A ubf reactor utilizing anammox-sulfur autotrophic denitrification coupling denitrification and its system and denitrification method

An anaerobic ammonium oxidation and coupled denitrification technology, applied in the field of wastewater treatment, can solve the problems of difficult to meet the requirements of wastewater denitrification, difficult to meet the requirements of wastewater, and high proportion requirements, so as to reduce the loss of autotrophic microorganisms and the production of sludge. The effect of less and lower operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

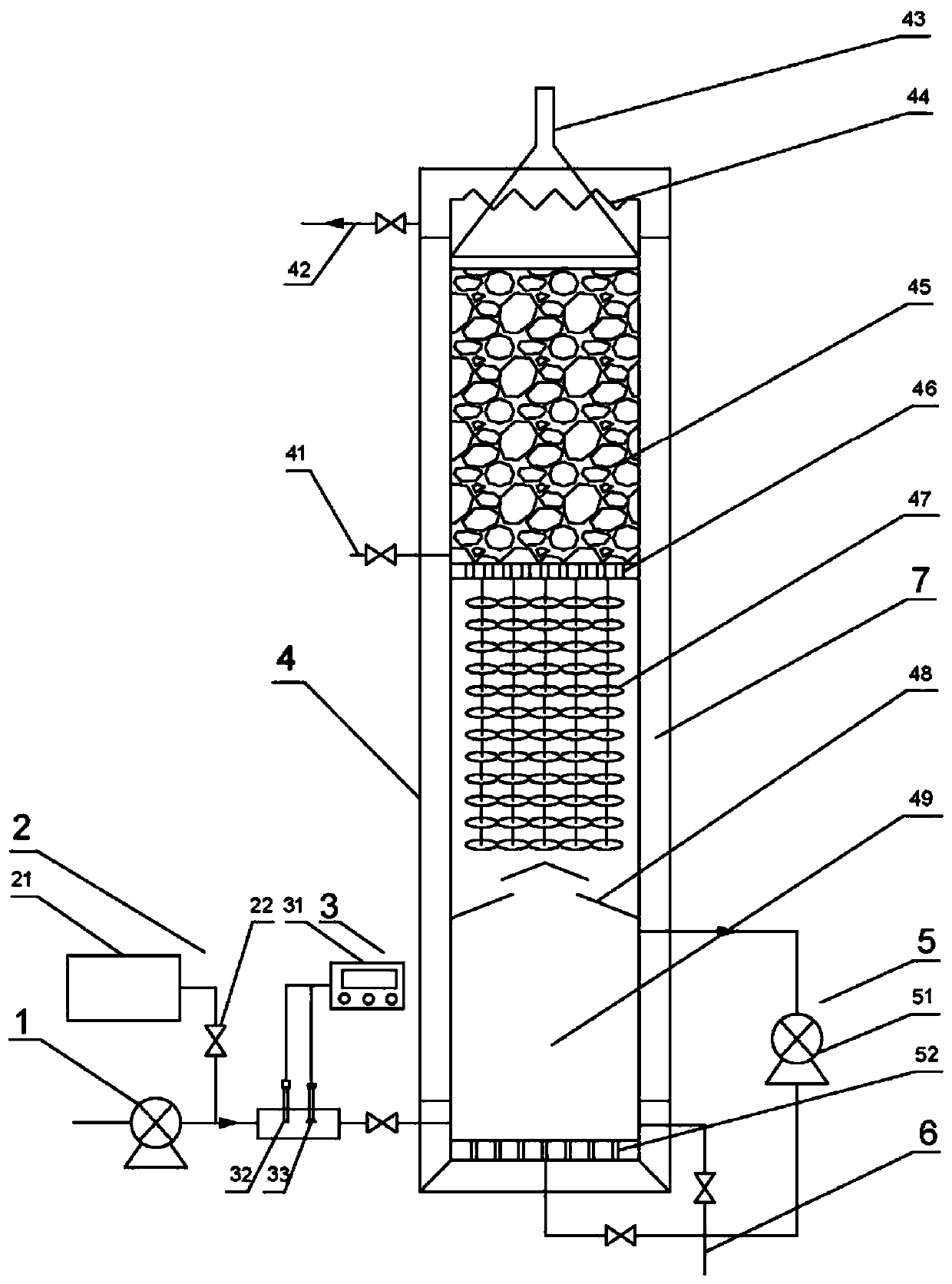

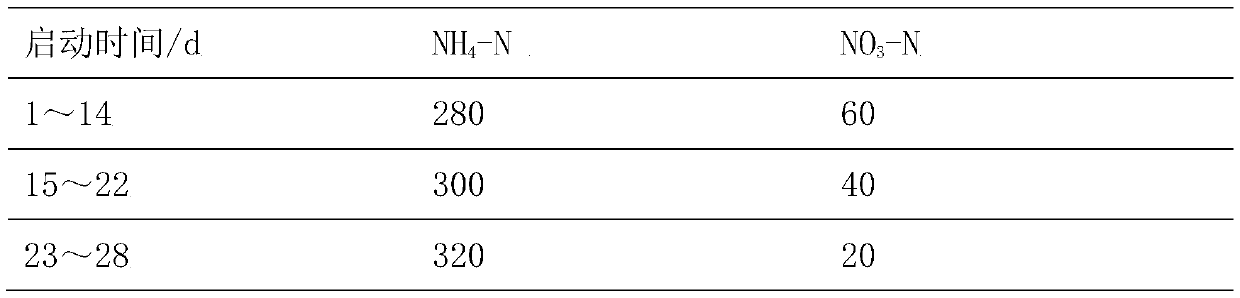

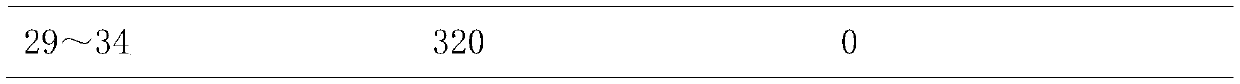

[0046] Such as figure 1 The device diagram shown is a UBF reactor using anaerobic ammonium oxidation-sulfur autotrophic denitrification coupling denitrification. The UBF reactor is divided into three parts from bottom to top, which are respectively suspended sludge area 49 and braided packing Area 47 and marcasite packing area 45, slow flow baffle 48 is set between suspended sludge area 49 and braided packing area 47, porous support is set between braided packing area 47 and marcasite packing area 45 Layer 46. The outer layer of the UBF reactor is provided with a thermal insulation layer 7 . The upper part of the porous supporting layer 46 is provided with a sampling port 41, and the top of the UBF reactor is provided with a three-phase separator 43 and an overflow weir 44, and the effluent of the UBF reactor is discharged through the outlet. Porous supporting layer 46 is porous limestone, porous limestone is used as supporting frame (porosity reaches 50%~60%), and the pore ...

Embodiment 2

