Multifunctional assembly type physical similarity testing system for geotechnical engineering

A geotechnical and physical similarity technology, applied in the field of geotechnical engineering, can solve the problems of inability to disassemble, low utilization value, waste of materials and manpower, etc., to improve performance and use efficiency, save test costs, and facilitate adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

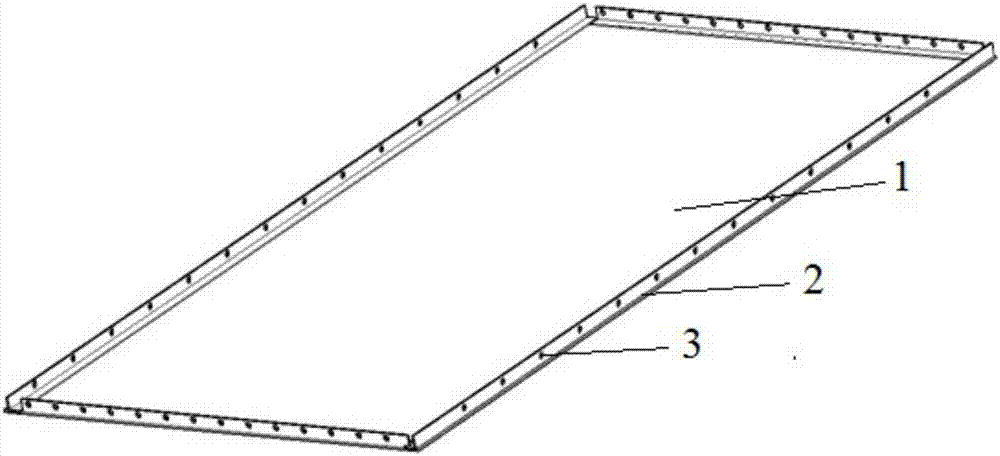

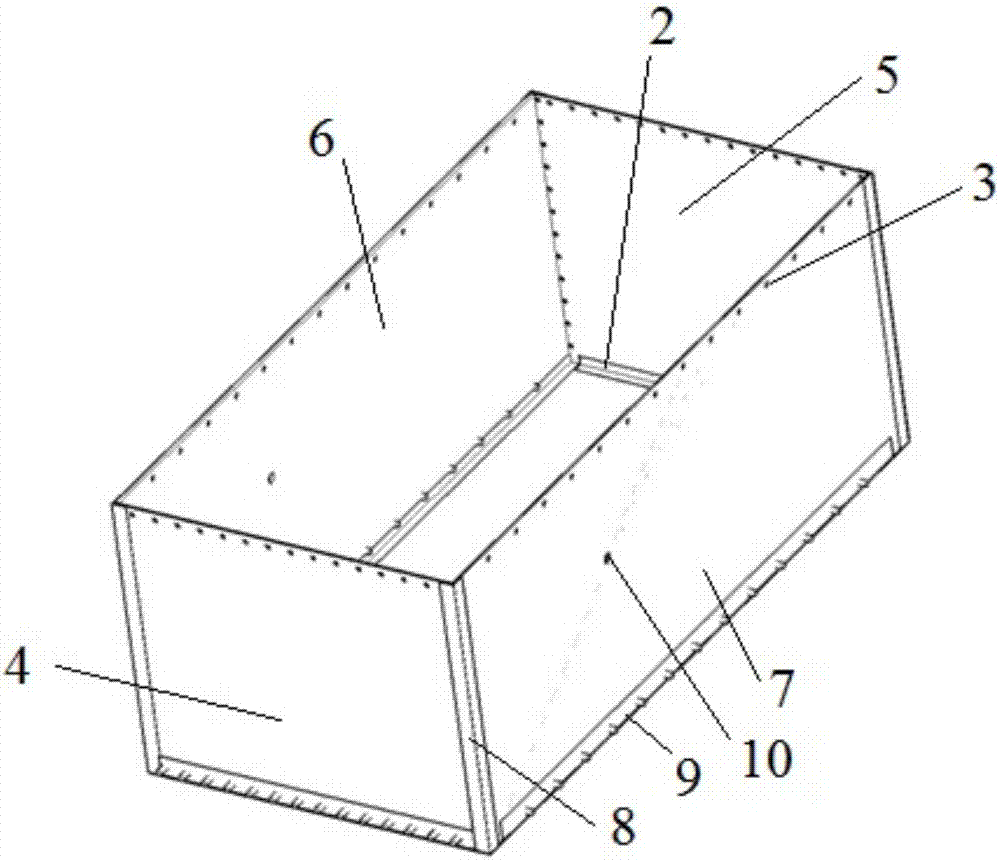

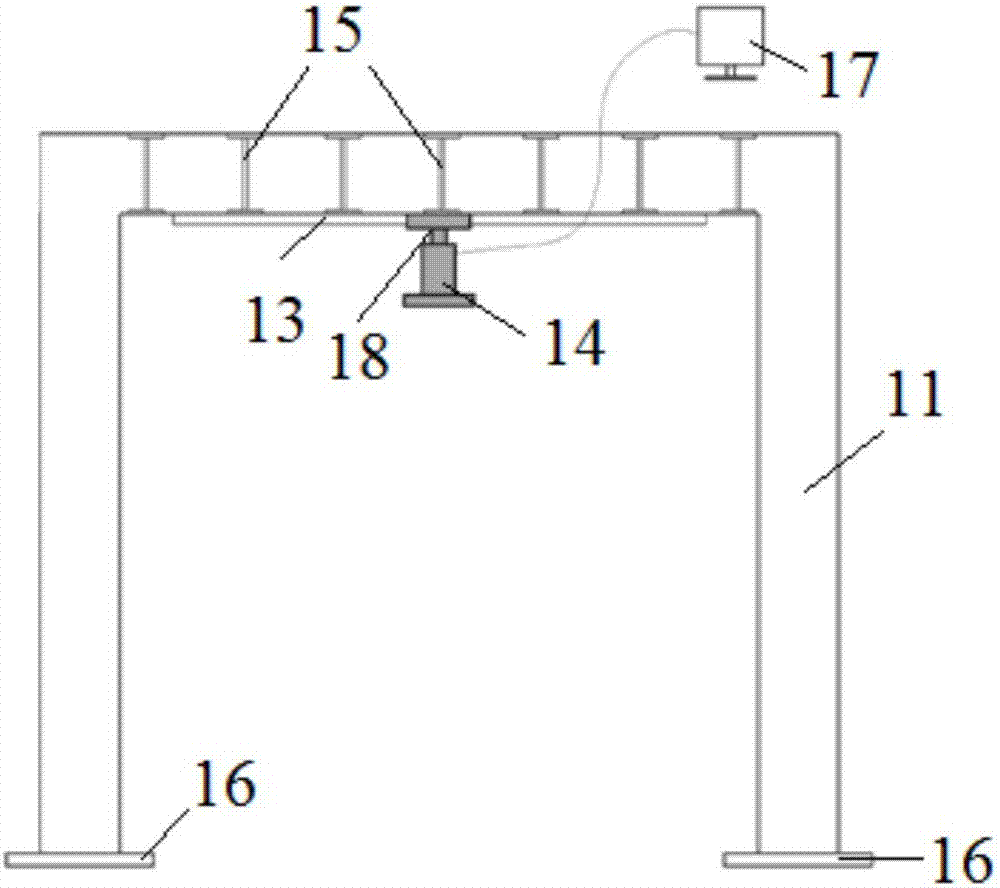

[0079] The multifunctional assembled geotechnical engineering physical similarity test system includes a model box, a loading device and a data acquisition device. The model box includes a left side panel, a right side panel, a front side panel, a rear side panel and a bottom panel; the left side panel , The right side plate, the front side plate, the rear side plate and the bottom plate can be detachably assembled into a box. The loading device includes a test frame, a sensor, a jack and a control panel. The upper part of the test frame can be slidably connected to the jack, that is, the jack can be along Horizontally and horizontally and / or horizontally and vertically slidingly arranged on the test frame and above the model box; the sensor includes a displacement sensor and a tension sensor, the displacement sensor is arranged on the jack, the tension pressure sensor is arranged above the jack, and the control panel is connected to the Control and record the data information o...

Embodiment 2

