Grain unloading device of harvester

A grain unloading device and harvester technology, applied in harvesters, cutters, agricultural machinery and implements, etc., can solve the problems of grain pollution, oil leakage of hydraulic cylinders, etc., and achieve the effect of avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

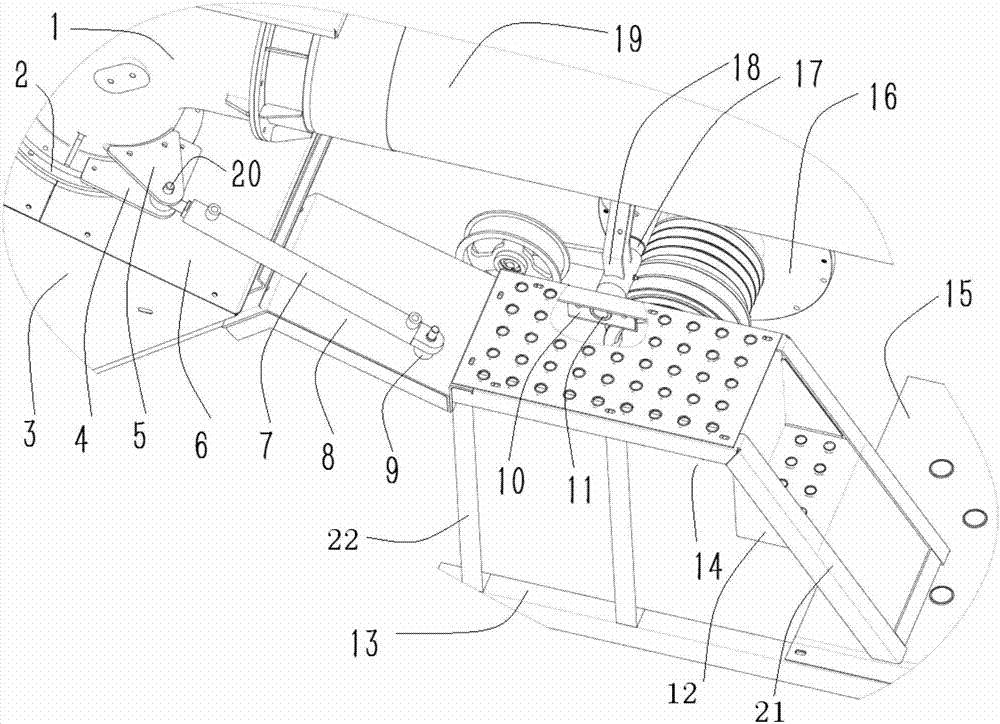

[0021] like figure 1 As shown, the grain tank 3 is fixed to the frame platform 15, the grain unloading cylinder 19 is located above the grain tank 3, the end of the grain unloading cylinder 19 is fixedly connected to the rotary elbow 1 by bolts, and the position of the entrance of the rotary elbow 1 and the outlet of the grain tank 3 Correspondingly, this is the prior art. Hydraulic cylinder 7 (comprising supporting hydraulic element, hydraulic pipeline) is positioned at the outside of grain tank 3, and the cylinder rod end of hydraulic cylinder 7 is hinged with swivel elbow 1, and the cylinder end of hydraulic cylinder 7 is hinged with holder 8. During specific implementation, the lower part of the swivel elbow 1 is provided with a boss, the boss is provided with a mounting hole, the upper connecting plate 5 and the lower connecting plate 4 are provided with a mounting circular hole, and the upper connecting plate 5 and the lower connecting plate 4 pass through the bolts. Co...

Embodiment 2

[0025] like figure 1 As shown, the drive unit of the grain unloading cylinder includes a motor, a clutch support shaft 17, a clutch arm 18, and the motor output end 16 is fixedly connected to the motor. Engine output end 16 is provided with clutch supporting shaft 17, and clutch rotating arm 18 is installed on the clutch supporting shaft 17, and the parts installed on clutch rotating arm 18 and its top can rotate with clutch supporting shaft 17. The clutch arm 18 is connected with the clutch control device, and the driver can operate the control device in the cab so as to realize the rotation of the clutch arm 18 and the opening and closing of the clutch, which is prior art.

[0026] In the second embodiment, the maintenance ladder 14 is located on the left side of the engine, and the top pedal of the maintenance ladder is provided with a support seat, which is used to support the clutch support shaft 17 of the grain unloading cylinder drive unit. The support seat is composed...

Embodiment 3

[0028] The difference between the third embodiment and the second embodiment is that the two ends of the fixing base 8 are provided with waist holes for adjusting the installation position. The seat plate 10 is provided with a horizontal waist hole for adjusting the installation position, and the maintenance ladder top surface pedal is correspondingly provided with a vertical waist hole for adjusting the installation position.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com