Calender used for plastic cement calendering

A calender and plastic technology, applied in the field of calenders for calendering plastics, can solve problems such as inconsistent roller speeds of calenders, reduced working efficiency of calenders, and single functions, and achieve good calendering effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

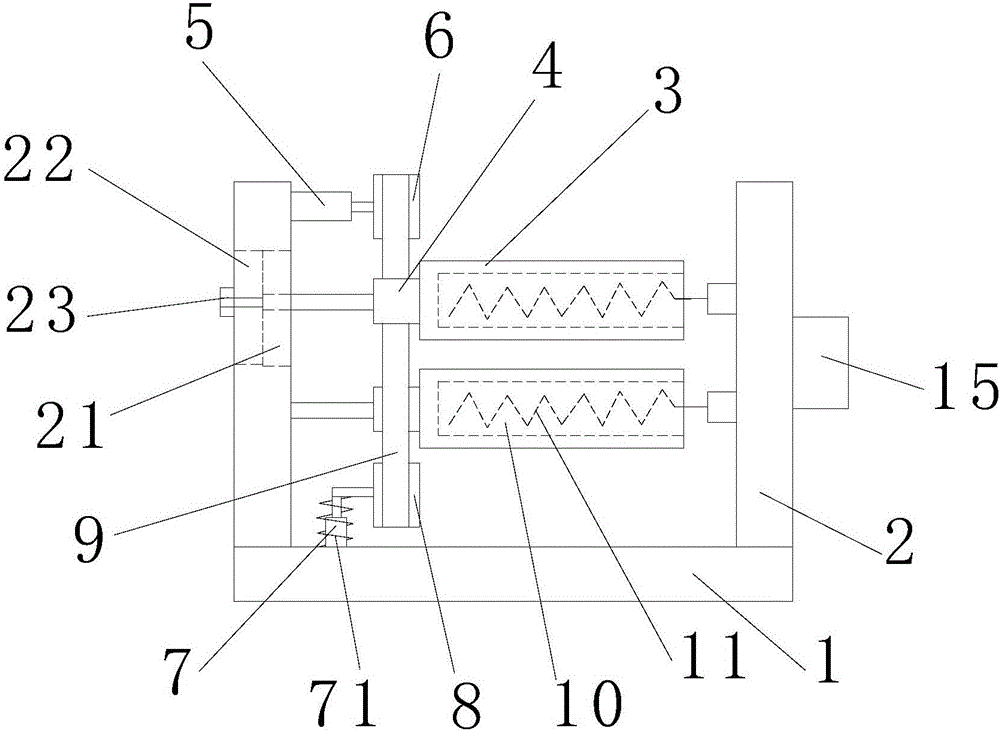

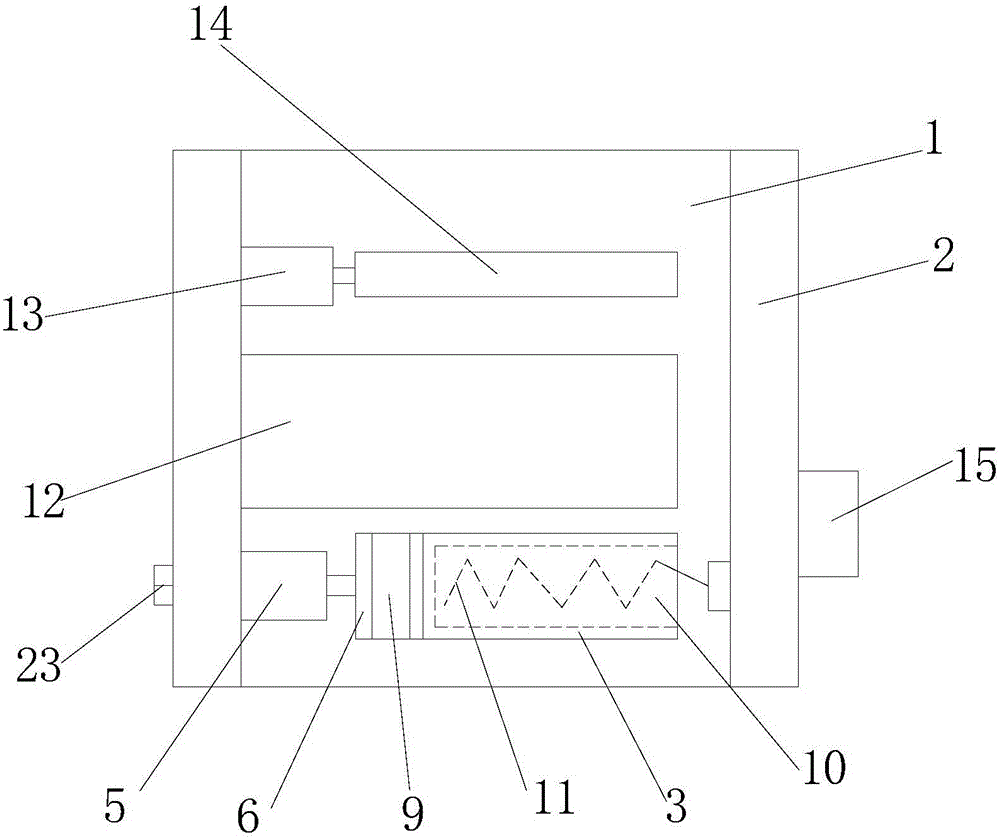

[0017] refer to figure 1 and 2 , a calender for calendering plastics according to the present invention, comprising a base 1, a side plate 2, a roller 3, a roller 4, a first motor 5, a driving wheel 6, a mounting rod 7, a driven wheel 8, a transmission belt 9, and an accommodation chamber 10. Heating wire 11, material receiving plate 12, second motor 13, take-up roller 14 and controller 15, the base 1 is provided with two vertical side plates 2, and the left side plate 2 The right side of the left side is rotated from top to bottom with two rollers 3, and the left side of the roller 3 is provided with a roller 4 fixedly connected with the roller 3, and the right side of the side plate 2 on the left side is located on the upper side. The top of the roller 3 on the side is fixedly provided with the first motor 5 whose rotating shaft is parallel to the central axis of the roller 3, and the output shaft of the first motor 5 is fixedly provided with a drive wheel 6, and the roller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com