Rotor alternate-angle stator magnetic isolation type axial permanent magnet auxiliary double-salient-pole motor

A double salient motor, angular stator technology, applied to synchronous motors with stationary armatures and rotating magnets, magnetic circuit shape/pattern/structure, magnetic circuit, etc., can solve the torque ripple of ordinary salient reluctance motors Large, magnetic flux loss wastes energy and other problems, to achieve good magnetic permeability, reduce copper loss, reduce the effect of reducing the moment of inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

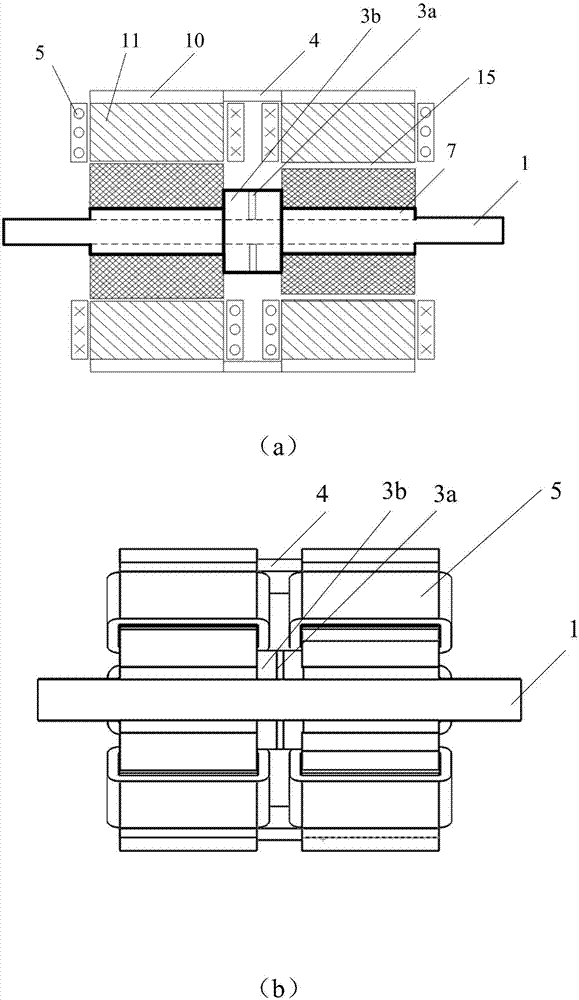

[0031] An embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

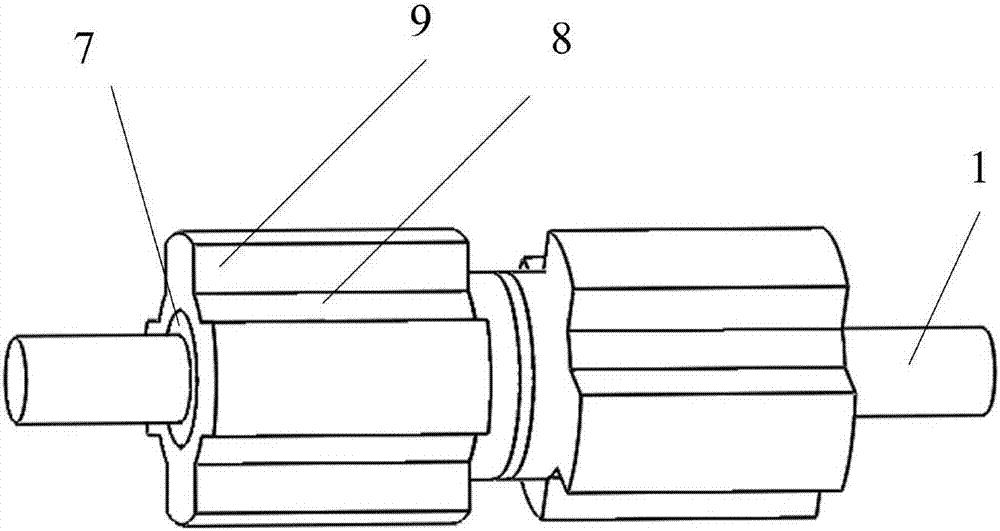

[0032] like Figure 1-9 As shown, a rotor staggered stator magnetic isolation axial permanent magnet assisted doubly salient motor, comprising:

[0033] Two sets of magnetic isolation stators, two sets of circumferentially staggered rotors, a rotating shaft 1, a casing 2, an axial ring-sleeved composite permanent magnet 3, a magnetic strip 4, an excitation winding 5 and an end cover 6.

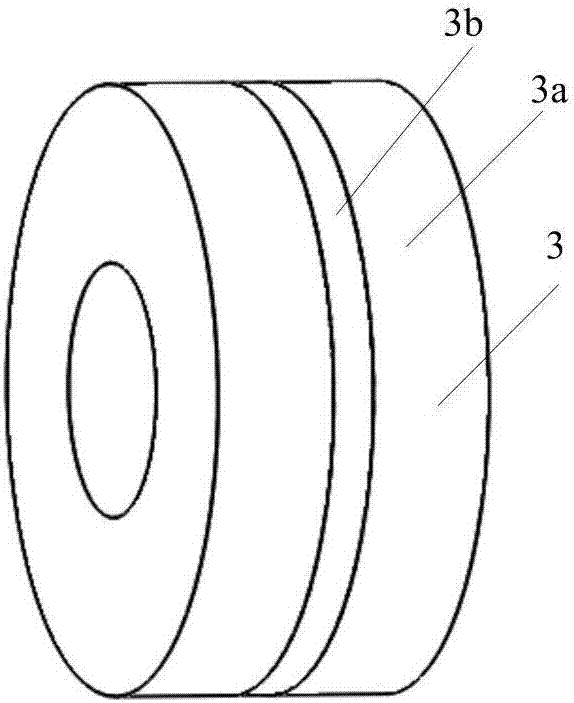

[0034] like figure 2 As shown, the axial ring-sleeve type composite permanent magnet 3 includes a permanent magnet 3b and a magnetic conductor 3a bonded at both ends thereof, and the axial ring-sleeve type composite permanent magnet 3 is ring-sleeved at the central position of the rotating shaft, and there is a space between it and the rotating shaft. A certain gap; the magnetic conductive material 3a is made of magnetic conductive material.

[0035] The rotating s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com