[0054] The UBF reactor and its system are the same as in Example 1, except that the parameters set are: the height ratio of the suspended sludge area, the braided packing area and the marcasite packing area is 1.4:1:0.8; The diameter ratio of the inner and outer layers is 1:1.1, and the height-to-diameter ratio is 5:1; the average diameter of the equal surface area of sulfide precipitation is 0.6cm, and the average pore diameter of the porous supporting layer is 0.3cm.

[0055] The specific steps are the same as in Example 1, except that the control parameters of the process are as follows: the control parameters of the process are that the influent is aerated, DO rises to about 1.3mg / L, and the pH is adjusted to about 8 by adding acid and alkali; The hydraulic retention time of the UBF reactor is 6h; the reflux ratio in the suspended sludge area is 5:1; the DO concentration range at the sampling port at the bottom of the marcasite filling area is controlled below 0.2mg / L, an...

Embodiment 3

[0057] The UBF reactor and its system are the same as in Example 1, except that the parameters set are as follows: the height ratio of the suspended sludge area, the braided packing area and the marcasite packing area is 1.5:1:0.8; The diameter ratio of the inner and outer layers is 1:1.2, and the height-to-diameter ratio is 6:1; the average diameter of the equal surface area of sulfide precipitation is 0.7cm, and the average pore diameter of the porous supporting layer is 0.4cm.

[0058] The specific steps are the same as in Example 1, except that the control parameters of the process are as follows: the control parameters of the process are that the influent is aerated, DO rises to about 1.5mg / L, and the pH is adjusted to about 9 by adding acid and alkali; The hydraulic retention time of the UBF reactor is 7h; the reflux ratio in the suspended sludge area is 6:1; the DO concentration range at the sampling port at the bottom of the marcasite filling area is controlled below ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com