[0089] On the basis of Example 1, when the model box is in use, the model box can be properly heightened according to the needs of the test, such as Figure 5 As shown, the raised front side panel 401, the raised rear side panel 501, the raised left side panel 601, and the raised right side panel 701 are adopted. The lower edges of the four raised side panels correspond to the front, rear, left, and There are through holes at the upper end of the right side plate, and corresponding through holes are provided on the side edges of the adjacent heightening side plate. The connection between the heightening rear side plate 501 and the rear side plate 5 can be adopted by connecting the heightening rear side plate 501 and the rear side. The plate 5 is partially overlapped, and the through holes are fixed by bolts; steel strips with corresponding through holes on the upper and lower ends can also be used, and the rear side plate and the rear side plate are respectively fixed with the th...

Embodiment 3

[0094] When using the multi-functional assembled geotechnical engineering physical similarity test system of Example 1 for test simulation, the model box should be assembled first, and the left and right side panels, front and rear side panels of the model box should be fixed to the bottom plate by bolts according to the position. On the upper side, the side plates are bolted with L-shaped steel, and steel strips are added on the opposite side of the L-shaped steel to prevent stress concentration at the bolts.

[0095] When laying the experimental research substrate, if the research substrate is a soil layer, it can be divided into two situations: When the soil layer is sandy soil, the sand rain method can be used for laying, and the porosity of the soil body should be checked every time it reaches a certain height to ensure The uniformity of the soil layer; every certain height, a certain thickness of colored sand is evenly spread on the side close to the side plate where the ima...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com