A kind of coal water slurry and preparation method thereof

A technology of coal-water slurry and slurry, which is applied in the field of coal chemical industry to achieve the effect of filling the accumulation space, saving space, and low-consumption production requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

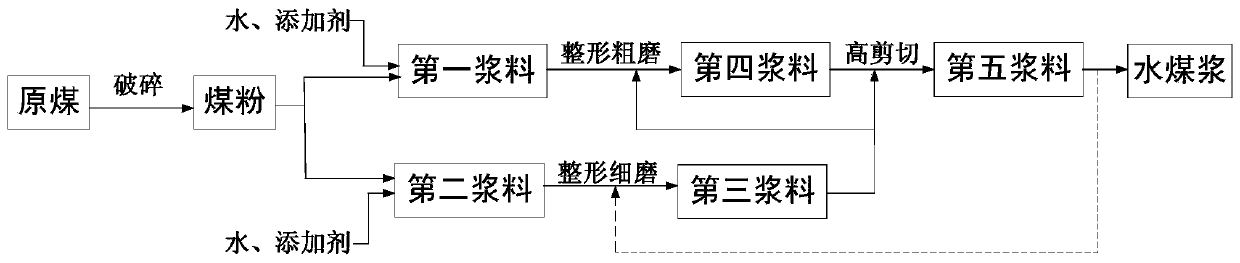

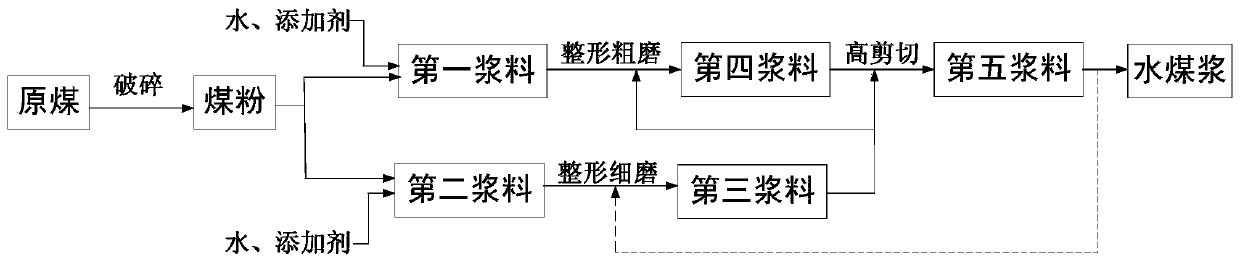

[0041] A kind of coal water slurry, it is prepared by following steps:

[0042] 1) crushing Shenfu coal to obtain coal powder with a particle size less than 5mm, mixing 60wt% of coal powder with water and naphthalenesulfonic acid formaldehyde condensate according to a mass ratio of 70:30:0.1 to obtain the first slurry; The remaining coal powder is mixed with naphthalenesulfonic acid formaldehyde condensate and water according to the mass ratio of 90:10:0.5 to obtain the second slurry;

[0043] 2) Shaping and finely grinding the second slurry to obtain a third slurry with a particle size of 16-20 μm, mixing the first slurry with 5wt% of the third slurry for shaping and coarse grinding to obtain a fourth slurry with a particle size of 75~90μm;

[0044] 3) mixing the fourth slurry with the remaining third slurry, and performing high shear at a rate of 80r / min to obtain the fifth slurry;

[0045] 4) The fifth slurry is output to obtain coal water slurry.

[0046] The concentrat...

Embodiment 2

[0048] A kind of coal water slurry, it is prepared by following steps:

[0049] 1) crushing Yulin coal in Shaanxi to obtain coal powder with a particle size less than 5mm, mixing 99wt% of coal powder with water and humate according to a mass ratio of 90:10:1 to obtain the first slurry; The powder is mixed with naphthalenesulfonic acid formaldehyde condensate and water according to the mass ratio of 70:30:1 to obtain the second slurry;

[0050] 2) Shaping and finely grinding the second slurry to obtain a third slurry with a particle size of 5-10 μm, mixing the first slurry with 40 wt% of the third slurry for shaping and coarse grinding to obtain a fourth slurry with a particle size of 35~50μm;

[0051] 3) Mix the fourth slurry with the remaining third slurry, and perform high shear at a rate of 150r / min to obtain the fifth slurry; 5wt% of the fifth slurry is returned to step 2) for shaping and fine grinding;

[0052] 4) The remaining fifth slurry is exported to obtain coal wa...

Embodiment 3

[0055] A kind of coal water slurry, it is prepared by following steps:

[0056] 1) crushing Shenfu coal to obtain coal powder with a particle size of less than 5mm, mixing 60wt% of coal powder with water and lignosulfonate according to a mass ratio of 75:25:0.5 to obtain the first slurry; The pulverized coal is mixed with lignin sulfonate and water according to the mass ratio of 70:30:0.5 to obtain the second slurry;

[0057] 2) Shaping and finely grinding the second slurry to obtain the third slurry with a particle size of 10-15 μm, mixing the first slurry with 30 wt% of the third slurry for shaping and coarse grinding to obtain the fourth slurry with a particle size of 50~60μm;

[0058] 3) Mix the fourth slurry with the remaining third slurry, and perform high shear at a rate of 100r / min to obtain the fifth slurry; 40wt% of the fifth slurry is returned to step 2) for shaping and fine grinding;

[0059] 4) The remaining fifth slurry is exported to obtain coal water slurry. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com