Cable rolling mechanism

A cable roller, rolling technology, applied in the direction of roller, cable/conductor manufacturing, electrical components, etc., can solve the problems of low processing efficiency, long process flow, complex processing process, etc., and achieve the effect of poor forming effect and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

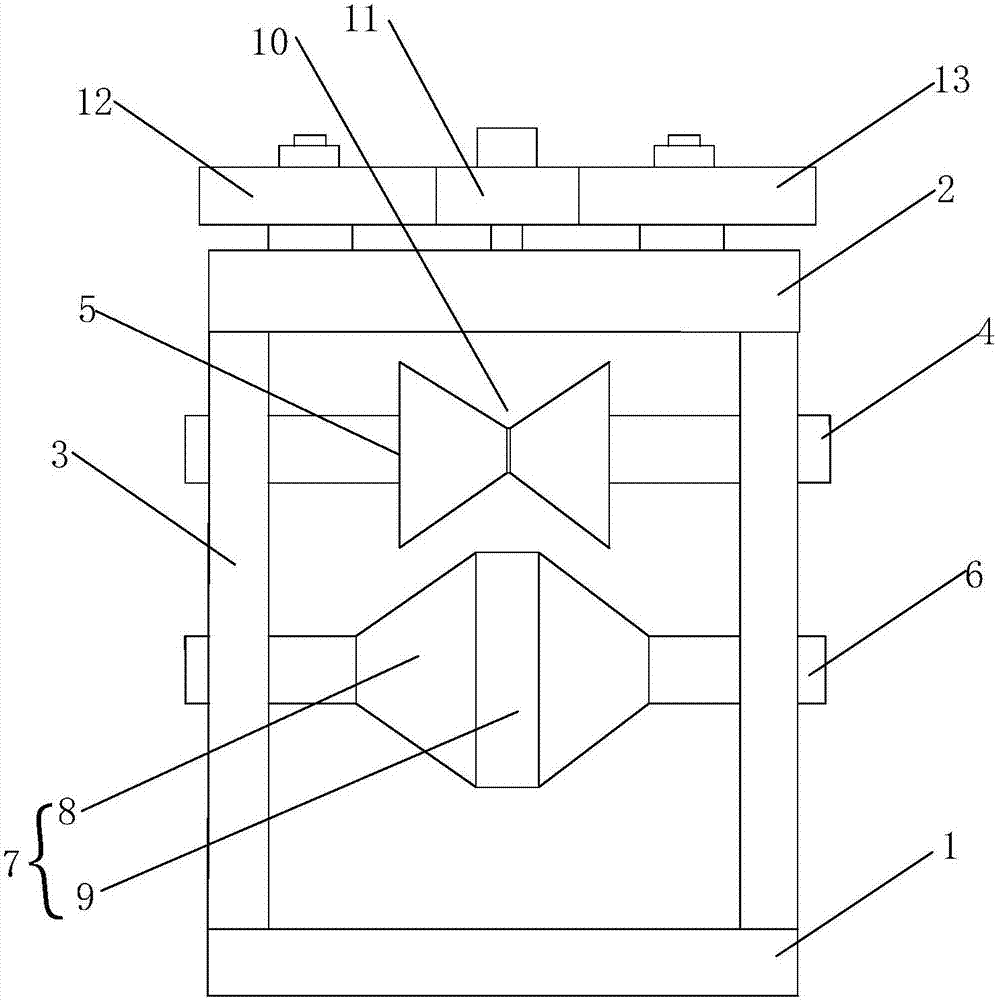

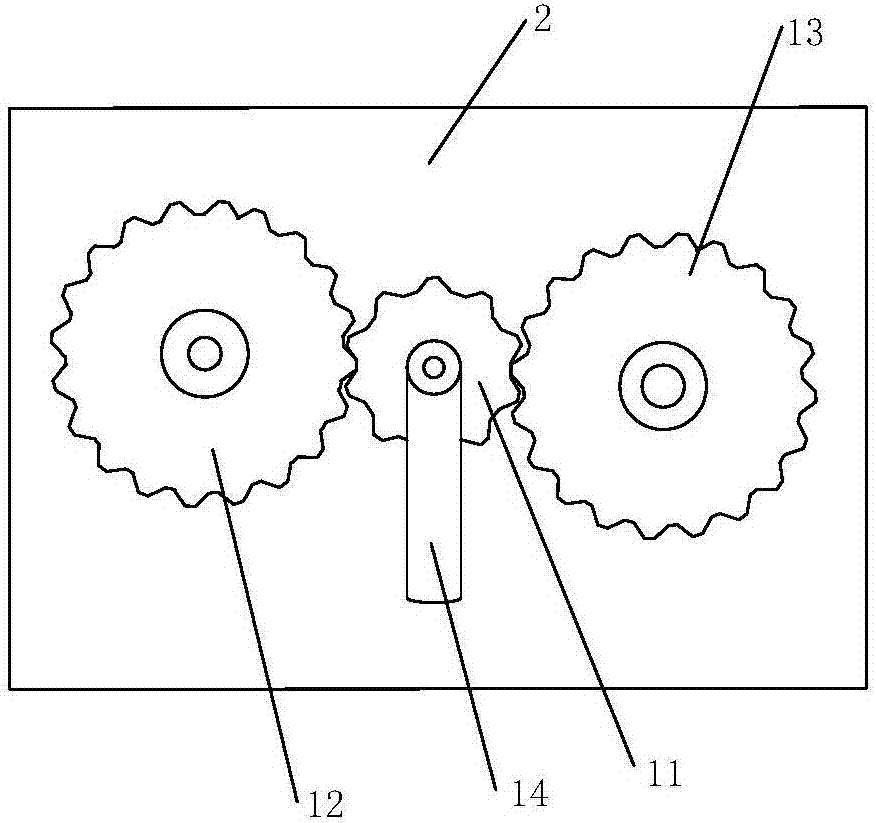

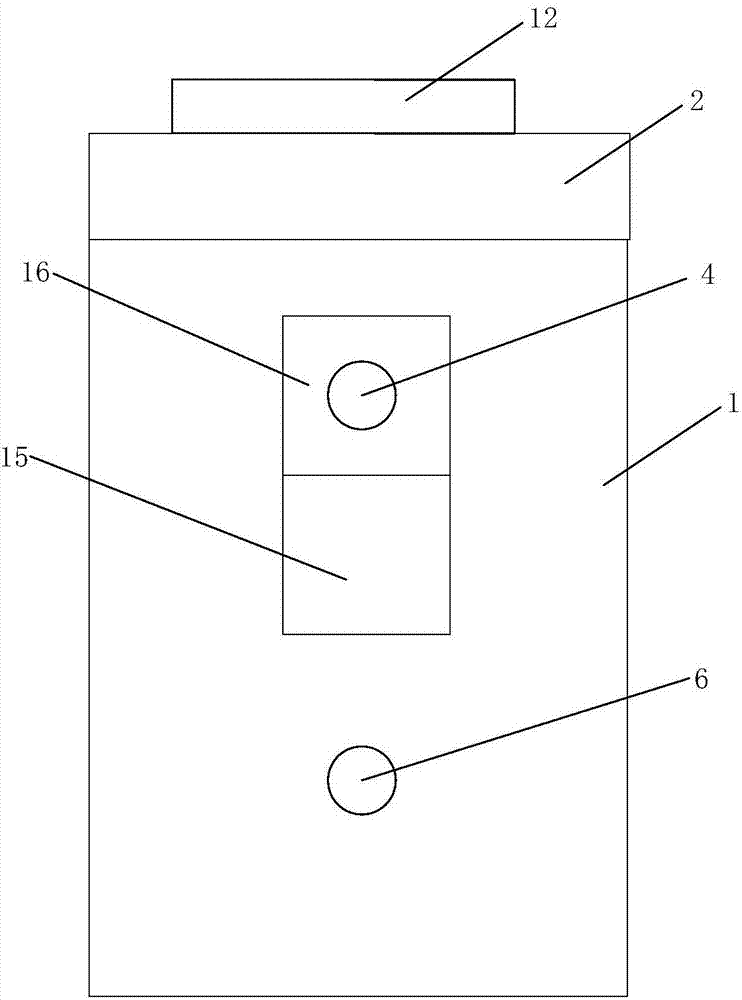

[0016] see Figure 1-Figure 5 , a cable rolling mechanism, including a hollow frame and an adjustment structure arranged on the hollow frame, the frame is composed of an upper seat 2, a lower seat 1 and two side plates 3 vertically parallel to each other, the two The side plates 3 are correspondingly provided with sliding grooves 15, and sliding blocks are installed in the sliding grooves 15. The lower seat 1 and the two side plates 3 form a rectangular waste chip groove, and the waste chips will automatically fall into the waste chips during use. in the slot. The hollow part of the frame is provided with an upper rolling structure and a lower roller 7 rolling structure that cooperate with each other up and down. The upper rolling structure includes an upper roller shaft 4 and a coaxial sleeve on the upper roller shaft 4. The upper roller 5 on the top, the outer surface of the upper roller 5 has an annular tapered groove 10; the lower rolling structure includes a lower roller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com