Traction box of a railway vehicle with a cooling system, associated application method and railway vehicle

A technology for railway vehicles and traction boxes, applied in the field of railway transportation, can solve problems such as difficult to cool electrical equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

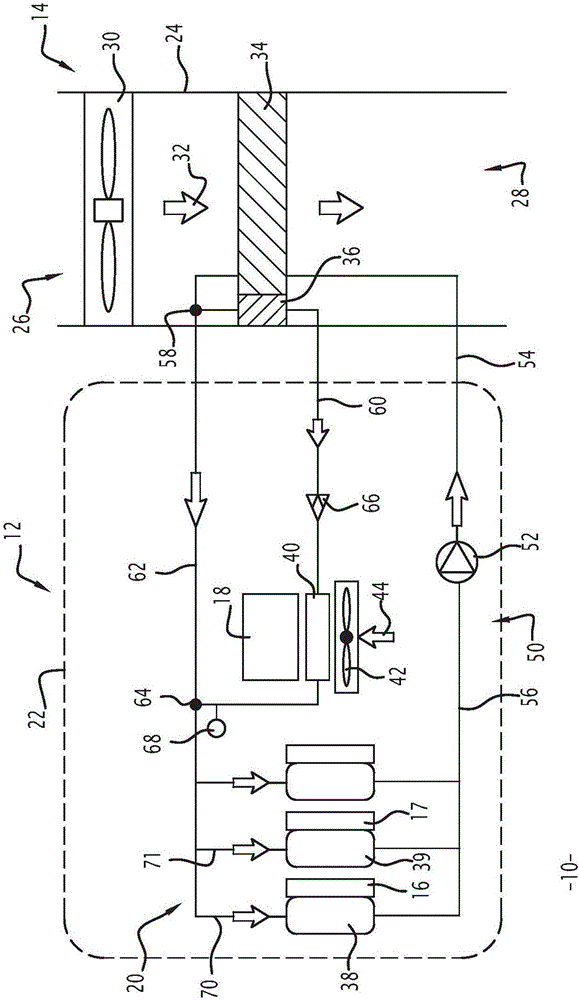

[0024] figure 1 A schematic front view of a traction box 10 of a railway vehicle according to an embodiment of the invention is shown.

[0025] The tank 10 includes a closed compartment 12 and a vent string 14 . The box 10 also comprises a first electrical equipment part 16 , 17 and a second electrical equipment part 18 arranged in the closed compartment 12 .

[0026] The box 10 further comprises cooling means 20 capable of removing the heat dissipated, in particular in the enclosed compartment 12 by said first 16 , 17 and second 18 parts of electrical equipment.

[0027] The cooling device 20 is arranged in the closed compartment 12 and in the ventilation string 14 .

[0028] Closed cabin 12 through the figure 1 Defined by the cover 22 shown in dotted line. Preferably, enclosure 22 is airtight. Thus, the air present inside said hood 22 is confined within the closed compartment 12 .

[0029] The second electrical equipment component 18 preferably includes elements for wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com