Multi-stage beating device for textile fibers

A textile fiber and power device technology, which is applied in the field of textile fiber multi-stage beating devices, can solve the problems of incomplete beating of pulp and difficulty in beating pulp fully, so as to avoid thorough beating, improve the crushing effect, and improve the chopping effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

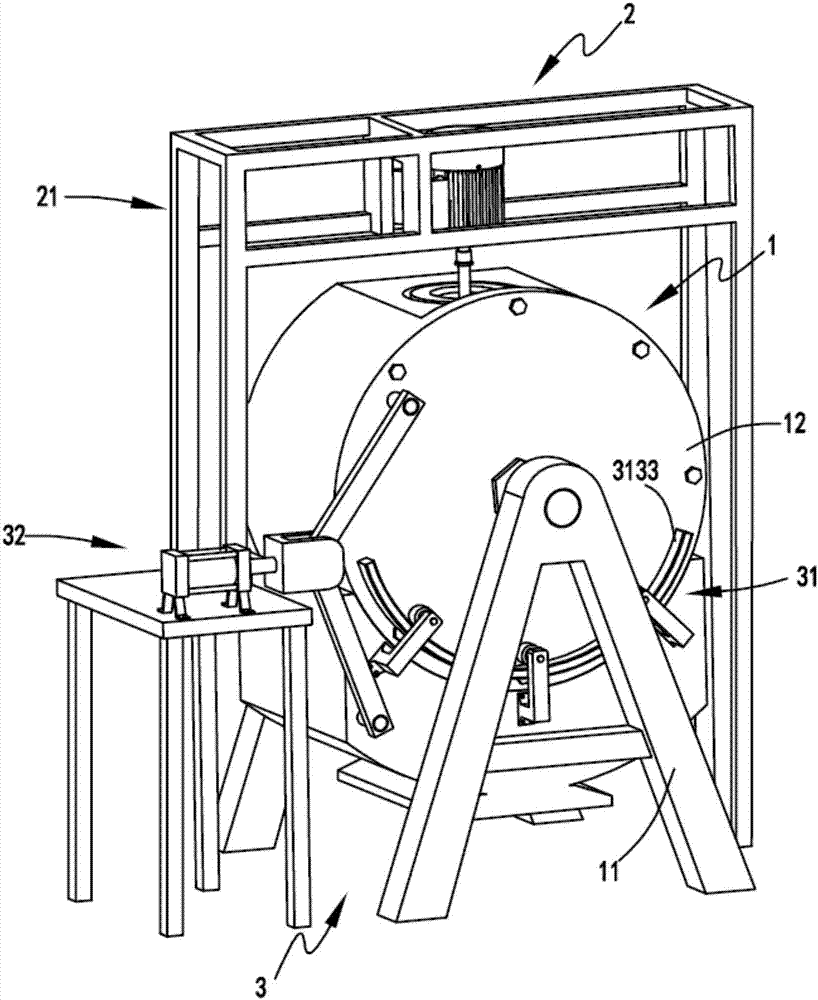

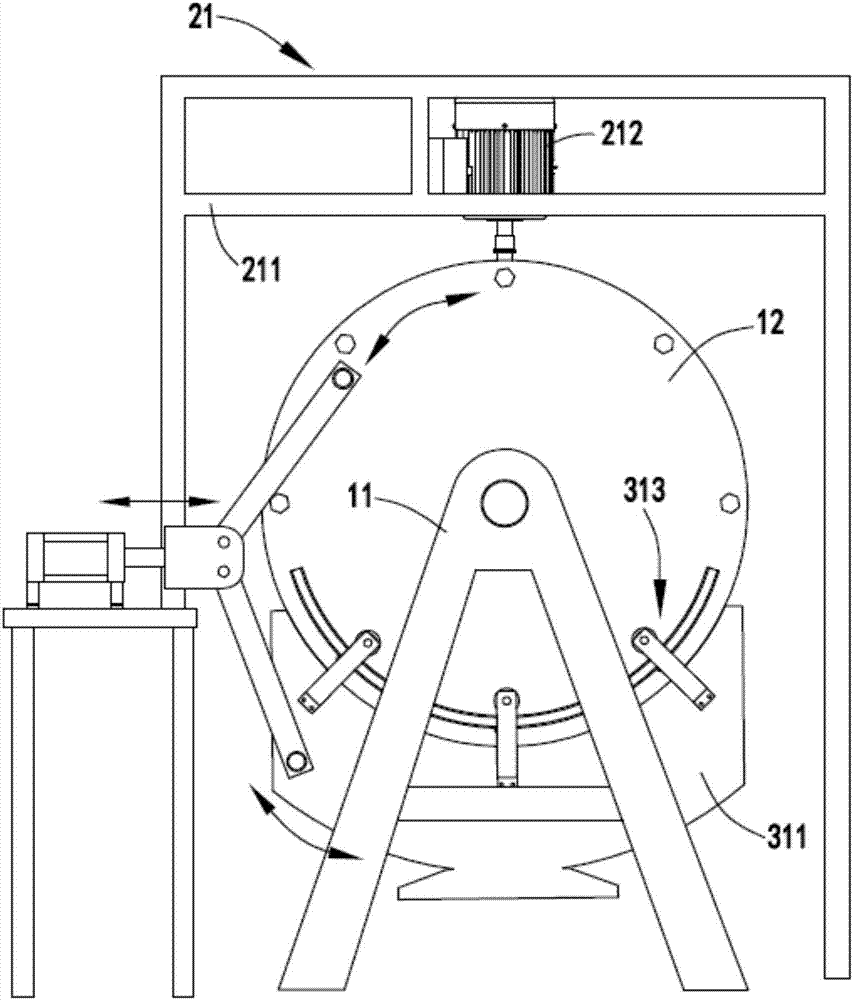

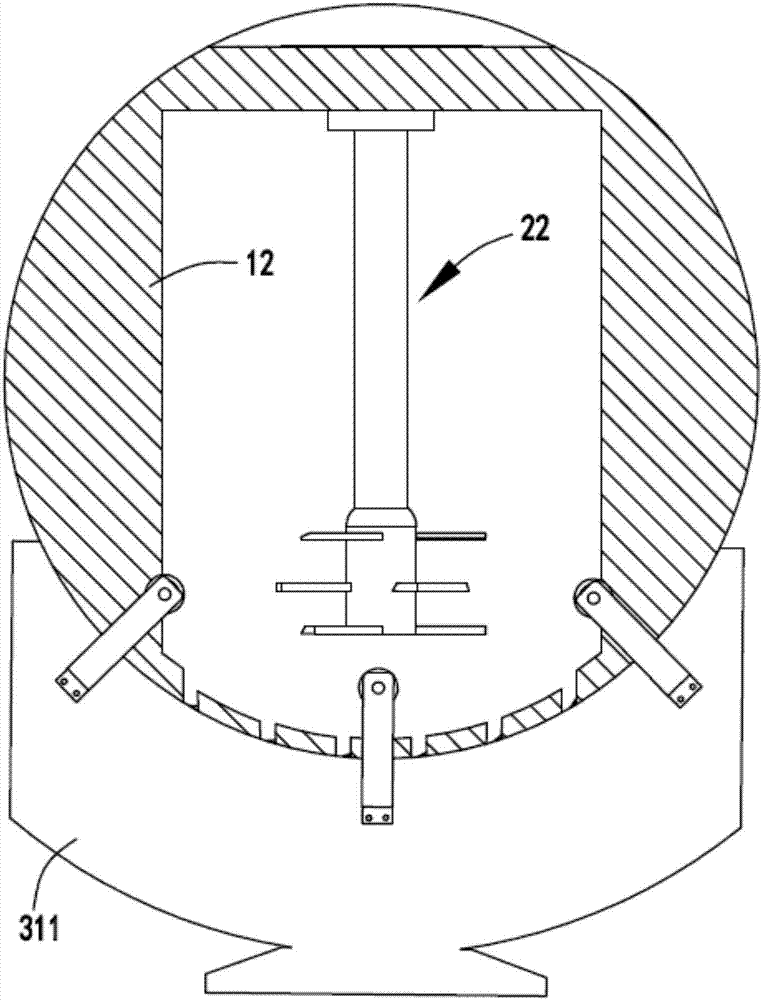

[0034] figure 1 It is a schematic diagram of the structure of the secondary beating equipment, figure 2 It is a schematic diagram of the front view of the secondary beating equipment, image 3 It is a cutaway diagram of the slurry tank, Figure 4 It is a cut-away schematic diagram of the secondary beating part, Figure 5 It is an enlarged schematic diagram of the relative position of cutter a and cutter b, Image 6 It is a schematic diagram of the structure of the rotating discharge member and the driving mechanism, Figure 7 It is a schematic diagram of the structure of the first-stage beating device. like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 and Figure 7 As shown, a textile fiber multistage beating device includes a main body 1, the main body 1 includes a support frame 11 and a slurry barrel 12 rotatably arranged on the support frame 11 for placing pulp to be beaten;

[0035] A first-stage beating part 2, the first-stage beating pa...

Embodiment 2

[0052] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 and Figure 7 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between the second embodiment and the first embodiment is that: further, the rotating support device 313 includes a turret 3131 fixedly arranged on both sides of the rotating discharge member 311, and rollers rotatably arranged on the turret 3131 3132 and arc-shaped support rails 3133 arranged on both sides of the slurry bucket 12, the rollers 3132 roll along the arc-shaped support rails 3133;

[0053] By setting the track 3133, the roller 3132 can rotate directionally, and the track 3133 is set along the circumferential trajectory of the slurry bucket 12, so that the trajectory of the rotating d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com