Automatic assembly machine for nesting screw lamp holder on lamp body

A screw lamp holder and assembly machine technology, which is applied in the direction of lighting devices, semiconductor devices of light-emitting elements, light sources, etc., can solve problems such as difficult to realize automation, difficult to pass through holes, and uncertain positions, so as to achieve the effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

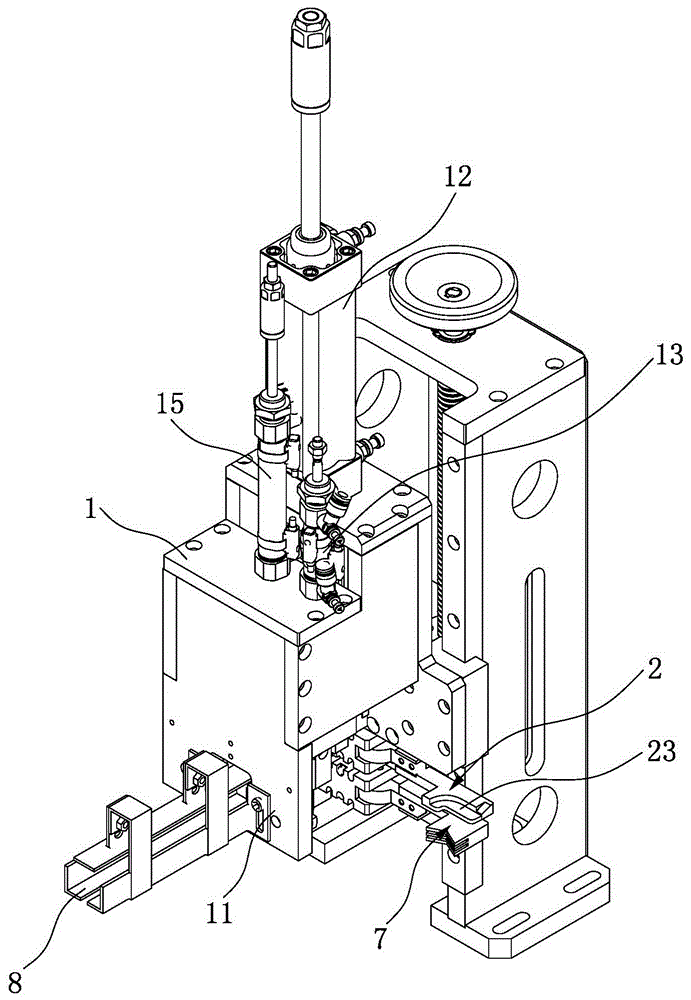

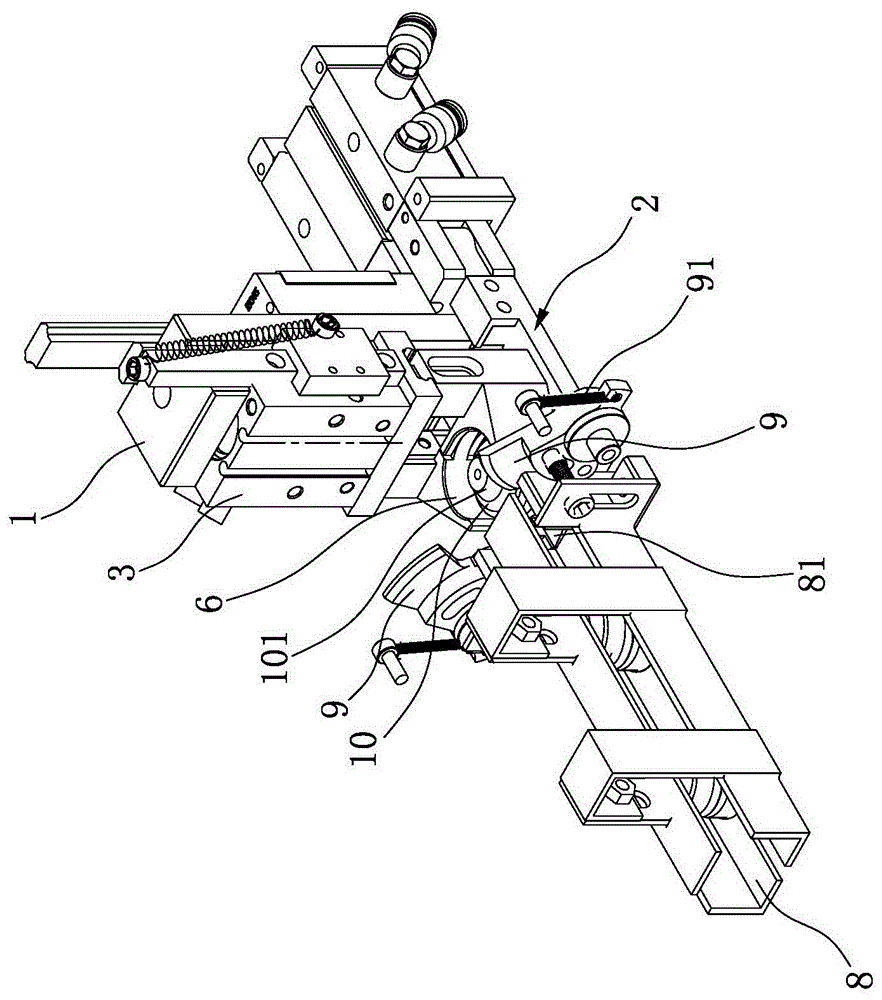

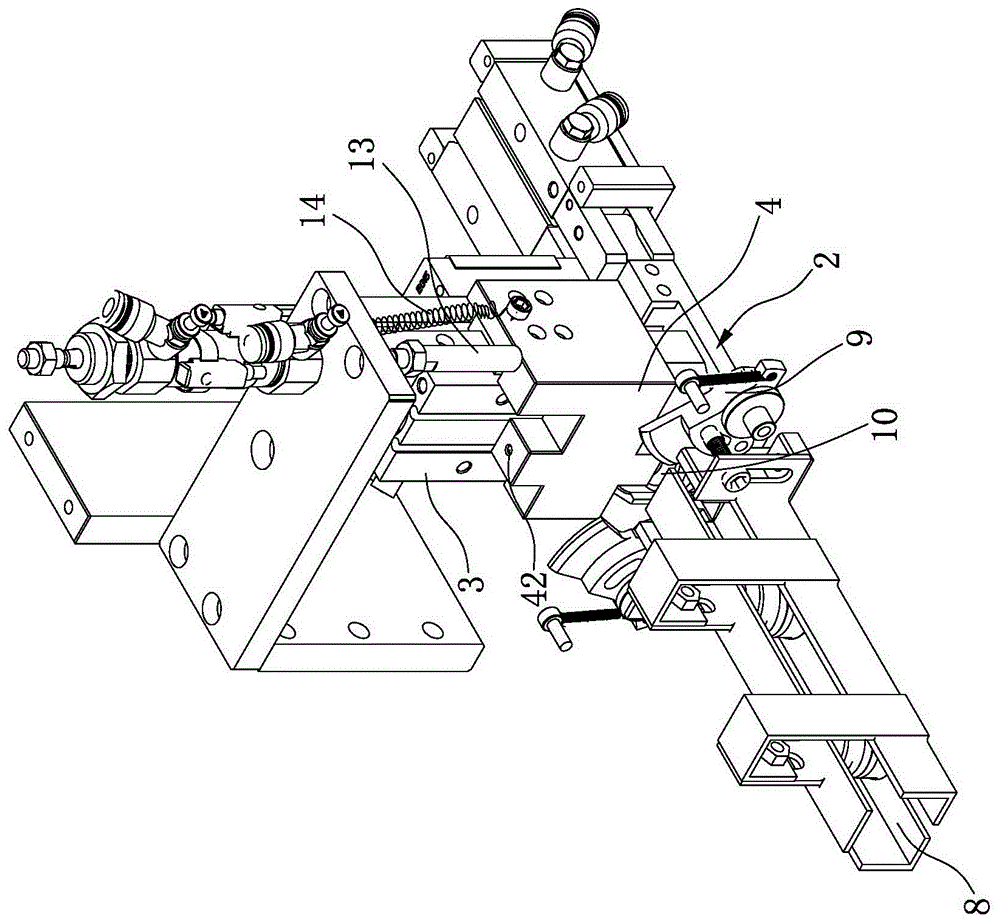

[0059] combine figure 1 , Figure 4 and Figure 8 As shown, the present invention discloses an automatic assembly machine for placing the screw cap on the lamp body, mainly including a frame 1, a pneumatic receiving claw 2, a socket 3, a positioning seat 4, a needle tube 5, and a pneumatic screw Holding claw 6, pneumatic wire holding claw 7 and controller.

[0060] The pneumatic receiving claw 2 is installed on the frame 1, such as Figure 4As shown, it consists of a left receiving claw 21 and a right receiving claw 22 that can be opened and closed. When the pneumatic receiving claw 2 is closed, its upper surface is used to receive and place the screw lamp cap 10 . As an optimization, the upper surfaces of the left receiving claw 21 and the right receiving claw 22 jointly form a receiving groove 23, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com