A processing technology of fried beige-flavored edible vinegar

A processing technology and edible vinegar technology, which is applied to the processing technology field of fried beige flavored edible vinegar, can solve the problems of lack of mellow and soft feeling, flavor, poor color and luster, not strong aroma, etc., so as to improve the flavor of vinegar, unique flavor, Nutritious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

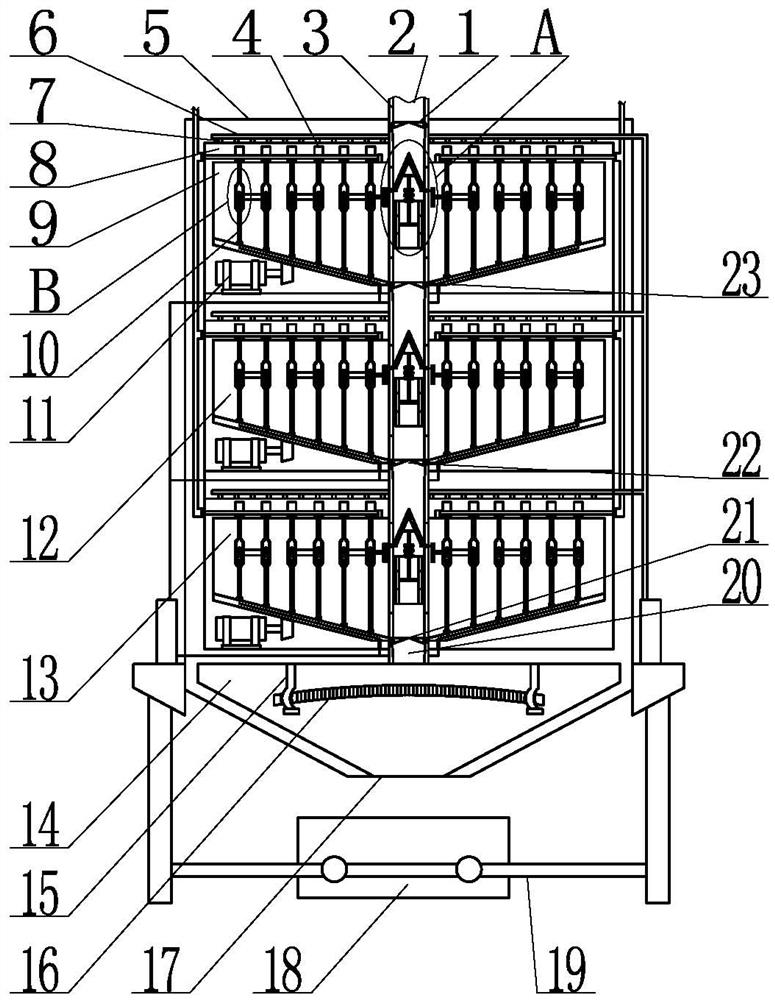

[0052] Such as figure 1 Shown, the processing technology of a kind of fried beige flavor edible vinegar of the present invention, comprises the steps:

[0053] (1) Fried rice:

[0054] a. Add 100 kg of rice into the intelligent homogeneous rice fryer, enter the first stage of low-temperature frying, and the frying time is 3-5 minutes;

[0055] b. Enter the second stage of baking at medium temperature, and the baking time is 5-8 minutes;

[0056] c. Enter the third stage of high-temperature roasting, and the roasting time is 25-30 minutes; after completing the three stages of roasting, fried rice is obtained;

[0057] (2) Seasoning: Add 0.5-1 kg of compound spices and 2-5 kg of soy sauce pressed cake granules to the fried rice, speed up the stirring to prevent paste, and when the rice is all oily, it will form a large rice ball, stop stirring, and leave spare material;

[0058] (3) Liquid preparation: Immediately put the discharged material into hot water at 90-95°C, stir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com