Variable printing sprayer angle printing equipment of assembly line gantry structure based on FDM

A technology for printing nozzles and printing equipment, used in 3D object support structures, metal processing equipment, manufacturing tools, etc., can solve the problems of simultaneous printing, inability to automatically peel off the printed entities, and inability to achieve batch printing, etc., to reduce The effect of support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

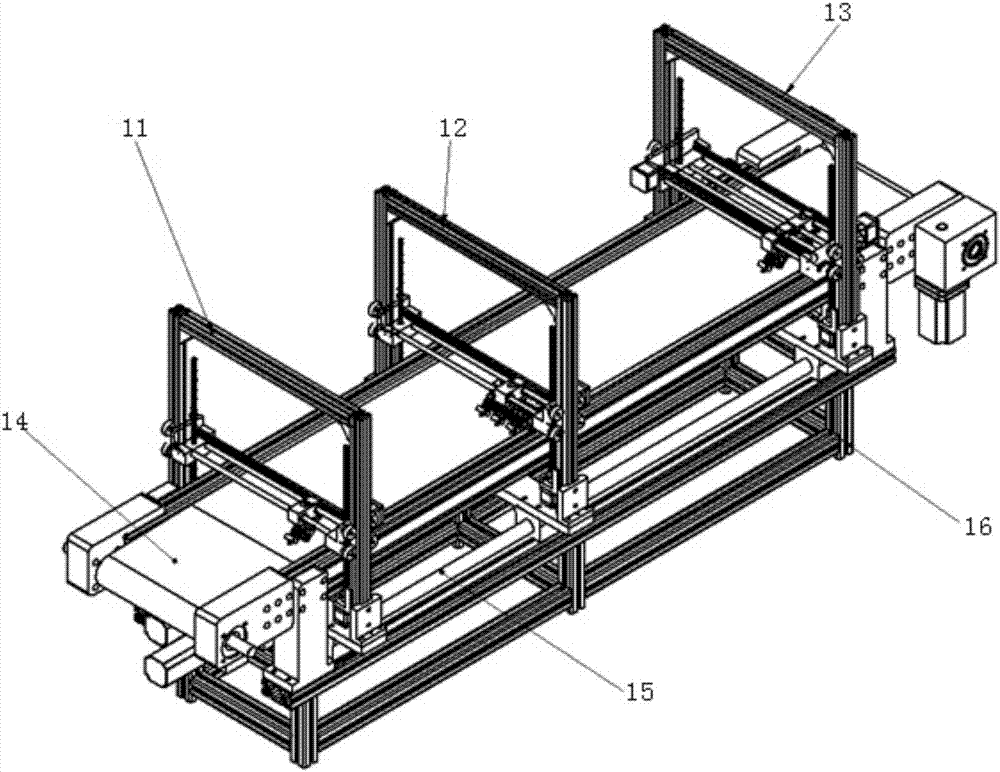

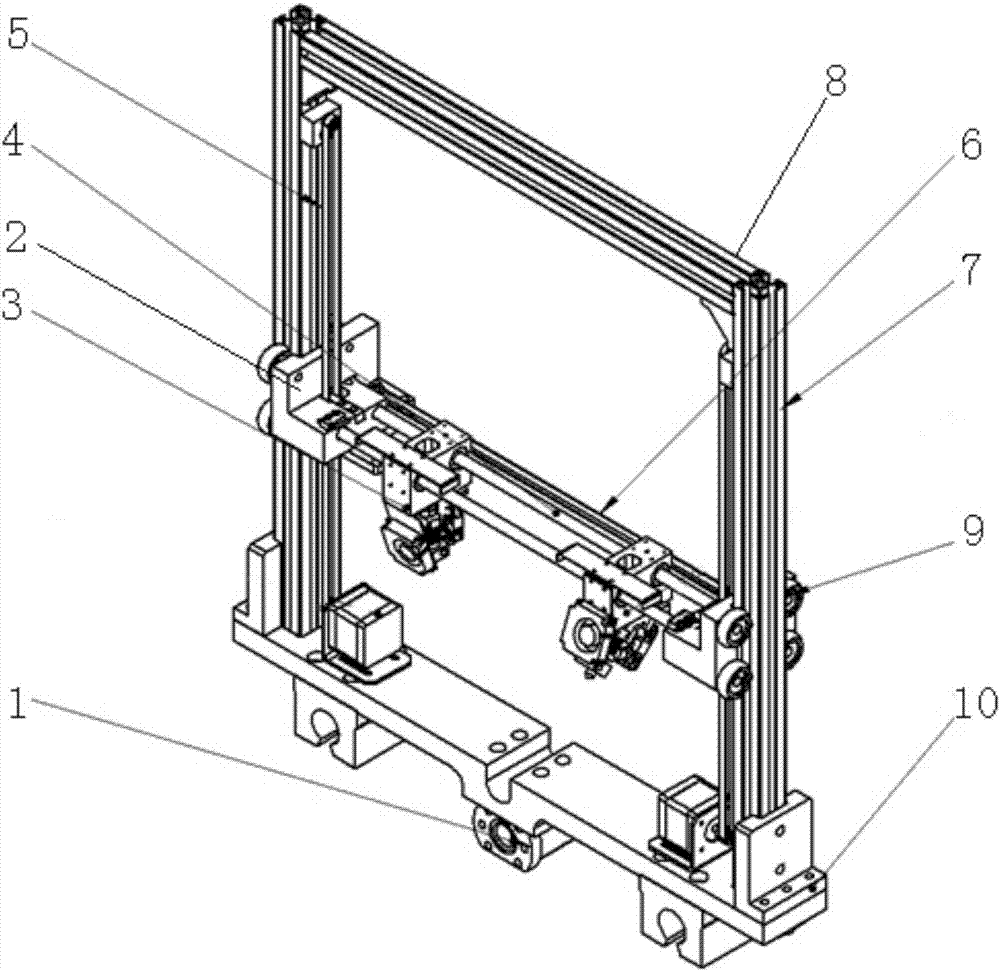

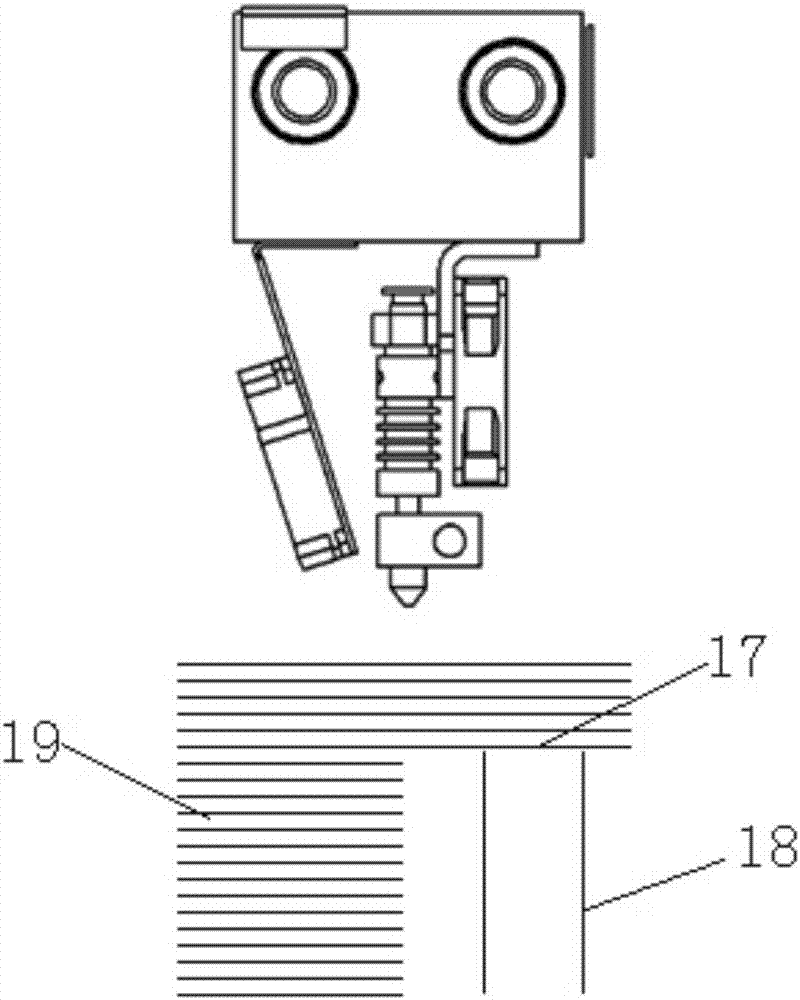

[0022] When printing an infinitely long object, the assembly line 14 needs to be moved forward by a distance corresponding to the height of the layer for each layer of printing. A 45° nozzle is used and the slicing direction is 45°.

Embodiment 2

[0024] When printing batch products, each gantry can be operated separately, the same object can be printed at the same time, and different objects can be printed independently. After the object is printed, the assembly line 14 moves forward. When the printed object moves to the edge due to the curvature, it can be Automatic peeling.

Embodiment 3

[0026] When multiple gantry cooperate to print the same object at the same time, the object is divided into several copies when slicing, and the number of copies is determined according to the number of gantry. At this time, the installation angle of the nozzle 3 is required to be in the vertical pipeline direction, parallel to the printing plane. Algorithmic stitching is performed on the boundaries of the segmented regions.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap