Yak sourly-extracted dried meat floss and preparation method thereof

A technology of yak meat and yak, which is applied in the field of yak sour pressed meat floss and its preparation, can solve the problems of meat floss sticking, poor taste, etc., and achieve the effects of good shape of meat floss, increased blood oxygen carrying capacity, and good food and medicine function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

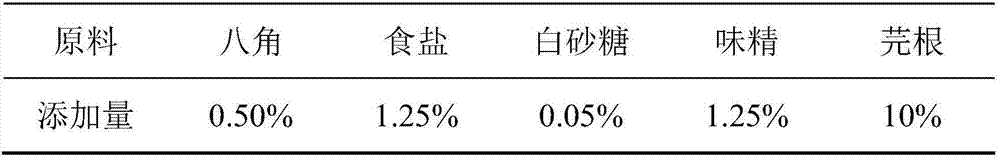

[0036] (1) Take sour yak meat and coriander root, add 2000ml of water to the pot, add yak sour meat and other ingredients into the ultrasonic cleaning machine according to the ratio in Table 1, the ultrasonic intensity is 90-180w / m2, and cook in boiling water 10-20min.

[0037] Table 1

[0038]

[0039] (2) Place the product obtained in the above step (1) under natural conditions (at a temperature of about 20° C.) to evaporate its surface moisture. After the surface moisture is completely evaporated, put it into a microwave oven to heat and evaporate its moisture to 20%. (Microwave firepower: medium-low fire; microwave time: 1min.)

[0040] (3) Grind the product obtained in the above step (2) through a universal pulverizer, set the gear of the universal pulverizer to low, and the pulverization time is about 2s, which can be adjusted according to the specific situation, until the meat floss presents a good flocculent shape, and the fibers present Just in a soft and fluffy ...

experiment example 1

[0064] Sensory Index

[0065] According to the sensory index requirements of GB / T23968-2009 and other related documents, the shape of meat floss should be flocculent, the fibers should be soft and fluffy, no scorching is allowed, and there can be a small amount of knots that do not affect the sensory evaluation. Excessive, scorched, sugar lumps and other phenomena are regarded as unqualified meat floss; in terms of color, good quality meat floss should be light yellow or golden yellow, and the color should be basically uniform. When the color is dark black, it is an unqualified product ; In terms of taste and smell, qualified meat floss should have the characteristics of delicious taste, moderate saltiness and sweetness, pure fragrance and no bad smell. sour taste.

[0066] Carry out sensory evaluation to embodiment 1 and comparative examples 1~4, the result is as follows:

[0067] The meat floss in Example 1 has a good shape and no knots; it has no pungent flavor of coriand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com