Vane pump rotor quenching device

A technology of quenching device and vane pump, which is applied in the direction of quenching device, furnace type, heat treatment equipment, etc., can solve the problem of opening the discharge switch at regular intervals, troubles, etc., and achieve the effect of reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below by means of specific embodiments:

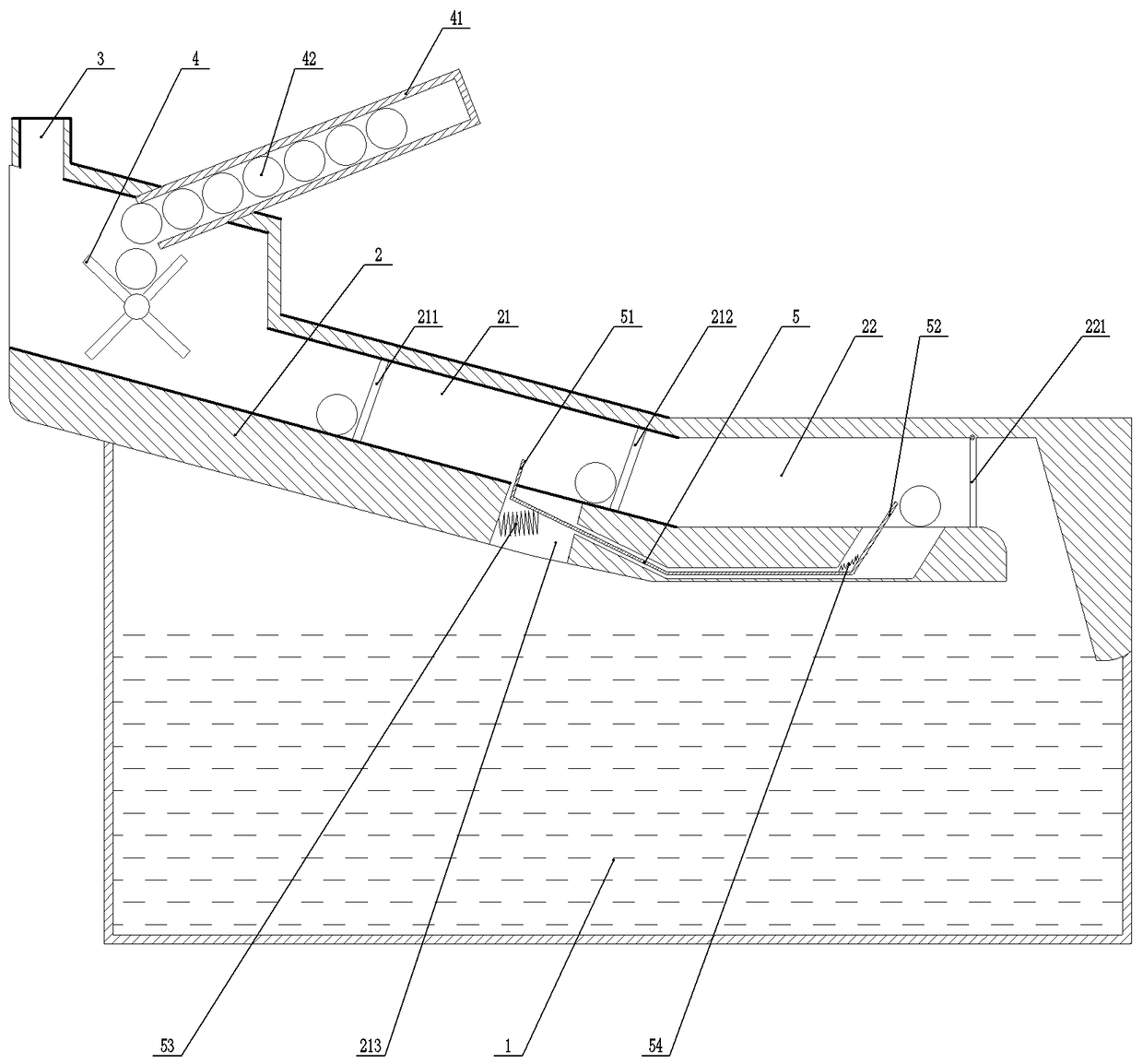

[0023] The reference signs in the drawings of the description include: quenching oil pool 1, furnace body 2, chute section 21, first material door 211, second material door 212, through hole 213, flat section 22, third material door 221, Smoke outlet 3, flip feeding rack 4, feed section 41, vane pump rotor 42, slide plate 5, drive plate 51, push plate 52, extension spring 53, spring 54.

[0024] Such as figure 1 As shown, the vane pump rotor quenching device includes a feeding unit, a quenching oil pool 1, a smoke exhaust unit and a furnace body 2. The outer surface of the furnace body 2 is covered with a heat insulation layer. The setting of the heat insulation layer can effectively prevent the furnace body from 2. The heat inside is dissipated to the outside, reducing energy loss. The body of furnace 2 comprises the chute section 21 and the flat section 22 which are i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com