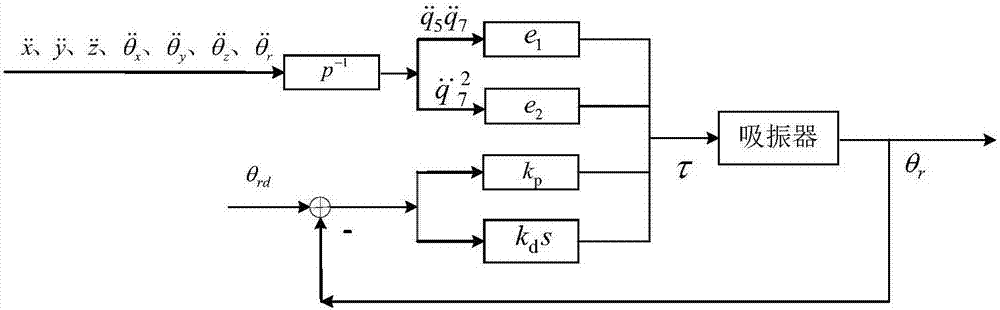

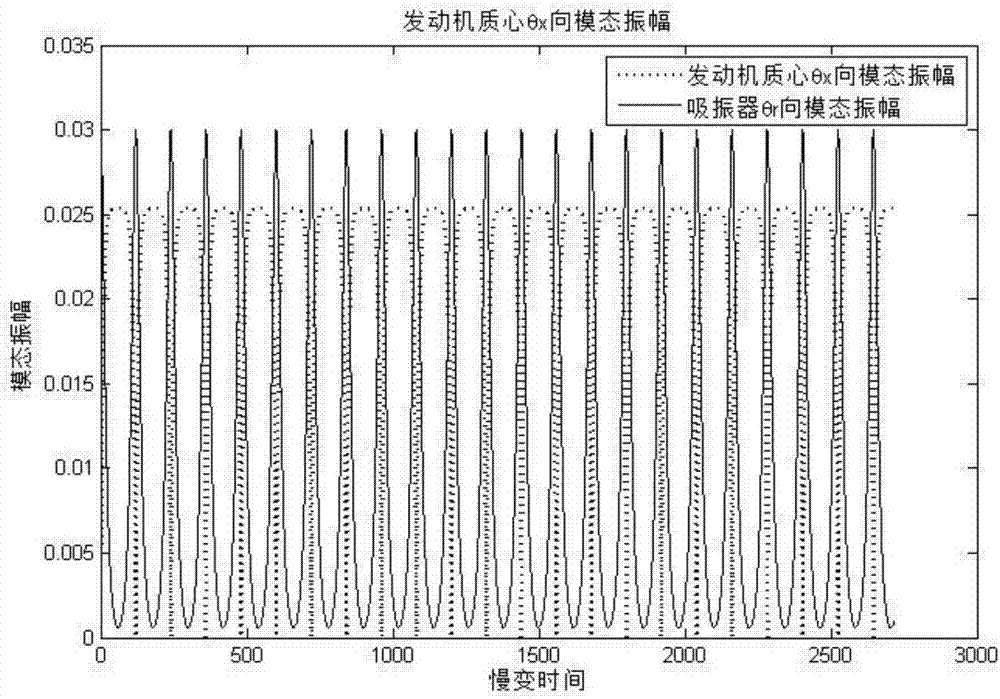

[0195] The invention discloses a vibration control method based on internal resonance energy consumption, which includes the establishment of a seven-degree-of-freedom dynamic equation of an engine added with a vibration absorber and internal resonance analysis. The specific implementation steps are as follows.

[0196] Step 1: Use the Lagrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com