Draw-bar box wheel collection and ejection device

A trolley case and wheel technology, which is applied in the field of retractable and pop-up structure of trolley case wheels, can solve the problems of unstable placement of trolley cases, lack of frictional force boxes, and inability of boxes to stick closely together.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The following will further describe in detail a trolley case wheel retractable pop-up structure in conjunction with the accompanying drawings and embodiments.

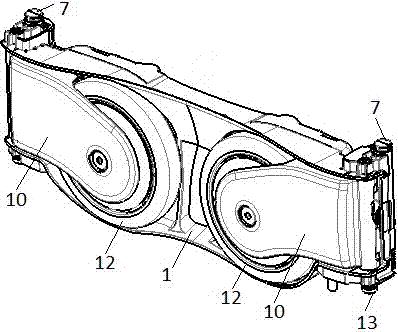

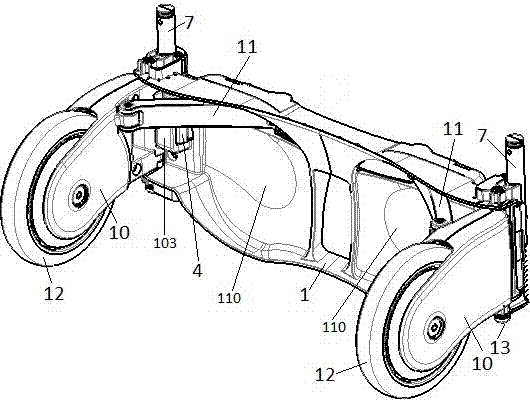

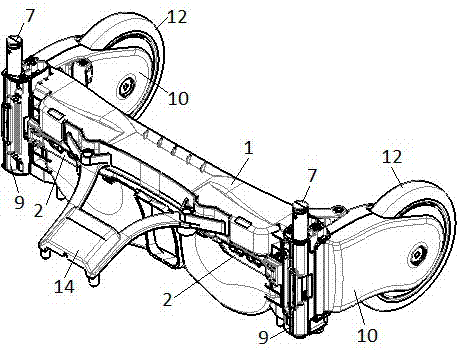

[0055] A trolley case wheel retractable pop-up structure, characterized in that it includes a frame 1, a driving paddle 2, a paddle spring 3, a lock 4, a lock spring 5, a piston pin 6, a piston shell 7, a piston spring 8, a piston Back cover 9, wheel fork 10, support bar 11, wheel 12, wheel fork rotating shaft 13, frame back cover 14.

[0056] According to the overall function, it is divided into five sub-assemblies: the frame assembly is composed of frame 1 and frame back cover 14, and its function is to provide a supporting base for the entire assembly; the driving paddle 2 and paddle spring 3 form the driving paddle assembly, and its The function is to provide the initial starting action for the wheel to pop up; the lock 4 and the lock spring 5 form a lock assembly, and its function is to lock the wheel when ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com