Processing process of flavor table vinegar in parched rice color

A processing technology and technology of edible vinegar, which is applied in the field of processing technology of fried beige-flavored edible vinegar, can solve the problems of lack of mellow and soft feeling, flavor, poor color, not strong aroma, etc., and achieve improved vinegar flavor, unique flavor, Nutrient-rich effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

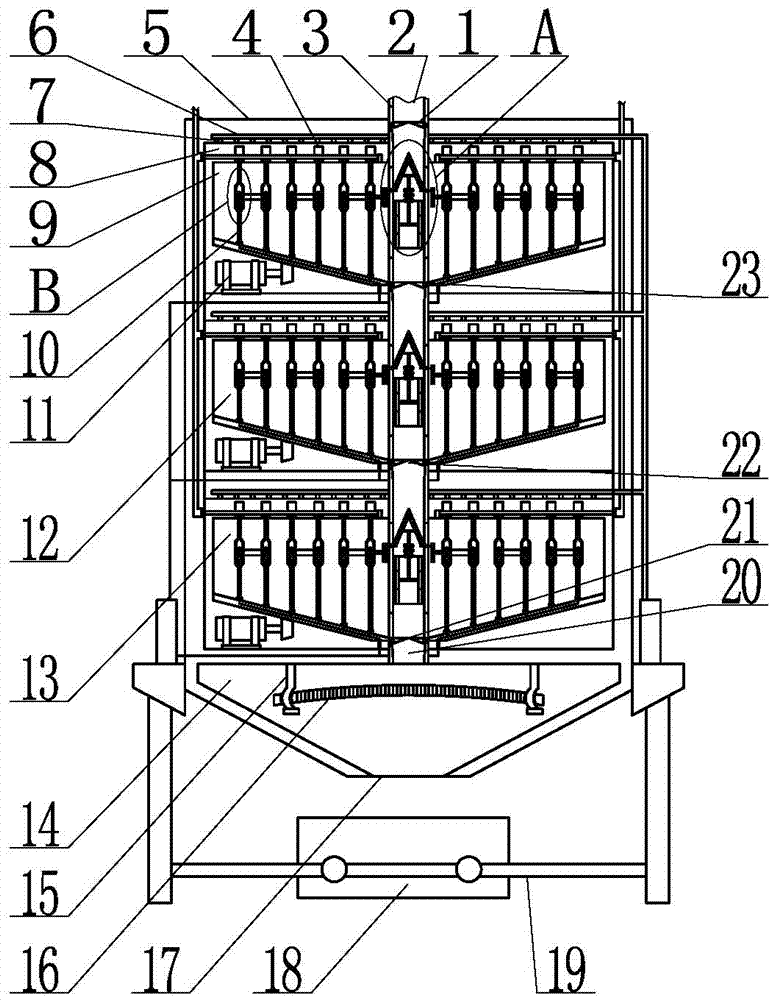

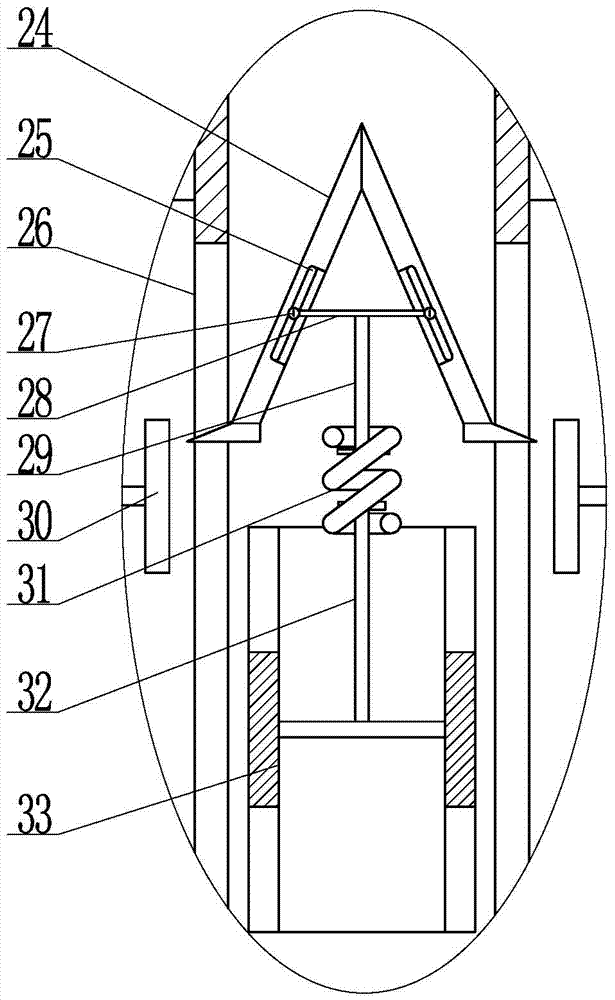

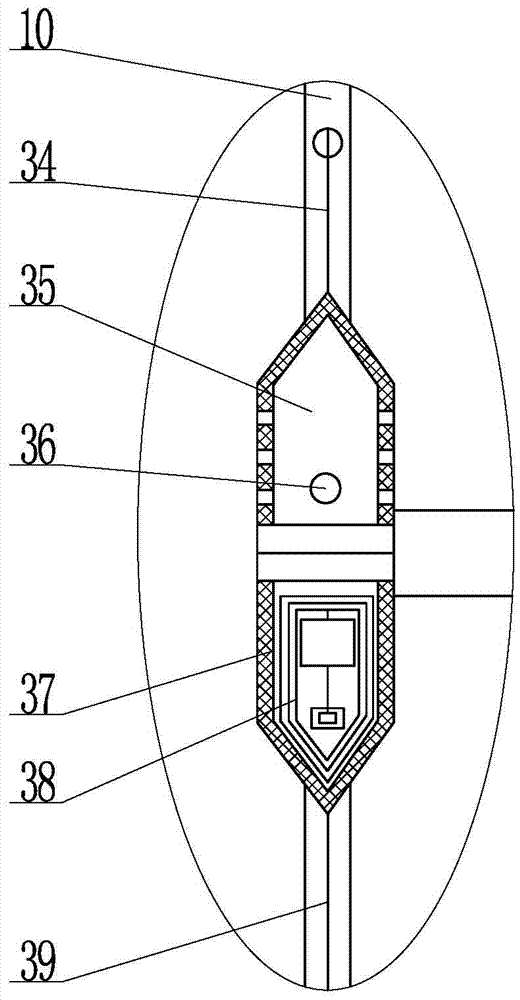

[0052] Such as figure 1 Shown, the processing technology of a kind of fried beige flavor edible vinegar of the present invention, comprises the steps:

[0053] (1) Fried rice:

[0054] a. Add 100 kg of rice into the intelligent homogeneous rice fryer, enter the first stage of low-temperature frying, and the frying time is 3-5 minutes;

[0055] b. Enter the second stage of baking at medium temperature, and the baking time is 5-8 minutes;

[0056] c. Enter the third stage of high-temperature roasting, and the roasting time is 25-30 minutes; after completing the three stages of roasting, fried rice is obtained;

[0057] (2) Seasoning: Add 0.5-1 kg of compound spices and 2-5 kg of soy sauce pressed cake granules to the fried rice, speed up the stirring to prevent paste, and when the rice is all oily, it will form a large rice ball, stop stirring, and leave spare material;

[0058] (3) Liquid preparation: Immediately put the discharged material into hot water at 90-95°C, stir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com