Combustion zone pore step type porous medium burner

A technology of porous medium and porous medium layer, applied in the direction of gas fuel burners, burners, combustion methods, etc., can solve problems such as uneven flame distribution, uneven temperature distribution, and unstable flame, so as to improve combustion efficiency and avoid Temperature gradient, the effect of solving uneven flame distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

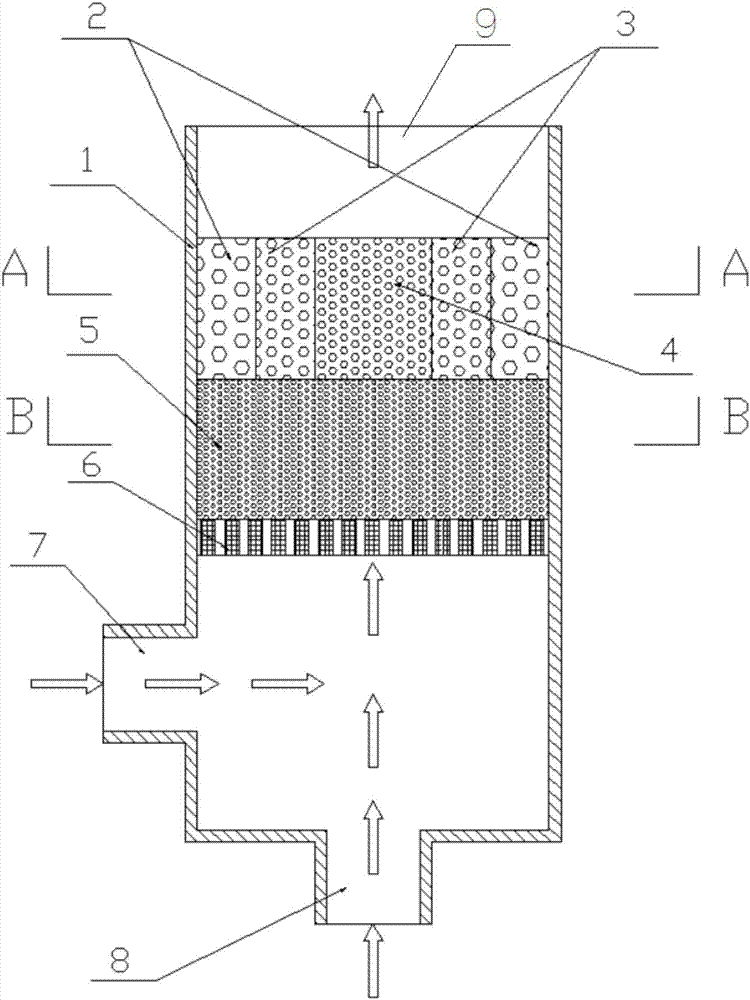

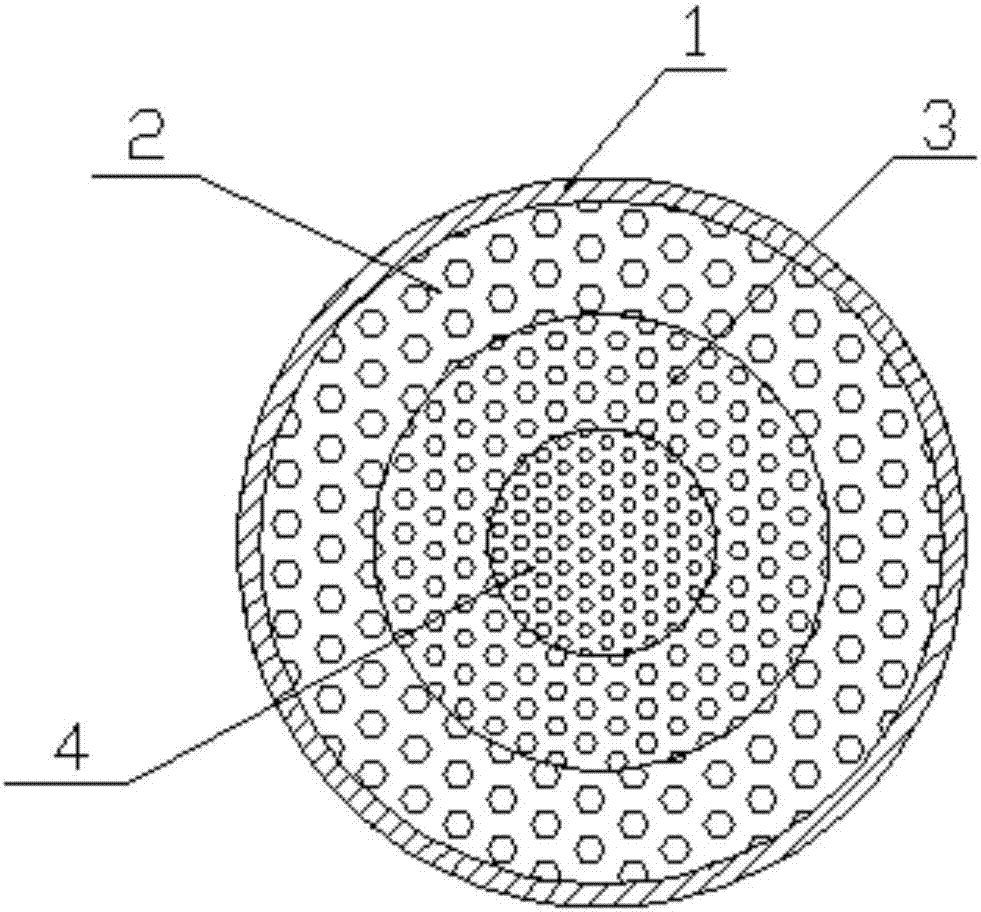

[0033] Such as Figure 1 to Figure 3 As shown, this embodiment proposes the first preferred porous media burner with stepped pores in the combustion zone. The stepped porous media burner in the combustion zone includes a burner shell 1, and the shape of the burner shell 1 can be a circle Cylindrical or square cylindrical, also can be other shapes. The bottom of the burner casing 1 is provided with a gas inlet 8 through which gas can enter the burner casing 1 . An air inlet 7 is arranged on the side wall of the burner casing 1 near the bottom, and air can enter the burner casing 1 through the air inlet 7 . Compared with the existing air inlet 7 and gas inlet 8 which are arranged at the bottom or on the same side, the gas inlet 8 of this embodiment is arranged perpendicular to the air inlet 7, so that the air and gas can be well Mixed together, the combustion is more complete and the combustion efficiency is high.

[0034] The top of the burner casing 1 is provided with a flu...

Embodiment 2

[0046] This embodiment proposes the second preferred porous media burner with stepped pores in the combustion zone. The structure of the porous media burner is basically the same as that of the porous media burner described in Example 1, and the differences are as follows:

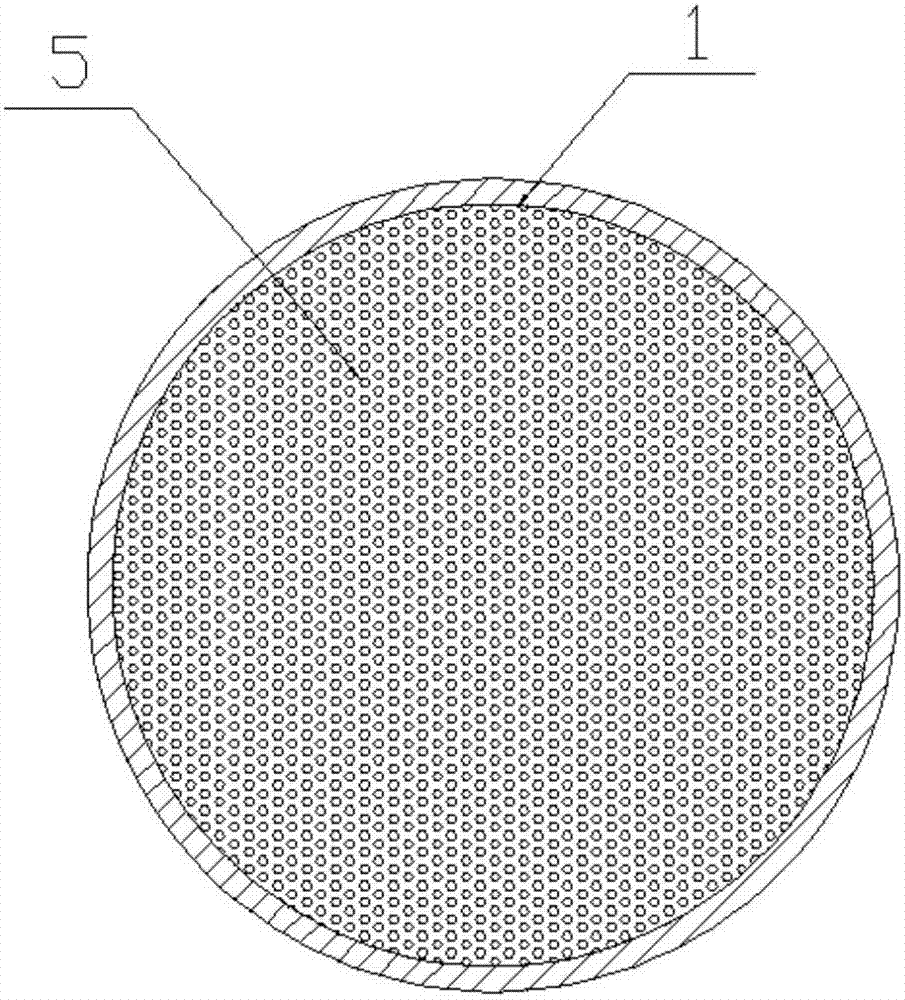

[0047] like Figure 4 As shown, in the present embodiment, the preheating zone 5 is filled with a porous medium with a pore density of 50PPI, and the preheating zone 5 is selected to have a plate thickness of 30mm and a macroporous ceramic foam plate with a porosity of more than 80%. Compared with the plate thickness of the preheating zone 5 in 1, the plate thickness is relatively increased, which prolongs the preheating time and improves the preheating effect.

[0048] The two annular porous medium layers and the central porous medium layer in the combustion zone jointly form a small-pore foam ceramic plate with a plate thickness of 30mm and a porosity of more than 80%. The outermost annular porous mediu...

Embodiment 3

[0051] This embodiment proposes a third preferred porous media burner with stepped pores in the combustion zone. The structure of the porous media burner is basically the same as that of the porous media burner described in Example 1, and the differences are as follows:

[0052] like Figure 5 As shown, in the present embodiment, the preheating zone 5 is filled with a porous medium with a pore density of 55PPI, and the preheating zone 5 selects a plate thickness of 40mm and a macroporous ceramic foam plate with a porosity of more than 80%. The plate thickness of the preheating zone 5 in Example 2 is thicker, the preheating time is prolonged, and the preheating effect is further improved.

[0053] The two annular porous medium layers and the central porous medium layer in the combustion zone jointly form a small-pore foam ceramic plate with a plate thickness of 40mm and a porosity of more than 80%. The outermost annular porous medium layer 2 is filled with a porous medium with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hole density | aaaaa | aaaaa |

| Hole density | aaaaa | aaaaa |

| Plate thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com